Our world is surrounded by complex technology evolving at a rapid rate. In everyday life, we see a lot of intricate parts, such as gears and components inside machinery, which makes one wonder what goes into manufacturing them.

Well, for most of these products and to the question of how they are made, the answer is the same – CNC precision machining.

Computer numerical control (CNC) processes have been the foundation stone for modern industries, producing parts in an automated fashion at unimaginable production speeds. CNC precision machining has taken it even further, adding accuracy and simplifying the manufacturing process.

This article will discuss precision machining, how to do it, the tools needed, and much more.

What is Precision Machining?

Precision machining is a type of machining process that uses computer-controlled machine tools for parts production. It is a high-velocity machining process to make parts requiring tight tolerances, high complexity, or both. Precision machining may be done by a skilled precision machinist operator or even high-speed robotics.

It is a subtractive manufacturing process where the machine starts with a block and removes material from it with a cutting tool. Precision machining is frequently used for making an assortment of parts that fit and work together.

Successful precision machining relies on a combination of two factors:

- Firstly, quality precision machining requires a high-end cutting tool capable of removing the material carefully to match the desired product dimensions.

- Secondly, the process requires a Computer Numerical Control (CNC) machine. Typically incorporating high-speed robotics, the CNC machine automatically controls the cutting tool, directing it where to cut/mill on the workpiece.

What are the Steps in the Precision Machining Process?

Most precision machining companies work through a series of similar steps for various types of parts.

1. Design the Graphical Model

A graphical model is required to create any part. This is accomplished with the help of Computer-Aided Design (CAD) software. The CAD software enables the designer to create 2D and 3D models of any part for manufacturing.

It is common for designs to start as hand-drawn sketches to understand the basic concepts of the part. The Computer-Aided Design (CAD) designer then refers to these sketches to create the graphical model with accuracy in dimensions. For Computer-Aided Design, there are many popular software programs, both free and paid. Manufacturers can also outsource the design process for any complex design development.

2. Convert CAD to CAM

Computer-Aided Design creates a graphical representation of the part in a digital format. This representation is easy for the designers, operators, and manufacturers to understand. However, CNC machines used to create the part do not understand this digital format directly.

The machine understands coordinates where it can move the cutting tool or shift the workpiece. Therefore, CNC machines require the part design to be in a suitable format that provides the necessary manufacturing instructions. Computer Aided Manufacturing (CAM) software is used to create the readable format for CNC machining. The CAM software takes the CAD model and converts it into CAM format that the CNC machines can understand.

Computer Aided Manufacturing (CAM) software uses two types of codes – the G and M codes. The G code controls the coordinates of the cutting tool. The M code controls the auxiliary functions of the machine, such as turning the coolant flow on or off.

3. Machine Setup

Once the designs are ready in CAM format, it is time to do the machine setup. This will typically require machine tool calibration and mounting of the workpiece on the machine. The machine tools can vary based on the workpiece material and design of the final part. There are various precision machining tools available for different purposes. In this step, it is important to tighten all the clamps correctly and ensure the machine parameters, such as the coolant levels, are acceptable.

4. Execute the Machining

Once the setup is complete, the machine program is ready to execute. Most CNC machines have a display to monitor the program and adjust various parameters. When the program is executed, the CNC machine will begin the precision machining process.

5. Completion

Once the part is manufactured using the precision machine, it can be removed. Depending on the requirements, the part may be sent for secondary processes such as grinding or polishing. However, in most cases, a finished product created using precision machining does not need any secondary processing.

