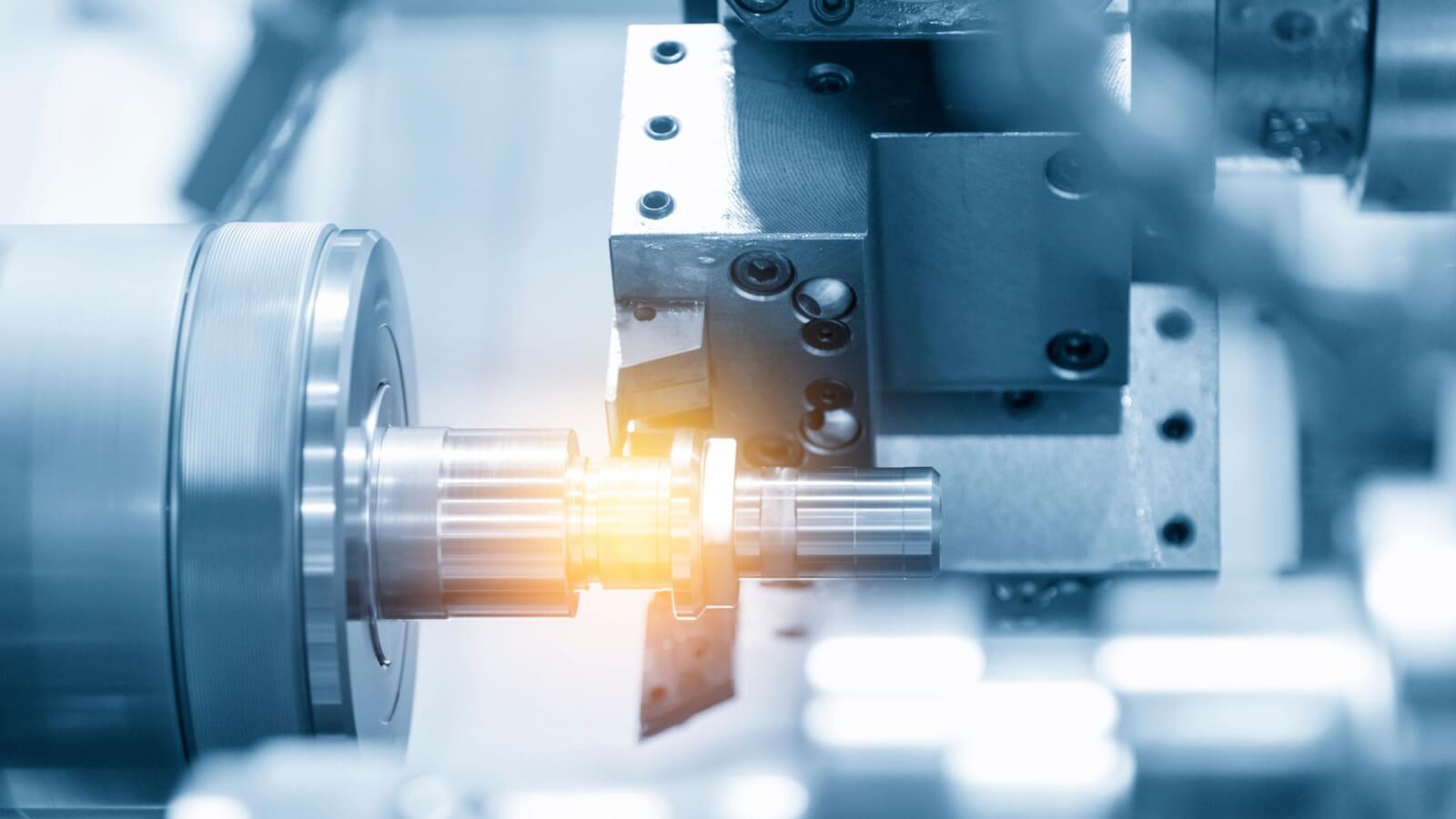

CNC Turning, or Computer Numerical Control Turning, is an important part of modern CNC machining processes and operations. This technology harnesses the precision of computer programming to manipulate lathe machines, transforming raw materials into meticulously crafted parts. CNC turning’s essence lies in its ability to produce cylindrical components with intricate details and high precision.

At its core, CNC turning involves a cutting tool moving linearly while the workpiece rotates, a dance of precision and control. This process ensures the creation of complex external and internal geometries, including tapers, threads, and slots.

Historical Development of CNC Turning

CNC turning has evolved significantly since its inception. This journey from manual lathes to advanced CNC machines highlights the relentless pursuit of accuracy and efficiency in the manufacturing industry.

