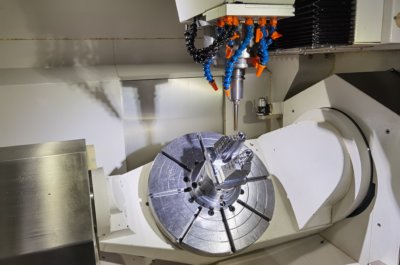

Exploring the universe of machining materials opens doors to an array of possibilities and challenges in the manufacturing sector. In this article we want to emphasize materials suitable for conventional machining, setting them apart from those used in CNC machining. Our journey will cover everything from the historical evolution of these materials to future trends […]

The injection molding process is not without its challenges, particularly when it comes to defects that can compromise quality. Recognizing and addressing injection molding defects is essential for manufacturers to ensure product quality, reduce waste, and optimize production efficiency. This guide goes deep into the most common issues, offering insights into their causes and outlining […]

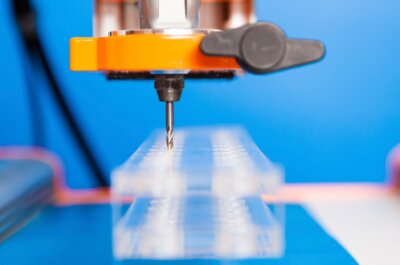

Acrylic (PMMA) is a highly desirable material due to its strength, toughness, and transparency. But relying on conventional machining processes to cut acrylic can be a complicated procedure: the material is highly fragile and any excess force can cause unwanted breakages. CNC machining, however, offers a reliable way to fabricate acrylic parts safely, with a […]

Rapid injection molding method is revolutionizing how products come to life, blending efficiency and speed with engineering. This process makes it possible to manufacture many durable consumer and industrial items cheaper than everything else. It produces around 32% of plastics by weight. What is Rapid Injection Molding? Rapid injection molding is a type of injection […]

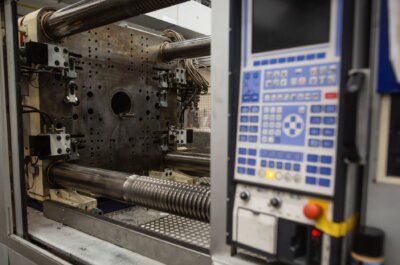

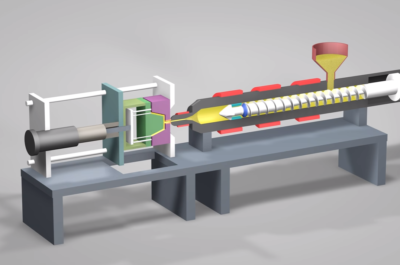

Diving into the world of manufacturing, one cannot overlook the pivotal role of injection molding machines. These devices are the unsung heroes behind the multitude of plastic products we use daily. From simple household items to intricate automotive components, the versatility and efficiency of injection molding machines make them indispensable in the production landscape. What […]

In the vast world of manufacturing, injection molding stands as an essential technique, used for creating a myriad of products with precision and efficiency. Let’s explore the multifaceted types of injection molding processes, each tailored for specific applications, materials, and advantages. The essence of injection molding, a process marrying innovation with technology, propels industries forward, […]

Dive into the art and science of mold making, an essential and intricate process that shapes the backbone of manufacturing industries worldwide. From the precision crafting of automotive parts to the delicate creation of medical devices, mold making enables the mass production of items with unmatched accuracy and consistency. This guide unravels the layers behind […]

For every CNC machining project, achieving the ideal surface finish is more than just an aesthetic choice—it’s an important factor that influences the functionality, durability, and performance of the machined parts. This comprehensive guide delves into the nuances of CNC surface finishes, offering insights into processes, comparisons, and the selection of suitable finishes for various […]

In the realm of modern machining, CNC drilling stands as a cornerstone, blending precision with efficiency to revolutionize how we create. This article delves into the essence, workings, and vast applications of CNC drilling, offering insights into its types, operations, and the machinery that powers it. Join us as we explore the intricacies of CNC […]

