Metal casting, a metalworking process involving liquid metal and a mold, has existed for thousands of years.

Over its history, metal casting has been used to make everything from swords to wind turbines, and today it is one of the most valuable and versatile methods for making high-quality metal parts.

This guide looks at the basics of casting metal, including its many variants — die casting, investment casting, etc. — and the most common casting metals.

What is metal casting?

Metal casting is a manufacturing / fabrication process that involves pouring molten liquid metal into a mold.

The inside of the mold is designed with a negative impression of the part being made, so when the molten metal cools and solidifies within the mold, it takes the shape of the final part. The finished part can then be removed from the mold.

Depending on the parts being made and the metals being used, there are different varieties of metal casting, each with their own particular advantages. Patterns, molds, and filling techniques can vary greatly between these varieties.

Although casting metal is a versatile process, cast parts are subject to certain design constraints, and engineers must account for the shrinkage of metal during the cooling stage.

The metal casting process explained

The central metal casting process involves heating up a metal, pouring it into a mold, waiting for it to cool and solidify, then removing the finished part from the mold. In reality, there can be many more stages to the process, and different metal casting processes work in different ways.

The following is a simplified overview of the metal casting process. Note that some steps vary for different casting variants, while some are omitted altogether.

1. Making the pattern: Starting at the beginning, many metal casting processes require the fabrication of a pattern, a duplicate of the final part that is used to make the mold. Patterns can be either permanent or expendable, and can be made of materials like wax, wood, and plastic.

2. Making the core: For the casting of hollow parts, it may be necessary to design a core, a solid piece of material placed inside the mold cavity that shapes the interior geometry of a cast part. (For example, a cylindrical core within a larger cylindrical mold will produce a tube-shaped cast part.)

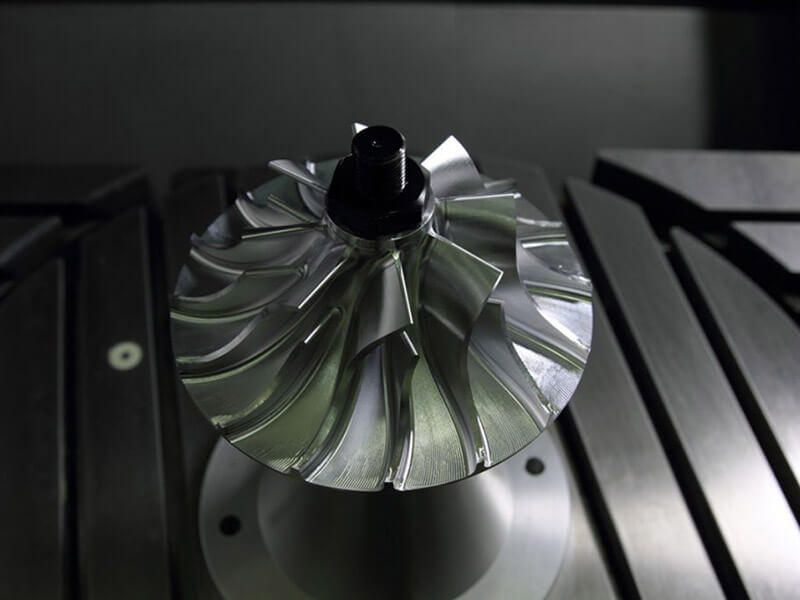

3. Making the mold: Molds are made in different ways depending on the process. For example, permanent metal molds can be made using a CNC machine, while sand molds are made by applying a sand mixture to the exterior of a pattern. The practice of fabricating molds is known as moldmaking and is a specialist discipline.

4. Filling the mold: The metal is heated up until it melts, then poured or forced into the mold. In gravity casting, for example, the molten material is poured downwards into the cavity; in high pressure die casting, it is forced into the cavity at high pressure, with high clamping forces required to keep the die secure.

5. Removing the part: Once the cast part is cooled and solidified, it is removed from the mold. For processes like sand casting, this means the mold must be destroyed to get to the part inside; for permanent molds, the two halves of the metal mold are pulled apart and ready to use again.

6. Post-processing: Cast metal parts may require cleaning — to remove remnants of the mold, for example — or other post-processing steps before they are ready for use.

Advantages of metal casting

There are numerous reasons to choose metal casting over other metalworking options like forging or CNC machining. Some of the key benefits of metal casting include:

- Suitable for mass production

- Can produce huge and heavy parts

- Can produce very thick-walled parts

- Suitable for large one-piece parts (rather than assembled components)

- Excellent bearing qualities

- Ideal for some light alloys

- Material versatility

Limitations of metal casting include unavoidable defects, limited dimensional accuracy (compared to e.g. CNC machining), labor-intensiveness, and typically high minimum order quantities.