The Evolutionary Path of CNC Turning Technology

From rudimentary lathes in the early 20th century to the first NC (Numerical Control) machines developed in the 1940s and 1950s, each step has been a leap towards greater precision and automation. The introduction of computers in the control process, hence the term CNC, marked a pivotal shift, bringing unparalleled accuracy and speed to turning operations.

How Does CNC Turning Work?

To comprehend the workings of CNC turning, one must understand its reliance on computer-generated programs. These programs dictate the movement of the machine’s tools, ensuring each cut is made with precision and consistency.

The Interplay of Machine and Program in CNC Turning

The CNC machine interprets a CAD (Computer-Aided Design) file, converting it into a set of precise instructions. These instructions guide the machine’s movements, determining the path, speed, and depth of the cutting tool.

What are Operations That Can Be Performed with CNC Turning?

CNC turning is not a one-trick pony; it’s a versatile process capable of executing various operations. Each operation caters to specific requirements, from basic shaping to complex detailing.

Turning Specific Operations (External)

Turning

Turning, the most fundamental of CNC operations, involves rotating a workpiece on a lathe while a cutting tool shapes it to the desired form. This process excels in producing cylindrical parts and is crucial in fabricating items such as shafts, pins, and rods. It’s marked by its ability to achieve high surface finishes and dimensional accuracy.

Hard Turning

Hard turning is a specialized operation that focuses on materials with high hardness ratings. This process often replaces grinding and involves cutting materials that are hard to shape. It’s known for its precision and ability to achieve fine finishes on tough materials, making it a go-to for components requiring high wear resistance.

Taper Turning

Taper turning is a technique used to produce conical shapes by gradually changing the diameter of the workpiece over its length. It’s essential for parts like cones and tapered shafts, offering a high degree of accuracy. This operation is critical for components that need to fit into specific angular spaces.

Facing

Facing involves removing material from the end of a workpiece to produce a flat surface. It’s often the first step in CNC turning operations and is crucial for preparing the ends of a piece for further machining. This process is vital for achieving precise face flatness and perpendicularity to the axis of the workpiece.

Grooving

Grooving in CNC turning is the process of cutting a groove into the surface of a workpiece. It’s commonly used for O-ring grooves, oil grooves, or where a specific recess is needed. The precision of CNC turning allows for exact groove dimensions, essential for parts requiring specific fits.

Parting

Parting, also known as cutoff, is the operation of cutting a workpiece through its diameter to separate it into two parts. This technique is used to create discrete components from a longer workpiece. It’s a critical step in the production of multiple parts from a single piece of material.

Non-Specific Operations (Internal)

Drilling

Drilling in CNC turning involves creating cylindrical holes in a workpiece. This operation is essential for parts requiring assembly, such as those needing bolts or pins. The precision of CNC machines ensures that these holes are drilled accurately, both in terms of diameter and depth.

Boring

Boring is used to enlarge pre-existing holes or to improve their dimensional accuracy and surface finish. This internal operation is crucial for parts that require precise hole dimensions or a specific internal surface finish. It’s particularly important for components where hole diameter plays a critical role in functionality.

Threading

Threading in CNC turning involves creating internal or external threads on a workpiece. This operation is fundamental for components that need to be assembled with screws or bolts. The precision of CNC turning ensures accurate thread pitch and depth, which are essential for the functionality of threaded joints.

Knurling

Knurling is the process of creating a patterned surface on a part to improve grip. This operation is commonly used on tool handles, knobs, and fasteners. CNC turning allows for precise control over the knurl pattern, ensuring consistent quality and the correct level of grip.

Reaming

Reaming is used to refine the size and finish of pre-drilled holes. This operation is crucial for achieving tight tolerances and smooth internal surfaces. It’s particularly important in high-precision industries, where the exact diameter and surface finish of holes can significantly impact the overall functionality of a part.

Each of these operations has specific applications and nuances, contributing to the versatility of CNC turning.

What are Different Types of CNC Turning Machines?

А CNC lathe is the most important components for the CNC turning process. The world of CNC turning machines is diverse, with each type tailored for specific needs. Understanding these differences is crucial for selecting the appropriate machine for a project.

Horizontal CNC Lathes

Horizontal CNC lathes, characterized by their horizontally aligned spindle, stand as a testament to the advancement in CNC technology and machining processes. These lathes are designed for optimum efficiency, facilitating a wide array of machining operations. With the integration of advanced computer numerical control systems, these machines offer precision and flexibility in machining various parts.

Applications:

- Aerospace Components: Crafting intricate components like turbine blades, engine mounts, and landing gear parts.