CNC routing stands as a pivotal advancement in manufacturing, offering unparalleled precision and versatility. This article delves into the essence, history, workings, and impact of CNC routing, a cornerstone in modern fabrication techniques. What is CNC Routing? At its core, CNC routing is a type of CNC machining process that utilizes computer numerical control to […]

In today’s fast-paced and increasingly customized world, low volume manufacturing stands as a beacon of flexibility and innovation. This manufacturing approach, unlike its high-volume counterpart, allows businesses to produce smaller quantities of products, catering to specific market demands and niches. In this extensive exploration, we’ll dive deep into what low volume production is, its significance, […]

Electrical Discharge Machining (EDM) represents a fascinating fusion of electricity and precision engineering, revolutionizing how we approach manufacturing complex components. This article aims to demystify EDM, a technique less familiar yet integral to modern manufacturing, by exploring its processes, applications, and evolution. From intricate aerospace components to delicate medical devices, EDM’s role is pivotal in […]

In the realm of machining and metalworking, the grinding machine stands as a pivotal tool, central to shaping and refining a multitude of materials. This article delves into the essence of grinding machines, unraveling their history, mechanism, types, and applications in a detailed exploration. What is a Grinding Machine? A grinding machine, often known as […]

In the realm of manufacturing and engineering, the term ‘surface finish’ plays a pivotal role. Often referred to as surface texture, this concept embodies the array of physical properties and characteristics defining the final appearance and feel of a product’s surface. Whether it’s about ensuring aesthetic appeal or meeting functional requirements, understanding surface finish is […]

CNC grinding, a process that marries the precision of computerized numerical control with the intricate world of grinding, stands as a cornerstone in modern machining operations. This guide delves deep into the realm of CNC grinding, exploring its history, mechanisms, and the myriad of applications it serves in today’s manufacturing landscape. Just as water is […]

Quality testing and inspection in CNC machining applications represent a critical phase, ensuring every machined component meets the high standards of precision and excellence. This article dives into the intricate world of quality testing and inspection, elucidating its significance, methodologies, and the innovations shaping its future. What is Quality Testing and Inspection in CNC Machining […]

In an era where precision and efficiency are a must, small batch machining stands out as a cornerstone of modern manufacturing. This article delves into the intricacies of small batch CNC machining, exploring its evolution, processes, and its pivotal role in today’s production landscape. What Is Small Batch Machining? Small batch machining, a type of […]

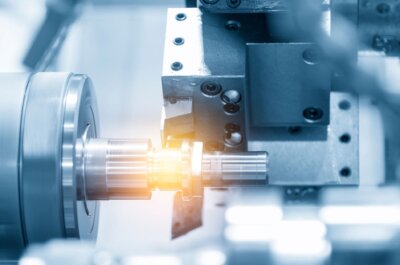

When delving into the world of machine tools, the lathe stands out as a fundamental and versatile device. Its ability to shape materials into precise forms has been pivotal in numerous industries, from intricate watchmaking to robust aerospace components. This extensive guide aims to unravel the intricacies of the lathe, exploring its history, functioning, types, […]

The world of modern machining is a realm where precision meets innovation, and at the heart of this technological marvel lies the CNC Lathe – a cornerstone in advanced manufacturing. This article delves deep into the essence of CNC lathes, exploring their history, functionality, types, and much more, unraveling the complexities of these sophisticated machines. […]

Grinding, a term synonymous with precision and efficiency in material removal, stands at the forefront of modern manufacturing techniques. This article delves into the grinding process, exploring its mechanics, applications, and evolution. What is Grinding? Grinding is an intricate abrasive machining process involving an abrasive wheel as a cutting tool. It’s renowned for its ability […]

Computer Numerical Control (CNC) machining stands as a cornerstone in modern manufacturing, a process where pre-programmed software dictates the movements of factory tools and machinery. The precision and efficiency of CNC machining and modern CNC milling tools have revolutionized production, yet the intricate nature of these operations brings inherent challenges, notably in the form of […]

Thermoplastic injection molding offers a versatile and efficient method for mass-producing plastic parts. This guide delves into the intricacies of this technique, exploring its applications, advantages, and the science behind turning raw plastic into durable, functional components. What is Thermoplastic Injection Molding? Thermoplastic injection molding is a transformative process where thermoplastic polymers are melted, injected […]

