3ERP’s polyurethane casting service lets you make small batches of plastic parts at a much lower cost than injection molding. These high-quality prototypes have a great surface finish and can provide a pathway to mass produced molded parts.

Many product designers are, however, unfamiliar with polyurethane casting, which requires a unique set of design considerations — both for the making of the master pattern and for the plastic castings themselves. Designing polyurethane cast parts is not the same as designing injection molded parts, so designers must familiarize themselves with the process before getting stuck into their CAD designs.

This article provides information on how to design polyurethane castings. It provides advice for feature design, looks at typical polyurethane casting tolerances, and notes the differences between polyurethane casting design and injection molding design.

What is polyurethane casting?

Otherwise known as vacuum casting, polyurethane casting is a prototyping and low-volume manufacturing technique suitable for creating batches of up to 25 units. It is the same as urethane casting, an alternate term for the process.

The polyurethane casting process comprises three main steps: making the master, making the silicone mold, and making the castings.

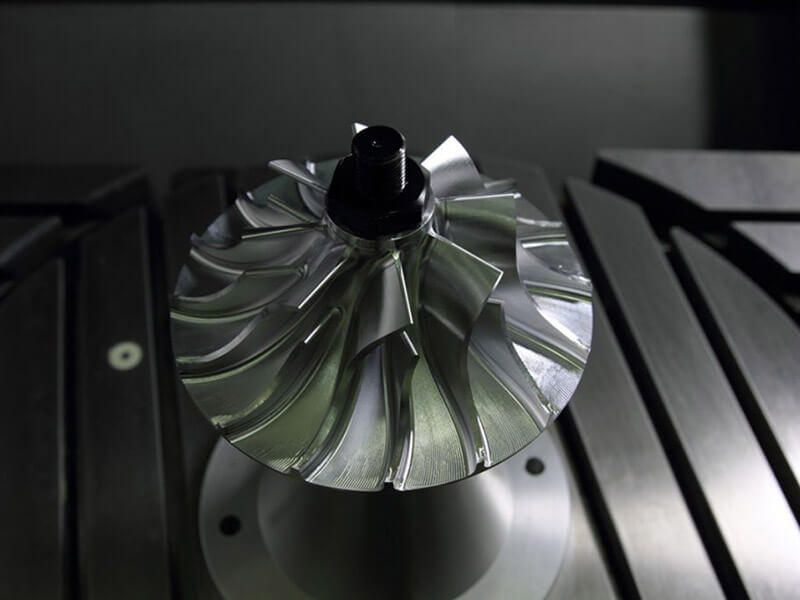

- Master: Using a process like CNC machining or SLA 3D printing, the designer creates a positive master pattern of the parts. Alternatively, a pre-existing part, made of virtually any solid material that can withstand temperatures of 40 °C (for the silicone curing stage), can be used as the pattern.

- Mold: A casting box is half-filled with liquid silicone with the pattern in the center. The silicone is cured at low heat in an oven for 16 hours until it becomes solid, making the first half of the mold. Then the rest of the casting box is filled with liquid silicone, which is cured to make the second half of the mold. The mold halves are removed and the pattern set aside for future use.

- Casting: The flexible silicone molds are filled with a polyurethane casting resin, which solidifies within the mold and assumes a solid shape identical to the original master. The silicone mold can be used around 25 times before it needs replacing.

Polyurethane casting is a valuable manufacturing technique because the silicone molds are incredibly inexpensive to make compared to metal tooling. They only last for around 25 castings, but this is usually sufficient for prototyping of small plastic parts.

Although casting polyurethane resins does not lead to strong functional parts, it does have unique strengths, such as producing an excellent surface finish, allowing for a range of colors and transparencies, and being highly economical in low volumes.

Making the master pattern

The first thing a product designer must consider during polyurethane casting design is the master pattern. Common techniques used to make casting patterns include 3D printing (SLA, PolyJet, etc.) and CNC machining. Traditional patternmaking techniques like manual sculpting can also be used, though this comes at a greater cost.

When using a digital manufacturing process like 3D printing or CNC machining, designers must effectively consider the design constraints of two separate processes at once: the patternmaking process and the casting, though this article will focus primarily on design tips that lead to effective casting (rather than effective 3D printing or CNC machining).

The advantages of 3D printing polyurethane master patterns are:

- Higher level of geometrical freedom

- Faster to make than CNC machining

The advantages of CNC machining master patterns are:

- Tighter tolerances than 3D printing

- Less surface finishing required

- Longer lifespan than 3D printed patterns

Tolerances & dimensions

When designing polyurethane cast parts, designers should be aware of standard tolerances and minimum/maximum dimensions, which are not the same as those for injection molding.

However, when using polyurethane casting as a prototyping technique for future injection molded parts, it might make sense to create a design that can also be injection molded (by incorporating draft angles etc.).