- Automotive Parts: Manufacturing engine components, gearboxes, and suspension systems.

- Electrical Fittings: Creating connectors, housings, and various electrical circuit components.

- Medical Equipment: Producing surgical tools, implants, and diagnostic devices.

- Consumer Electronics: Machining parts for smartphones, laptops, and other personal devices.

Advantages:

- High Precision: Achieving tight tolerances and intricate details with consistency.

- Versatility: Capable of machining a diverse range of materials, including metals, plastics, and composites.

- Large Volume Production: Ideal for high-volume manufacturing, ensuring speed and repeatability.

- Reduced Waste: Efficient material usage, minimizing scrap and optimizing raw material utilization.

- Customization Flexibility: Adaptable for bespoke manufacturing, catering to specific industry needs.

Typical Price Range: $30,000 – $150,000 USD

Vertical CNC Lathes

Vertical CNC lathes, distinguished by their vertically oriented spindle, are pivotal in machining heavy and large-diameter workpieces. These lathes offer a unique advantage in handling cumbersome materials, supported by their robust construction and advanced CNC control systems.

Applications:

- Large Gears and Flanges: Crafting components for industrial machinery and automotive applications.

- Heavy-duty Flywheels: Manufacturing essential parts for mechanical power transmission.

- Industrial Machinery Parts: Producing parts for manufacturing equipment, including presses and pumps.

- Wind Turbine Components: Machining large and heavy parts used in renewable energy sectors.

- Marine Equipment: Creating components for ship engines and propulsion systems.

Advantages:

- Heavy Part Handling: Specifically designed to manage heavy and large components.

- Operator Ergonomics: Reducing physical strain on operators, enhancing safety and comfort.

- Improved Chip Management: Effective removal of chips, maintaining clean operational conditions.

- Stability and Rigidity: Ensuring accuracy in machining, even with substantial workpieces.

- High Load Capacity: Capable of supporting and machining heavier materials efficiently.

Typical Price Range: $40,000 – $200,000 USD

Horizontal Turning Centers

Horizontal turning centers represent a leap in CNC machining, offering not just turning but also milling, drilling, and tapping capabilities. These centers embody the fusion of versatility and precision, making them ideal for complex parts production.

Applications:

- Multifaceted Industrial Components: Producing parts for industrial automation and robotics.

- Complex Mechanical Assemblies: Crafting components for aerospace and defense applications.

- Precision Tools: Manufacturing high-precision cutting tools and fixtures.

- Custom Automotive Parts: Creating bespoke components for specialized automotive applications.

- Energy Sector Components: Machining parts for oil and gas, and renewable energy industries.

Advantages:

- Multitasking Capabilities: Combining various machining processes in one setup.

- Reduced Setup Times: Minimizing downtime between operations, enhancing productivity.

- High Productivity: Efficiently producing complex parts with fewer machine setups.

- Flexibility in Design Changes: Adapting quickly to design modifications.

- Cost-Effectiveness: Reducing the need for multiple specialized machines.

Typical Price Range: $50,000 – $250,000 USD

Vertical Turning Centers

Vertical turning centers, akin to vertical lathes, elevate the CNC turning process by incorporating additional milling and drilling functions. These centers are tailored for intricate geometries and complex machining tasks, harnessing the power of CNC technology.

Applications:

- Precision Bearings: Manufacturing high-precision bearings for various industrial applications.

- Aerospace Engine Components: Producing critical parts for aircraft engines and systems.

- Complex Industrial Machinery: Crafting components for heavy machinery and equipment.

- Large-Scale Architectural Elements: Machining parts for structural and architectural applications.

- Research and Development Prototyping: Creating prototypes for experimental and innovative projects.

Advantages:

- Suitable for Complex Geometries: Excelling in producing parts with intricate designs.

- High Precision and Accuracy: Maintaining tight tolerances and high-quality finishes.

- Operator Visibility and Access: Facilitating easier inspection and maintenance.

- Enhanced Customization: Adaptable to a wide range of complex machining tasks.

- Reduced Floor Space Requirement: Optimizing workspace utilization with its vertical design.

Typical Price Range: $60,000 – $300,000 USD

What are common tooling types used in CNC turning?

Different tooling types are utilized to achieve various machining processes, each with its unique application and benefits. Here, we delve into some of the most common types of tooling used in CNC turning, highlighting their distinct features and applications.

- Turning Tools: These are the primary tools used for the CNC turning process. They are typically made of high-speed steel or carbide and come in various shapes and sizes to accommodate different turning operations like facing, threading, and grooving. Their primary application includes shaping the external surface of the workpiece to achieve the desired diameter and finish.