Injection molding and urethane casting posses unique attributes and applications, shaping the world of production in distinct ways. Injection molding, a method known for its precision and efficiency in mass production of plastic products, contrasts sharply with urethane casting, celebrated for its flexibility and suitability for low-volume production This article delves into the depths of […]

Injection molding and extrusion stand as pivotal manufacturing processes in the plastic industry, each with unique characteristics and applications. In this detailed exploration, we aim to dissect these methods, highlighting their distinct nature and operational principles. These processes, fundamental in shaping countless products around us, from intricate medical devices to robust automotive parts, represent the […]

The manufacturing world stands at a crossroads where precision meets innovation, particularly in the realms of Injection Molding and CNC Machining. Injection Molding and CNC Machining, while seemingly similar, operate on fundamentally different principles. Injection Molding, akin to casting, molds molten materials into predefined shapes. CNC Machining, in contrast, subtracts material through cutting and drilling […]

In the realm of manufacturing, particularly in the plastics industry, the durability and longevity of injection molds are pivotal for efficient production. Understanding the life expectancy of these molds is not just about numbers; it’s about grasping the intricate dance of material, design, and maintenance that dictates their lifespan. This article dives deep into the […]

The world of manufacturing was forever changed with the advent of injection molding, a groundbreaking technique crucial in shaping today’s plastic production landscape. This article delves into the rich history and transformative impact of injection molding, tracing its roots and exploring its pivotal role in the modern plastics industry. What Is Injection Molding? Injection molding […]

In the realm of manufacturing, injection molding tooling stands as a pivotal process, central to the production and manufacture of countless plastic components. This guide delves into the intricacies of injection molding tooling, unraveling its complexities and highlighting its significance in modern manufacturing. What is Tooling in Injection Molding? Injection molding tooling refers to […]

In the realm of modern manufacturing, CNC machining emerges not just as a method, but as a monumental shift in production philosophy. This technology, marrying the precision of computer algorithms with the robustness of machine tools, has not just enhanced but redefined the parameters of production. From its nascent sketches on paper to its current […]

Injection molding stands as a cornerstone in the manufacturing world, revolutionizing the production of parts across a myriad of industries. This method, known for its efficiency and versatility, shapes the way products are created, from everyday household items to intricate components in specialized fields. Injection molding, a manufacturing technique revered for its precision and scalability, […]

Copper, renowned for its electrical and thermal conductivity, plays a pivotal role in modern manufacturing and is a common material used in CNC machining. This guide delves deep into the world of copper machining, unraveling its intricacies, techniques, and applications. It’s not just about shaping a metal; it’s about harnessing copper’s unique properties to create […]

CNC Turning, or Computer Numerical Control Turning, is an important part of modern CNC machining processes and operations. This technology harnesses the precision of computer programming to manipulate lathe machines, transforming raw materials into meticulously crafted parts. CNC turning’s essence lies in its ability to produce cylindrical components with intricate details and high precision. At […]

In the realm of precision manufacturing, micro machining stands as a revolutionary technique, reshaping how we approach fabrication at microscopic scales. This in-depth guide delves into the intricate world of micro machining, exploring its principles, applications, and the remarkable precision it brings to modern engineering. What is Micro Machining? Micro machining, a term synonymous with […]

When delving into the world of manufacturing, the term ‘Injection Molding’ often surfaces as a cornerstone technique. Renowned for transforming industries with its precision and versatility, injection molding stands as a pillar of modern manufacturing. This article embarks on a comprehensive exploration of its numerous advantages, presenting a thorough insight into why it remains a […]

Injection molding, a cornerstone in the world of modern manufacturing, involves nuanced parameters that dictate its efficiency and quality. This guide dives deep into understanding and mastering these critical parameters. What is Injection Molding? Injection molding stands as a pivotal manufacturing process used extensively in producing complex and varied plastic parts. This technique involves melting […]

Machine tools are the foundation of modern manufacturing, offering precision, power, and unparalleled versatility in shaping materials. This guide goes deep into the world of machine tools, unraveling their significance, evolution, and the technological advancements that have shaped today’s industry. What Is a Machine Tool? A machine tool, a critical component in the machining process, […]