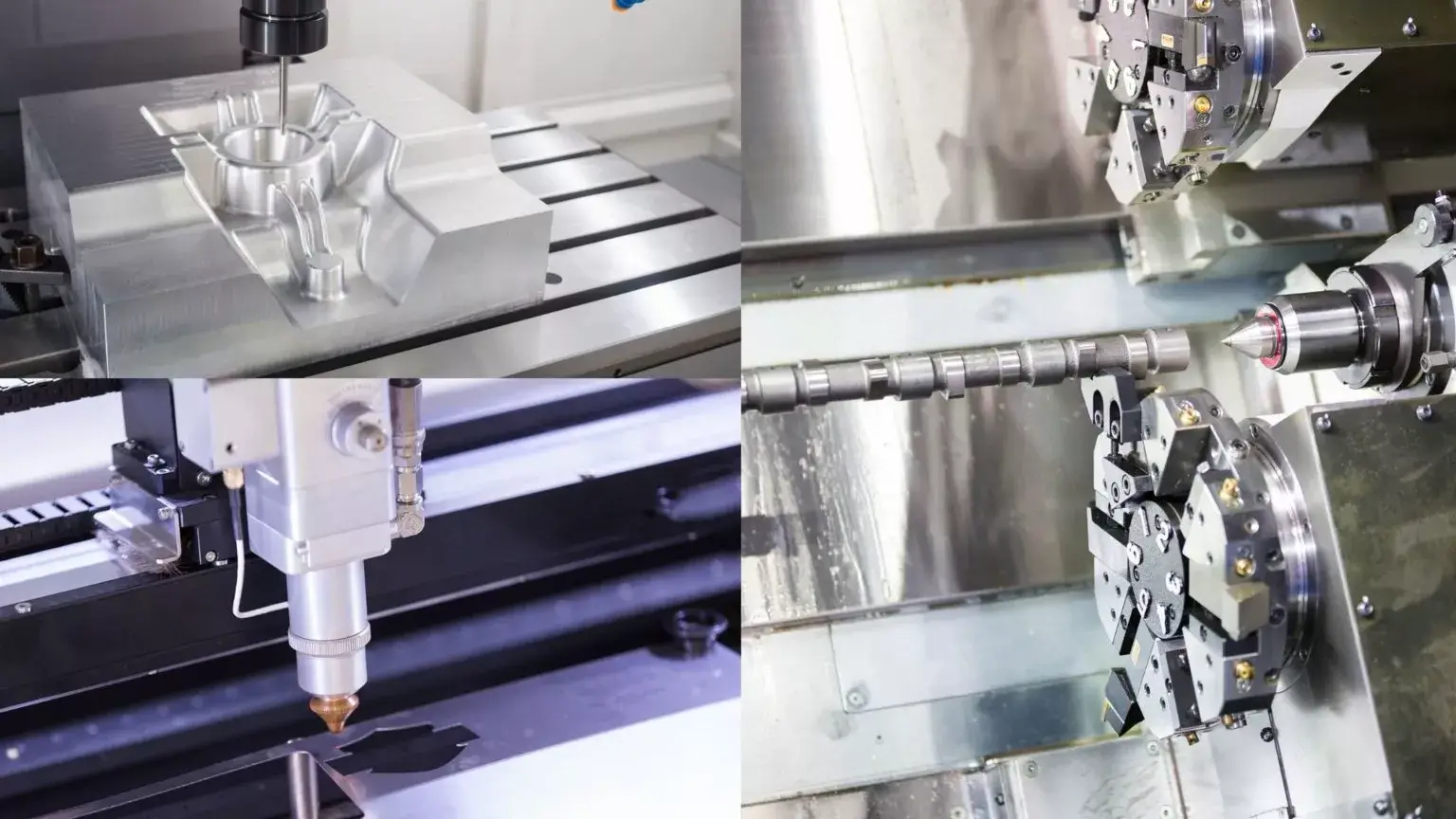

What are the Different Precision Machining Methods and Equipment?

There are many different machines and equipment for precision machining due to the wide applications of the process. Various parts require different types of cutting, so a range of cutting tools have been developed.

CNC Milling Machines

CNC milling is a subtractive manufacturing process that uses rotary cutters to remove material from the workpiece. The direction, angle, pressure, and cutting tool speed can vary to create different cutting effects. CNC mills come in many variants, such as bed, box, C-frame, floor, gantry, horizontal boring, knee, planer style, turret, and ram milling machines.

CNC Turning

In CNC turning, the workpiece rotates along a central axis, and a linearly moving cutting tool removes the material from the workpiece. The cutting tool is usually non-rotary, unlike CNC mills. Most commonly, single-point cutting tools are used in this process.