- Boring Bars: Used for enlarging and finishing an existing hole, boring bars are essential in achieving precise internal diameters and finishes. These tools are indispensable for operations requiring high accuracy and smooth internal surface finishes, such as in aerospace and automotive parts.

- Parting Blades: Employed to cut a part off from the rest of the workpiece, parting blades are designed to perform the parting or cutoff operation. They are crucial in the mass production of parts, allowing for efficient separation of components with minimal waste.

- Thread Cutting Tools: These tools are specifically designed for creating internal and external threads. With precision being key, thread cutting tools are vital for producing accurate and consistent threads, a necessity in parts requiring threaded joints like screws and bolts.

- Knurling Tools: Used to create a textured surface on a part, knurling tools are employed to enhance the grip on a machined component. They are commonly seen in tool handles, knobs, and decorative metal parts where a patterned surface is beneficial for grip or aesthetics.

- Drilling Bits: While not exclusive to turning, drilling bits in CNC lathes are utilized for creating cylindrical holes. These tools are indispensable in the production of parts that require assembly or fitting of components, ensuring precise hole dimensions and locations.

- Reamers: Reamers are used for refining drilled holes, ensuring the holes are of accurate size and have a smooth finish. This tooling type is essential in high-precision industries, where even minute discrepancies in hole dimensions can significantly affect the part’s functionality.

- Grooving Tools: Designed for cutting grooves into the surface of a part, grooving tools are essential for applications requiring specific recesses, such as O-ring grooves in seals or decorative grooving in aesthetic components.

- Face Mills: Although less common, face mills can be used in CNC turning for operations like facing large areas. They are particularly useful for ensuring a flat surface on the end of a large diameter workpiece.

- Turret Tooling: In CNC turning centers, turret tooling plays a significant role. It allows for multiple tools to be mounted and used in a single setup, enhancing the machine’s versatility and reducing setup times for complex operations.

What are Essential Components of a CNC Turning Machine?

A CNC turning machine, a marvel in the realm of precision machining, comprises various essential components, each integral to its efficient and accurate functioning. These components work in unison to transform raw materials into finished products with precision and intricacy.

- CNC Control Panel: The CNC control panel is the command center of the turning machine. It is where operators input and manage the machine’s computer programs, which guide the machining process. This panel enables the precise control of the machine’s movements, speed, and turning operations, ensuring accuracy and repeatability in the manufacturing process.

- Spindles: The spindle is a critical component that holds and rotates the workpiece or the cutting tool. In CNC turning, the spindle’s rotation speed can be precisely controlled, allowing for the machining of materials at the optimal cutting speed. This component is essential for ensuring the workpiece is machined accurately and to the desired specifications.

- Headstocks and Tailstocks: These components provide crucial support to the workpiece during the turning process. The headstock holds one end of the workpiece, while the tailstock can be moved and locked in position to accommodate various lengths of material. This setup ensures stability and precision in machining operations.

- Tool Turret: The tool turret is a revolving unit that holds multiple cutting tools. It allows for quick tool changes during the machining process, enhancing efficiency and productivity. The turret’s ability to hold various tools enables the machine to perform a wide range of operations like cutting, drilling, and threading without needing manual tool changes.

- Chuck and Collet: These components are used to hold the workpiece in place during the turning process. The chuck is a clamping device that can be adjusted to hold various sizes and shapes of materials, while collets provide a more precise and secure grip, especially for smaller or delicate workpieces.

- Lathe Bed: The lathe bed forms the base of the machine and is a foundation for the other components. It supports the headstock, tailstock, and carriage, ensuring alignment and smooth movement. The rigidity and construction of the lathe bed are crucial for maintaining precision during machining.

- Carriage: The carriage moves along the lathe bed, carrying the cutting tool. It consists of components like the saddle, cross-slide, and tool post, which together provide precise control over the tool’s movement and positioning. This component is vital for shaping the workpiece as per the programmed instructions.

What are The Main Parameters in CNC Turning?

In the realm of CNC turning, several parameters play a crucial role in determining the quality, efficiency, and outcome of the machining process. Understanding these parameters is essential for precision machining.

The Key Parameters of CNC Turning

- Cutting Speed: This is the speed at which the cutting tool engages the workpiece. It’s vital for determining the efficiency and quality of the cut.

- Feed Rate: Refers to the rate at which the workpiece is fed to the cutting tool, crucial for the control of material removal.

- Depth of Cut: This dictates how deep the cutting tool penetrates into the material, impacting the final shape and finish of the part.

- Tool Geometry: The shape and size of the cutting tool influence the type of cuts and the finish on the material.