When we delve into the world of machine shops, we unearth a significant facet of industrial development, stemming from the depths of the Industrial Revolution to the modern era of CNC machining and beyond. This guide aims to provide a thorough understanding of machine shops, their evolution, functions, and their pivotal role in various industries. […]

The world of manufacturing is continually evolving, and at the forefront of this innovation is injection molding. A critical aspect that determines the success of this process is the selection of the right material. Understanding the nuances of different injection molding materials is not just a matter of technicality but a cornerstone of quality and […]

In the intricate world of manufacturing, molding stands out as a cornerstone technique, pivotal across a spectrum of industries. From the minutiae of micro-components to the expanse of automotive parts, molding has been instrumental in shaping not only materials but also the evolution of modern manufacturing. What is Molding? Molding, often interchangeably used with ‘moulding’, […]

In the world of manufacturing, a machining center (MC) serves as the cornerstone for modern industrial applications. But what exactly is a machining center, and how does it contribute to the field of CNC machining? This comprehensive guide will explore the nuances of machining centers, their functions, types, components, and much more, providing you with […]

Navigating the world of CNC machining can be a complex task, especially when it comes to understanding the intricacies of programming language like M code. In this ultimate guide, we’ll delve into everything you need to know about M code, a critical component in CNC programming. Whether you’re a seasoned machinist, an aspiring CNC programmer, […]

Modern sectors like architecture, engineering, and manufacturing rely on computer programs to create designs of various parts and prototypes. Therefore, understanding ‘what is g code’ becomes essential for anyone dealing with the area of Computer Numerical Control (CNC), 3D printing, or any computer programming language for designing machining parts. This article will have an in-depth […]

All CNC machines rely on G-code for their functioning. Contrary to what some people believe, G-code for CNC machine is not a difficult concept. It is very easy to understand the basics of G-code, how it works, and how to create a G-code for your next project. Keep reading to find out everything there is […]

Injection molding allows manufacturers to create plastic parts from a wide range of thermoplastic polymers. But what about when the product is better suited to a thermosetting polymer like a polyurea or polyester? Thermoplastic pellets can be melted down and injected into a mold cavity, where they harden, but thermosets do not behave in this […]

In a world that thrives on efficiency and precision, businesses are perpetually on the hunt for methods that deliver optimal results with minimal investment. One such innovation that has dramatically transformed the manufacturing industry is CNC machining. Standing for Computer Numerical Control, CNC is a process used in manufacturing where pre-programmed computer software dictates the […]

Navigating the intricate labyrinth of CNC machining services can be a daunting task. Your choice can either steer your project towards success or throw it into the whirlwinds of failure. CNC machining services are primarily delivered in specialized CNC machine shops. A CNC machine shop is usually equipped with technologically advanced equipment and offers precision […]

Turning, a term that resonates throughout the industry, a technique that has paved the way for modern machining and has become the cornerstone of mechanical engineering. With a single point cutting tool and a rotating workpiece, it opens up a world of precision cuts and intricately shaped components. This article will unravel the ins and […]

Milling is one of the most popular machining processes. Milling machines are present in almost every machining workshop. The benefits and capabilities of these machines are far-reaching. People new to the industry often ask what is milling, its working process, and its various types. This article will have an in-depth discussion on the milling technology. […]

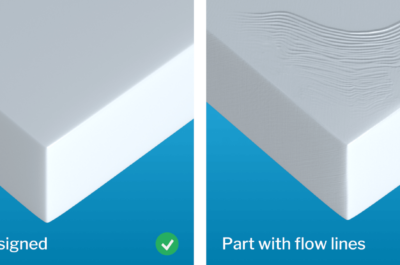

Flow lines or flow marks are a common visual defect in injection molding. Manifesting as wavy lines or streaks on the surface of the molding, flow lines generally occur when molten material flows unevenly and when some areas of the molding cool faster than others. Although flow lines shouldn’t affect tolerance or the structural integrity […]