Precision Grinders

Precision grinders are one of the final manufacturing processes after machining parts/components. In precision grinding, abrasive grinders (or grinding wheels) create a perfectly flat surface with a very smooth finish on the machined parts. Additionally, precision grinding can help produce close-tolerance finishes on a finished product by removing small bits of excess material.

CNC Drill Presses

In CNC drill presses, the workpiece is held stationary while a rotating drill bit moves around and creates holes in the workpiece. The holes may be for parts assembly or aesthetic purposes. CNC drill presses can create different-sized holes by varying the size of the drill bit. The hole depth can be adjusted by controlling the machine tool calibration.

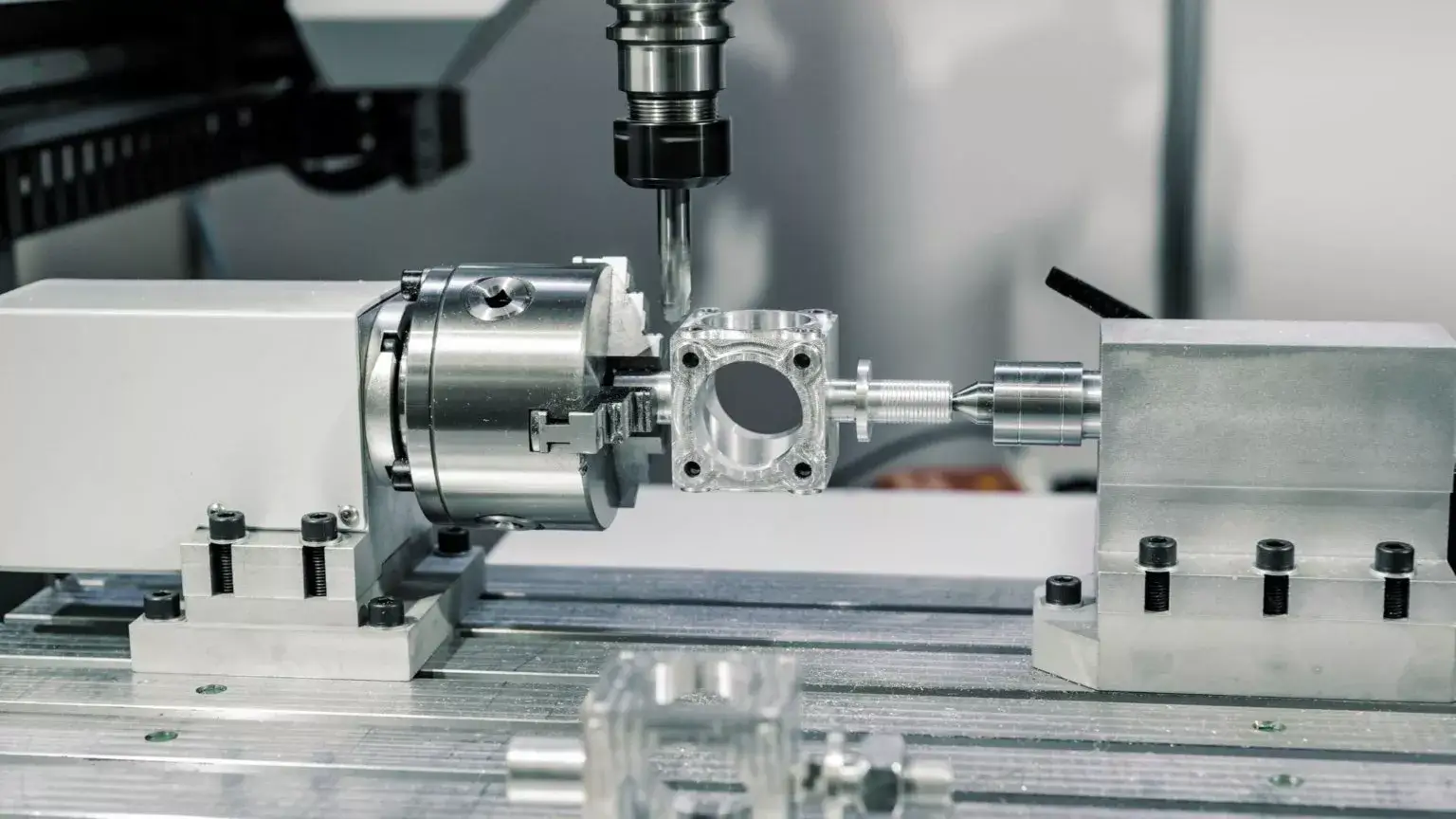

Multi-axis CNC Machining

Multi-axis CNC machining is an entire machining system. The cutting tool can move in four or more directions. Multi-axis CNC machining enables the creation of complex parts using various cutting tools and processes such as milling, waterjet cutting, or laser cutting.

