Rapid Manufacturing on Demand

1 to 1000+ Metal and Plastic Parts

Global delivery as fast as 10 days

Rapid Prototyping & Low-Volume Production

At 3E Rapid Prototyping, we are dedicated to making the world’s best prototypes and precision parts for a wide range of industries, including: automotive, medical device, aerospace, consumer & commercial products. Our experience in rapid prototyping & rapid manufacturing, such as CNC machining services and injection molding services enables us to make the most of both metal and plastic prototype for many different project types. And, we transform your ideas into a market-ready product with a super short turnaround, which helps launch your ideas fast. Find out what we can do for you!

Outsourcing Services

Due to our location and our experienced project management team, we can easily outsource many different manufacturing processes, for example investment casting and forging.

Why use us for outsourcing?

Since we have already done the audit process for these companies, we know which companies are the right ones for your projects. We always maintain proper quality control over outsourced projects to make sure your parts are exactly as you requested.

Manufacturing Services We are offering

Rapid Prototyping

- 3D Printing

- Plastic 3D Printing

- Metal 3D Printing

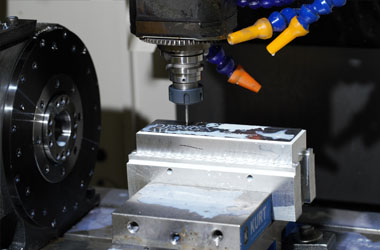

- Prototype CNC Machining

- CNC Milling

- CNC Turning

- Urethane Casting

- Sheet Metal Prototyping

Mass Production

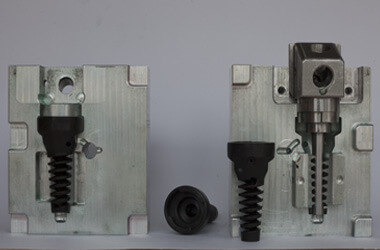

- Plastic Injection Molding

- Metal Injection Molding

- Sheet Metal Fabrication

- Pressure Die Casting