Picture this: a sophisticated system where design, manufacturing, and quality control are seamlessly integrated to provide maximum efficiency in production processes. This isn’t a far-off dream, but a current reality known as Computer-Aided Manufacturing (CAM). This comprehensive guide will delve into the exciting world of CAM, unravel its history, demonstrate its workings, benefits, and future […]

As we stand at the crossroads of technology and creativity, a paradigm shift is palpably reshaping how we design and create. Nestled at the heart of this revolution is a powerful tool that has radically changed the face of multiple industries: Computer-Aided Design (CAD). But what exactly is this much-discussed tool, and why all the […]

CNC machining fulfils the need for a wide variety of services. For this purpose, CNC machines come in many different versions. Among these options, 3-axis CNC, 4-axis CNC, and 5-axis CNC machining are the most common options. Professionals often wonder about the best choice between 3 vs 4 vs 5-axis CNC machining. This article will […]

Manufacturing processes are vital to meet demand for various consumer goods. Evolving technology and computing is rapidly changing the manufacturing scene. Manufacturers and professionals in the industry often query about the different processes available for them. This article will have an in-depth discussion on ‘what is manufacturing process?’ You will learn about the basics of […]

Machining operations run most of the manufacturing processes worldwide. They either create the final product completely or make the tools needed for manufacturing. Therefore, understanding machining processes is key to the skillful execution of your next manufacturing project. This article will discuss in detail the various types of machining operations. You can choose the right […]

In the thriving era of automation, 4-axis machining has paved its way into various manufacturing processes. It is intriguing, complex, yet crucial to understand the intricacies of this automated marvel. What is 4-Axis Machining? 4-Axis machining, commonly known as 4-axis CNC machining, is a multi-axis machining process that utilizes CNC machines equipped with an additional […]

In the sprawling arena of manufacturing and engineering, one technology that is rewriting the rules is 3-axis machining. But what exactly is this wonder of modern engineering? Dive in as we unravel the intricacies of this innovative technology. What is 3-Axis Machining? Fundamentally, 3-axis machining is a multi-axis machining process that involves the coordinated movement […]

Flash or flashing is one of the most common problems associated with injection molding, the most widely used manufacturing process for plastic parts. Injection molding flash is when a line of excess material builds up on the outside of a molded part, typically after leaking through the parting line of the mold. A small amount […]

Stainless steel is one of the most commonly used machining materials. Stainless steel machining creates products and tools for every sector out there. Stainless steel machining is not as easy as materials like wood. Stainless steel has a high hardness and tensile strength. Therefore, machining stainless steel requires understanding the different metalworking processes that work […]

Additive and subtractive manufacturing processes drive all global industries. All processes used in manufacturing fall into one of these two categories. Both come with their applications, advantages, and disadvantages. These factors are best understood by comparing additive manufacturing vs. subtractive manufacturing processes side by side. Therefore, professionals often enquire about the details of each of […]

CNC machining has revolutionized the world of manufacturing, offering unparalleled precision and efficiency. One material that has stood the test of time in this field is brass, an alloy of copper and zinc. With its excellent machinability and unique properties, it’s no wonder that brass is a popular choice for numerous applications. In this comprehensive […]

Brass, a versatile and widely used alloy, is primarily composed of copper and zinc. Its unique properties and advantages make it suitable for a wide range of applications, from decorative objects and hardware to plumbing fittings and marine components. With various types of brass available, each with distinct characteristics, this alloy continues to be a […]

Welcome to the fascinating realm of brass, an alloy that has shaped our world for centuries. This comprehensive guide will take you through the brass basics, delving into its history, unique properties, versatile applications, and more. So sit back, relax, and let us embark on a journey through the ages with this timeless alloy. What […]

In the world of machining, brass is one of the most versatile and sought-after materials for creating intricate and high-quality parts. This comprehensive guide will delve deep into the realm of brass CNC machining, exploring its advantages, brass grades and properties, tips for successful machining, available finishes, and factors to consider when choosing this process. […]

Plastic machining is one of the most common industrial processes due to the high usage of this material. However, modern-day plastic CNC machining isn’t what it used to be. Plastics nowadays can be built strong enough to stop a bullet’s impact. This calls for a very rugged machining method. CNC machining plastics has become a […]