Electrical Discharge Machining

In Electrical Discharge Machining (EDM), a metal is shaped with the help of electrical discharges (sparks). Other alternative names for this process are spark machining, die sinking, wire erosion, wire burning, or spark eroding. Electrical discharge machining only works on metals since they conduct electricity. It uses two electrodes – the tool electrode and the workpiece electrode. This machining method brings the two electrodes close to each other, but they do not make physical contact.

This creates an electrical arc between the electrodes, raising the temperature of the tool electrode and melting the metal. EDM applications usually involve the hardest metals due to the difficulty of machining them using milling machines. EDM is commonly applied to create holes, slots, and tapers in gears.

Swiss Machining

Swiss machining is an improvement on traditional lathes. It uses dedicated Swiss-made CNC lathes for cheap and precise machining of parts. In traditional lathes, the headstock is stationary and simply rotates the workpiece. However, in Swiss Machining, the headstock allows linear movement, providing more precise and complex machining options.

Apart from the moving headstock, a sliding guide bush moves along the longitudinal axis of the workpiece. The guide bush provides support to the workpiece for high-precision machining.

CNC Laser Machines

CNC laser machining employs a high-frequency laser beam to slice or engrave materials. Unlike EDM machining, laser machining can work for machining non-metals just as well as metals.

Mill Turning CNC Centers

CNC mill turning centers, or CNC mill-turn machines, combine milling and turning operations. Traditionally, milling and turning are done on separate CNC machines. However, incorporating them into a single machine can simplify the manufacturing process significantly. CNC mill-turn centers are available in two configurations – vertical and horizontal. The vertical configuration is considered more stable due to the effect of gravity on the setup.

What are the Benefits of CNC Precision Machining?

The cost of CNC precision machining can be a bit higher than for conventional machining methods. However, the benefits the process offers make it worth the extra investment. Below are some of those benefits:

Tight Tolerances

Tight tolerances are the primary reason to use CNC precision machining. Tolerance is also known as dimensional accuracy. It refers to the slight deviation in the size of a machined part from its CAD blueprints.

CNC precision machining uses specialized processes and cutting tools to reduce the tolerances to the minimum values possible. This leads to higher accuracy of the parts compared to the original blueprints.

What are precision machining tolerances?

There are four different types of machining tolerances in generally performed precision machining:

- Unilateral Tolerances: In this type of tolerance, variation in dimensions is permitted in a single direction. The tolerance limit can either be above or below the intended size.

- Bilateral Tolerances: In this type of tolerance, variation in dimensions is permitted in both directions. It is accepted for the tolerance limit to be both above or below the intended size.

- Compound Tolerances: Compound tolerance is the final tolerance calculated after adding or subtracting the tolerances of different dimensions that make up a part.

- Limit Dimensions: The upper and lower dimensional limit is defined instead of defining the required dimensional size. For instance, it is preset that the dimension can fall in the range of 20 mm to 22 mm.

High Accuracy

The tight tolerances directly infer that the final product created by precision machining will have high accuracy. Precision machining is generally performed for parts that require interworking with other parts and components. Therefore, high accuracy becomes essential for these particular parts to work flawlessly in later stages.

High Repeatability

The concept of repeatability is one of the important foundation stones for modern manufacturing industries. Every part manufactured by a process is intended to look like every other part for the end user. Any deviation from this reproduction is often considered a defect. Precision machining is appealing in this regard. With high precision CNC machining, every part is identical to the original with negligible deviations.

Low Production Costs

Due to the lack of deviations in precision machining, there are fewer defective productions. So the process leads to a lower rejection rate of parts. Therefore, the cost of materials is lower. Additionally, being an automated computer-aided manufacturing process results in reduced labor costs. The combined reduction in labor costs and material costs means that the production costs of CNC machining are lower than any alternatives.