The main types of metal casting

Die casting

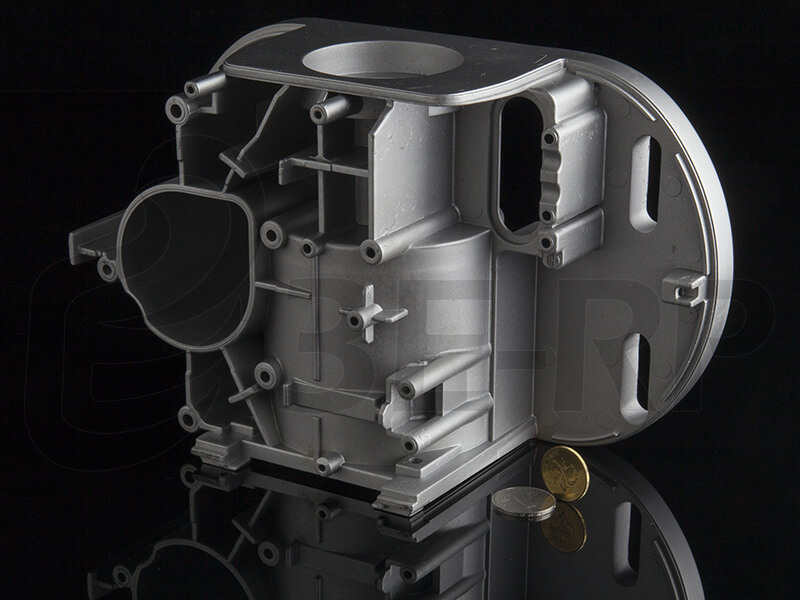

One of the most important types of metal casting for intricate and detailed parts, die casting uses two reusable tool steel dies as tooling. The process is similar to plastic injection molding: the molten material is forced into the cavity at high pressure, which allows engineers to make parts with fine details.

The cost of creating custom dies is high, which makes the process more common in mass production. Once manufactured, however, these dies can be used many times. Die castings tend to have an excellent surface finish.

Aluminum die casting and magnesium die casting are both widely employed for high-quality parts.

Gravity casting

Like die casting, gravity casting is a way of casting metal using a reusable metal mold. However, gravity casting relies upon gravitational forces to move liquid metal through the mold, top to bottom, rather than pressure. Molds must be preheated before the first casting and are often made from cast iron due to its low thermal fatigue.

Gravity casting predates all other metal casting techniques, with gravity cast parts existing for millennia. It is a form of permanent mold casting; alternatives to the gravity cast process include gas pressure and vacuum.

Investment casting (lost wax casting)

Investment casting or lost wax casting is a way of casting metal using an expendable pattern and mold: both items are destroyed during the casting process (although the melted wax can often be reused).

Like gravity casting, investment casting is thousands of years old. During the lost wax casting process, a pattern is made from wax or an equivalent material — sometimes by hand, sometimes using a resin 3D printer — before a refractory material is poured around the pattern to make the mold.

The investment is the ceramic layer applied around the pattern which then functions as the mold for the molten metal. This ceramic layer is removed in a process called divesting.

Sand casting

Sand casting is a simple, centuries-old method of casting metal and is more affordable than alternative techniques. It uses sand (mixed with a bonding material like clay) as a mold material, and the molds are capable of withstanding high heat.

In the sand casting process, a pattern is immersed in sand contained within a special box called a flask. By compacting the sand around the pattern, a mold can be made into which molten metal can be poured.

The sand used in the metal casting process can be either green sand (wet clay) or air set sand (dry sand with an adhesive).

Other casting processes

There are dozens more metal casting processes used in manufacturing, including loam molding and shell molding — both expendable mold processes — and permanent mold processes like centrifugal casting and continuous casting.

Casting pressure: high or low?

Metal die casting is a valuable metalworking process, and it can be divided into two further categories: high pressure die casting and low pressure die casting. Choosing the right pressure depends on factors like material, wall thickness, and part size.

High pressure die casting is a more common technique than low pressure die casting, and is used more than twice as often.

Ideal for soft alloys like aluminum and zinc, high pressure die casting involves forcing the liquid metal into the mold at high pressure and high speed, requiring a powerful press to keep the mold closed. The process is therefore more expensive than low pressure die casting.

Advantages of high pressure die casting:

- Fast production

- Thin walls possible

- Smooth surface finish

- Minimal shrinkage

Low pressure die casting is a slower form of die casting that forces molten metal into the mold more gently. It is suitable for alloys with low melting points. Although slower than high pressure die casting, the process of casting metal at low pressure is suitable for complex geometries and can produce very strong parts.

Advantages of low pressure die casting:

- Strong parts

- Complex geometries

Castable metals

A variety of metals are suited to the casting process. However, the three most common casting materials accepted by 3ERP are aluminum, zinc, and magnesium.

Aluminum casting

Casting aluminum is the most widespread means of forming aluminum. It is used to manufacture items like industrial and automotive parts such as transmissions and engines from alloys such as A380 and A383.

There are a few ways to perform aluminum casting. Aluminum die casting is excellent for high-volume production due to its speed and excellent surface finish; permanent mold casting is suitable for extra-strength aluminum parts; and sand casting is appropriate for the aluminum casting of small quantities and intricate geometries.

Regardless of the casting process, casting aluminum makes strong and lightweight parts and is therefore highly versatile.

Zinc casting

Zinc alloys are popular, affordable, and widely available metals suitable for casting. Zinc casting typically involves high pressure die casting, allowing for high production rates and minimal post-processing requirements.

Because of zinc’s high casting fluidity, zinc casting can result in parts with very thin walls and fine details. Zinc can also be cold-formed for better joining.

Manufacturers can choose between ZAMAK zinc alloys or zinc-aluminum (ZA) alloys. Cast zinc parts include automotive components, air conditioning parts, and electronic components.

Magnesium casting

Casting — in particular high pressure die casting — is by far the most common metalworking process for making magnesium parts, accounting for around 98% of magnesium part production.

As magnesium is the lightest of all structural metals, it is ideal for lightweighting applications. Other advantages of magnesium casting include very thin walls, excellent detail, and a good stiffness-to-weight ratio.

In small quantities, magnesium parts can also be made using plaster casting, though magnesium die casting is best for professional applications.

3ERP is a prototyping specialist with a dependable network of casting companies available for your next project, no matter how small. Get a free quote today.