Computer Numerical Control (CNC) has been one of the top innovations of the last few centuries. It has completely changed how manufacturing processes work. The level of automation it brings has provided a gateway to focus on skill-based labor instead of physical labor. If you wonder ‘what is computer numerical control’ and how it works, […]

CNC machining has become the central pillar of modern manufacturing processes. Most industries rely on this technology to handle the needs of multiple stages of production. From prototyping to mass production, CNC machining can do it all. However, many professionals wonder how this technology fares against other alternatives. One of the most queried comparisons is […]

CNC machines are the powerhouse of all modern manufacturing processes. CNC machines fit everywhere, from precision parts of prototypes to high-volume manufacturing models. This is why these machines have evolved into many different types to suit particular application requirements. Multiaxis CNC machines have become the preferred option among the many different types. They can manufacture […]

Standard machining tolerances are an important parameter to consider regardless of the product you are manufacturing. In this day and age, most consumer goods demand consistency on a micro-scale. Therefore, manufacturers often go through the various types of manufacturing processes and compare them while keeping the machining tolerances as a major factor. To understand the […]

Manufacturing is a centuries-old industry. However, the on-demand manufacturing model is quite a recent phenomenon. In a relatively short time, it has quickly become the preferred model in many industries, replacing traditional manufacturing processes. Due to the popularity of on-demand manufacturing, it is essential to understand the main features of this model in the manufacturing […]

CNC machining is nothing short of a miracle for manufacturers, providing high-speed manufacturing with complete automation and ultra-high precision. The countless benefits of the CNC machining process have made it applicable in many manufacturing industries. This article will answer the question: what are the different applications of CNC machining technology in various industries? What is CNC Machining? […]

CNC milling machines and Computer Numerical Control machining was the main pillar on which Industry 3.0 developed. CNC technology provides the opportunity for manufacturing processes that can meet astronomical production figures. Due to the vast benefits of CNC technology, it finds applications in almost every manufacturing industry regardless of scale. Manufacturers are always looking for […]

Milling has been the favorite manufacturing process for metalworkers since the 1800s. What has changed significantly is the way that it is done. A hundred years ago, milling required a lot of manual labor. But now Computer Numerical Control (CNC) technologies do most of the work. Generally speaking, once the tooling is set up, CNC […]

Our world is surrounded by complex technology evolving at a rapid rate. In everyday life, we see a lot of intricate parts, such as gears and components inside machinery, which makes one wonder what goes into manufacturing them. Well, for most of these products and to the question of how they are made, the answer […]

Over the years, there have been many advances in manufacturing processes. The Fourth Industrial Revolution has led to one of these – CNC machining and milling. CNC stands for Computer Numerical Control. CNC machines perform computer numerical control machining, a precision manufacturing process involving core-programmed computer software. The manufacturing industry, especially, benefits from CNC machining. […]

Online manufacturing platforms are the most popular places to order rapid prototypes and production parts, you just have to upload your 3D CAD files, fill in the information about material, quantity, and surface finish, and you will have the quotation in seconds. If you are happy with the price, you can order straight away. Online […]

Injection molding is the go-to manufacturing process for the mass manufacture of plastic parts. Central to the molding process is the plastic injection molding machine, a large piece of machinery that consists of two parts, an injection unit and a clamping unit. The injection molding process is fast, accurate, highly repeatable, and extremely cost-effective in […]

Maintaining the condition of the putting green is essential to a successful round of golf. Custom golf divot tools, made using 3D printing of CNC machining, are a great way to improve your putting game while personalizing the golfing experience. Few sports are as dependent on the condition of the playing field as golf. In […]

What is the cost of injection molding? This is a commonly asked question by people wondering about adopting this technology. Injection molding is a popular manufacturing process for creating many parts and components. As such, learning about the costs of producing an injection molded part is vital before considering this process for your manufacturing operation. This […]

From engine blocks to door handles, die casting is a fast, accurate, and repeatable metal production technique suitable for large or small parts. Die casting parts have an excellent surface finish, and the process is compatible with a range of non-ferrous metals. Because of the high startup costs associated with die casting, the process is […]