Speed and Efficiency

Precision machining involves high-speed robotics that can create parts faster than manual manufacturing on conventional lathes. Additionally, the parts have high accuracy and close tolerance finishes, so there is no need for secondary processes. This leads to faster production times, increasing the workshop’s productivity and efficiency.

Safety

A CNC machine replaces human labor with computer numerical control systems and eliminates the human error risk factor involved in the cutting processes. Workers can be transferred to more skill-intensive roles such as CNC design operations.

Why do we need precision machining parts?

The ability to make precision machined parts is one of the major benefits of CNC machining. On the whole, simple machining operations can also be carried out using manual machining, i.e. with a skilled machinist manually moving the arm of the machine onto the workpiece in order to make cuts.

But very fine features and tight tolerances are harder to achieve manually, and this is where a computer-controlled system following a digital blueprint really comes into its own. Companies may want precision machining parts for virtually any reason. However, some of the more common motives are outlined here.

Assembly

The close tolerances offered by precision machining are crucial when components need to fit together into a larger assembly. If the dimensions stray too far from the design, these components may not connect properly, rendering them useless.

Even if the assembly can technically be achieved, the end-user or consumer will not want to see accidental gaps or overhangs where components are supposed to be flush.

Aesthetics

Precision may also be required for cosmetic or otherwise visible parts, where the absence or deformities or imperfections would not be acceptable. Some products may require standard machining for internal components and precision machining for outward-facing or surface components, where visible blemishes would diminish the visual quality of the product or lead to safety issues (with accidentally sharp edges, for example).

Added value

A simple motivation for precision machining is that high-quality parts manufactured to close tolerances can be sold on for higher prices. A high-value product such as a stereo system or smartphone can only command its high retail value if its individual components are made to a high standard — regardless of whether the precision leads to any kind of practical advantage.

When we don’t need precision machining?

Despite the many advantages of precision machining, companies should be cautious when specifying close tolerances.

While precision machining may be necessary for certain features and dimensions, it can be a significant waste of resources to demand precision machining when standard machining tolerances would suffice.

This is because a feature with a 0.01 mm tolerance may require a totally new machine setup compared to the same feature requiring a 0.05 mm tolerance, dramatically increasing labor costs.

If your request for quotation (RfQ) returns a higher estimate than you were expecting, try loosening tolerances for non-critical dimensions

What are the Applications of Precision Machining?

Precision machining forms the basis of many industries, whether for tooling or making the final product. Some of the applications of precision CNC machining are:

Prototypes

Precision machining is utilized for making prototypes for all industries. Prototypes require a highly accurate reproduction of an intended design to depict product features. Precision machining is the ideal way to fulfill these criteria.

Automobiles

Medical Industry

Medical technology is becoming more and more complex. There are automated tools and equipment in the medical industry that can even perform surgeries. This equipment requires intricate machining on a micro level, made possible by precision machining.

Aerospace

The aerospace industry utilizes some of the most advanced equipment, materials, and technology. It requires a machining process that is not only highly accurate but can also work on the hardest materials. Precision machining provides a simple solution to create all kinds of parts in the aerospace industry, from prototypes to full-scale parts.

Defense Industry

The defense industry has requirements similar to the aerospace industry. It calls for the most rugged materials requiring quality precision machining. The applications are wide and varied, from new weapons prototypes to entire missile systems.

Suitable Materials for Precise Machining

Precise machining works on hundreds of different metals, plastics, and other composite materials. Here is a list of some common materials that undergo precise machining:

Metals and Alloys

- Aluminum

- Bronze

- Brass

- Copper

- Titanium

- Steel

- Stainless Steel

- Carbon Steel

- Tool Steel

- Exotic Alloys

Plastics and Other Non-metals

- Polyamide (PA)

- Polycarbonate (PC)

- Acrylonitrile Butadiene Styrene (ABS)

- Polymethyl Methacrylate (PMMA)

- Polyoxymethylene (POM)

- Glass

- Graphite

What are the Typical Costs for Precision Machining?