- Tolerance: 3ERP can make polyurethane parts to an accuracy of ± 0.3%, with a lower limit of ± 0.3 mm on dimensions smaller than 100 mm.

- Shrinkage: Thick parts are more susceptible to shrinkage, which occurs due to temperature shifts during the molding process. Designers should plan for a shrinkage rate of around +0.15%.

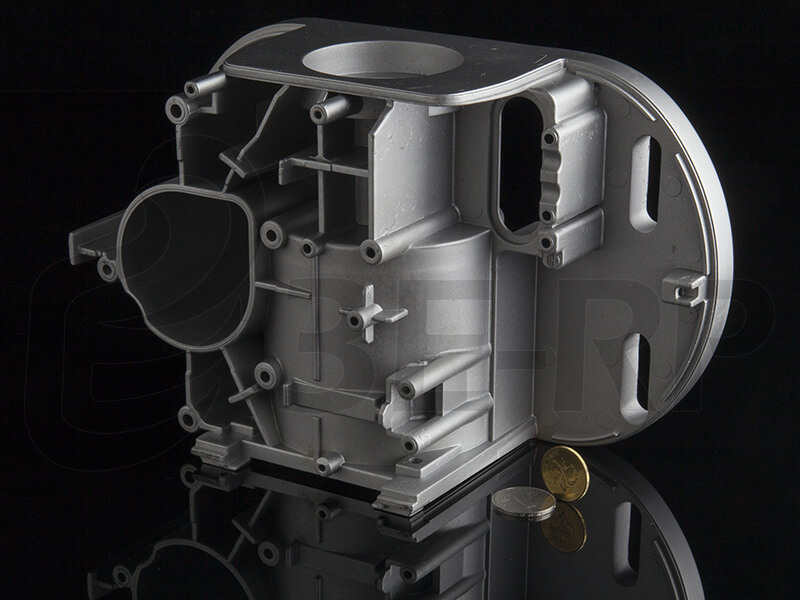

- Part size: Polyurethane cast parts can have dimensions of up to 1900 x 900 x 750 mm and a maximum volume of 10 liters.

Wall thickness

The polyurethane casting minimum wall thickness is 0.75 mm — adequate for proper mold filling, although 1.5+ mm will lead to the best results. If walls thinner than 0.75 mm are required, contact us to discuss your design.

As with injection molding, consistent wall thickness leads to better results, as it decreases the changes of temperature-induced deformation. However, varied wall thickness is less damaging than it is with injection molding.

Draft

One of the advantages of polyurethane casting is the flexibility of its silicone molds. Because the molds are flexible, the finished polyurethane parts can easily be removed from the mold without ejector pins. This also means that draft — tapered sides that allow for easy ejection — is not necessary like it is with injection molding.

That being said, a small draft angle of up to 5° can slightly prolong the lifespan of the silicone mold, so draft may be advantageous when carrying out medium-volume production runs on parts that do not require perfectly straight sides. This also makes the polyurethane casting design more adaptable to injection molding (for scaling up production).

Radii

When designing polyurethane parts, sharp inside corners should be avoided to maximize the strength and stability of the part. We recommend adding fillets to inside corners with a radius of 3 mm.

Note that using CNC machining to make the master pattern is ideal for adding fillets to polyurethane cast parts, because CNC cutting tools have a cylindrical shape and create natural rounded internal corners when cutting a pocket.

Ribs

To add stiffness to polyurethane casting parts without increasing wall thickness, designers can incorporate ribs, which increase the moment of inertia. Generally, it is better to use multiple short ribs than a single tall rib, and it is important to orient the ribs properly relative to where the part could potentially bend.

Ribs should have large corner radii and a thickness of less than 60% of the wall thickness to avoid shrinkage and sink marks. The height of each rib should be less than 3x its thickness to avoid breakage.

Bosses

Cast polyurethane parts can have bosses — small protrusions that accommodate fasteners or threaded inserts. These bosses can be supported by gussets or connecting ribs.

To prevent sink marks, the wall thickness of a boss should be less than 60% of the wall thickness of the part (as with ribs). The base radius of the boss should be at least 25% of the wall thickness of the part.

Threads & holes

Polyurethane casting can accommodate through holes and threads, and these are best achieved with the use of inserts rather than being added to the master pattern. However, these complex features can increase the cost of the project and may not be necessary for prototypes.

For through holes, dowel rods can be placed in the silicone mold. For threads, it is best to incorporate metal threaded inserts via insert molding.

Joints

Polyurethane casting can be used to make multi-components parts with tongue-and-groove joints. A small reveal gap should be incorporated into the joint between components.

Surface features

Surface features like text and logos can be incorporated into polyurethane cast parts. In general, these features — especially in recessed (engraved) form — are much easier to add using CNC machined master patterns than with 3D printed ones.

For best results, letters and numbers should be spaced at least 1.3 mm apart.

3ERP is a prototyping and low-volume manufacturing specialist which also functions as a polyurethane casting company. Contact us for a free quote.