Modern aluminum castings are ideal for wide-ranging applications due to their strength, durability, and cost-effectiveness.

Automotive Parts

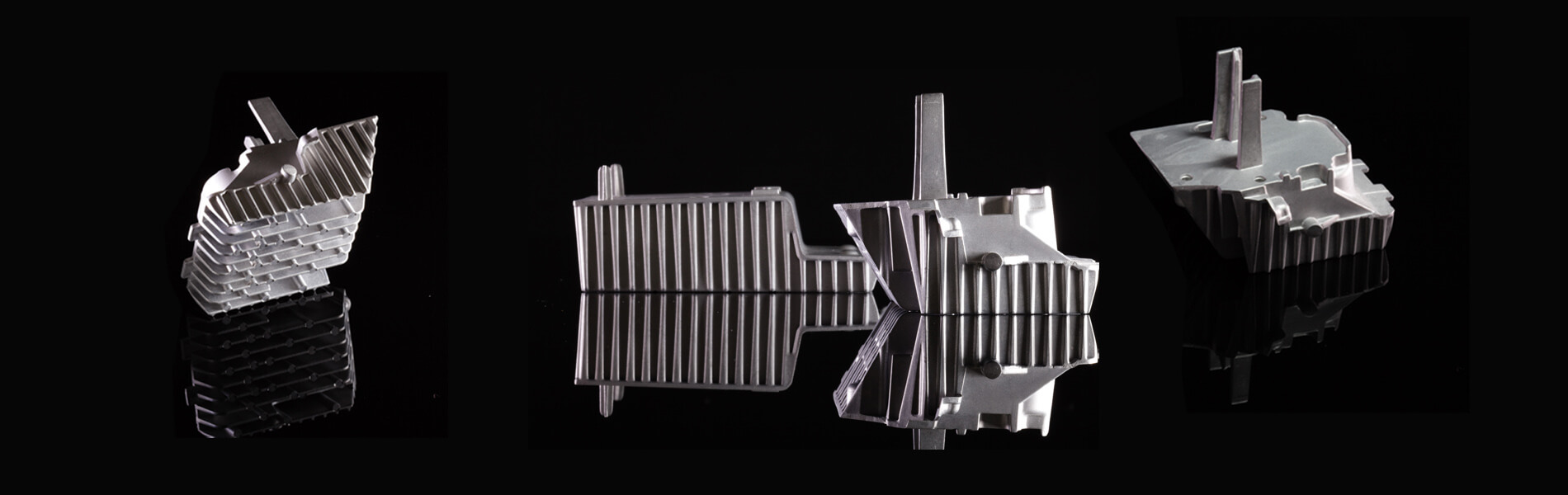

Aluminum castings are often used for automotive parts such as engine blocks, transmission cases, stators, auto forks, and heat sinks.

Aerospace Parts

Due to their high strength-to-weight ratio, aluminum castings are often used in the aerospace industry for parts such as fuselage frames and wing spars.

Machine Parts

Aluminum castings can create a variety of machine parts such as gears, pulleys, sprockets, pump covers, and brackets.

Electrical Components

Aluminum casting parts are non-magnetic and have good electrical conductivity. These characteristics make them ideal for electrical components such as switchgear housings, transformer cases, and junction boxes.

Consumer Products Contexts

In many consumer products, aluminum castings are used for their aesthetic appeal. Common examples include lawn furniture, decorative hardware, and architectural accents.

Recreational Equipment

Aluminum castings are often used in the production of recreational equipment such as boat hulls, snowmobile frames, and cosmetic components.