Generally, there is no exact cost of precision machining because the costs can vary based on many factors. There are many different components of CNC machining, and these components have several cost options. For instance, there is a choice of the number of axes in precision machining equipment. A multi-axis machine can cost two to three times more than a 3-axis machine comparing hourly rates.

There are many other costs, such as the cost paid to the designer for the Computer Aided Manufacturing (CAM) blueprint, the hourly labor cost of a precision machinist based on the precision machinist’s skills, and more.

How to outsource precision machined parts?

Due to the skill level required to make precision machined parts, many companies will outsource their precision machining jobs even if they have CNC machining equipment of their own.

Outsourcing precision machining is a lot like ordering standard machined parts, with a few important differences.

Many machine shops will ask at the outset whether the customer requires precision machining, as this usually indicates that the RfQ requires extra consideration. If not, then the requirement for precision machining can be indicated simply by including tolerances.

Tolerances can be specified in a few different ways. One way is to indicate a general tolerance in the title block of a technical drawing. Another is to indicate tolerances on specific dimensions on the drawing.

Helpfully, many CAD applications also allow for tolerances to be included on the digital design. By indicating a tolerance closer than the standard (i.e. +/-0.05 mm), the machinist will know to consider this a precision machining operation.

Remember, however, that not all tolerances are formatted the same way. In fact, there are three common ways of specifying tolerance, which convey different instructions to the manufacturer. These are:

- Bilateral tolerances: States the acceptable tolerance either side of the specified value. Typically expressed as a +/- value, e.g. 22 mm +/-0.07 mm.

- Unilateral tolerances: States the acceptable tolerance on each side of the specified value. The tolerance on one side is sometimes zero, such as when a part must fit strictly within a hole. Typically expressed with the positive tolerance followed by the negative tolerance, e.g. 56 mm +0.5/-1.5 mm.

- Limit tolerances: States the acceptable tolerance as a range of acceptable dimensions. For example, a dimension of 7.5 mm with a bilateral tolerance of +/-0.5 mm would be written as 7–8 mm.

Budget Precision Machining With Best Value For Money

One of the best ways to minimize the cost while maintaining the highest quality precision machining is to outsource the process to 3ERP. 3ERP provides expert precision machining services with the option of 3-axis, 4-axis, and even 5-axis CNC machining parts. The manufacturing instructions are customized based on customer requirements.

At 3ERP, we receive many RfQs for precision machining projects. We understand how some parts require more care and attention than others, but we remain committed to offering a fair price even for close-tolerance machining.

One of the major benefits of outsourcing manufacturing to 3ERP is that the part is manufactured with the most high-end CNC precision machining equipment. Customers benefit from the features of this advanced equipment without any need to invest in initial purchasing costs.

There is even a dedicated Quality Check Department to ensure that every piece created by 3ERP has the highest quality standards.

Conclusion

It has become the must-have technology for complex CNC machining tasks that must work in tandem. When perfection is required at a microscopic level, every millimeter matters. The only way to achieve this perfection is through precision machining.

Precision machining is the best way to get the most value for money without compromising on dimensional accuracy. This is why the process has become the go-to manufacturing choice to make prototypes or produce parts on a large scale. If you need reliable precision machining services, get in touch with 3ERP, and you will receive a quote within 24 hours.

Frequently Asked Questions

Here are the answers to some common concerns that people have regarding precision machining:

1. What is the difference between precision machining and non-precision machining?

The major difference between precision and non-precision machining is that precision machining is designed for tight tolerances. It will produce parts that have greater accuracy, high repeatability, and lower defects.

2. What are precision machine parts?

Precision machine parts are created with specialized tools and equipment to meet the original design to the most accurate level. Precision CNC machining creates parts with the tightest tolerances. These parts can be made from metals, alloys, plastics, and other materials.

3. What are precision machine components?

Precision machine components are made with special tools and processes controlled with CNC technology. These processes commonly involve CNC machining mills, drills, turners, laser cutters, EDM cutters, and grinders.

4. What is high precision machining?

High precision machining, or high precision CNC machining, means using CNC machines to create parts with very high accuracy. The parts are designed based on Computer-Aided Design (CAD) blueprints.