- Material of the Workpiece: Different materials, from metals like steel and aluminum to plastics, require different turning parameters.

- Coolant Flow: The flow of coolant is essential for maintaining the temperature and ensuring the longevity of the cutting tool.

- Spindle Speed: This is the rotation speed of the spindle, which holds the workpiece or the tool, playing a key role in the turning operation.

- Tool Material: The material of the cutting tool determines its durability and suitability for different materials.

- Chip Control: Effective chip control is essential for maintaining the quality of the workpiece and the safety of the operation.

- Machine Rigidity: The rigidity of the CNC turning machine affects its ability to handle different materials and operations without distortion.

- Tolerance Levels: This refers to the degree of precision and accuracy that the CNC turning process can achieve.

Which Materials are Best Suited for CNC Turning?

Choosing the right material for CNC turning is pivotal in achieving desired results. The suitability of a material is influenced by its properties and the intended application of the finished part.

Common Materials Used in CNC Turning

- Steel: Known for its strength and durability, steel is commonly used in CNC turning for parts that require resilience.

- Aluminum: Lightweight yet strong, aluminum is preferred for parts that need to be both sturdy and light.

- Brass: With its low friction and non-sparking properties, brass is ideal for components in electrical applications.

- Copper: Highly conductive, copper is often used in electrical components.

- Plastics: Various plastics are used in CNC turning for their versatility and lower cost, suitable for a wide range of applications.

Each of these materials has its own set of properties that make them suitable for different types of CNC turning projects.

What are the Advantages and Disadvantages of CNC Turning?

Like any manufacturing process, CNC turning comes with its set of pros and cons. Understanding these helps in making informed decisions when choosing this process for manufacturing parts.

The Pros and Cons of CNC Turning

Advantages

- Precision and Accuracy: CNC turning provides exceptionally high precision, crucial for intricate parts.

- Efficiency: High-speed production capabilities make CNC turning a time-efficient process.

- Versatility: Ability to create a wide range of shapes and sizes from various materials.

- Repeatability: CNC turning ensures consistent quality across multiple production runs.

Disadvantages

- Initial Cost: The upfront cost of CNC machinery and setup can be high.

- Limitation on Shapes: While versatile, CNC turning is primarily used for round or cylindrical parts.

- Skill Requirement: Operating and programming CNC machines require skilled personnel.

How Do Precision and Accuracy Play a Role in CNC Turning?

In CNC turning, precision and accuracy are not just goals but necessities. The entire process hinges on the ability to produce parts that meet exact specifications and tolerances.

The Importance of Precision and Accuracy

Precision in CNC turning refers to the ability to achieve the desired dimensions and shapes consistently, while accuracy is about meeting the exact measurements specified in the design. These aspects are critical in industries where even the slightest deviation can lead to significant functional or safety issues.

What Industries Rely Heavily on CNC Turning?

CNC turning is a cornerstone in many industries, each with its specific requirements and applications.

Industries and Their Applications

- Automotive: Producing components like gears, shafts, and bushings.

- Aerospace: Fabrication of critical aircraft parts that require high precision.

- Electrical: Creating conductive components and connectors.

- Medical: Manufacturing surgical tools and implants with stringent quality standards.

Each industry leverages the capabilities of CNC turning to meet its unique production and quality demands.

What are the Key Design Considerations for CNC Turning?

In CNC turning, the design stage is critical for the success of the final product. Factors such as cutting speed, feed rate, and raw material choice play significant roles in determining the quality and efficiency of the CNC turning process.

Crucial Design Factors in CNC Turning

- Cutting Speed: This impacts the surface finish and tool life.

- Feed Rate: Essential for determining the rate of material removal and the final surface texture.

- Raw Material Choice: The material selected must be suitable for the desired end-use and compatible with CNC turning capabilities.

What Are the Basics of CNC Turning Programming and Software?

CNC turning is not just about the hardware; the software and programming behind it are equally vital. Understanding these basics is essential for anyone involved in CNC machining.

Overview of CNC Turning Programming

CNC programming involves creating a set of instructions that the CNC machine follows. This process starts with a CAD file, which is then converted into a CNC program using CAM (Computer-Aided Manufacturing) software.

Types of Software Used in CNC Turning

- CAD Software: Used for designing the parts.

- CAM Software: Converts CAD designs into machine-readable code.

- CNC Machine Control Software: Interprets the code and controls the machine.

Each software type plays a distinct role in the CNC turning process, ensuring precision and efficiency.

How Do CNC Turning and CNC Milling Compare?

CNC turning and CNC milling are two prominent methods in the manufacturing world. While they share similarities, their differences are critical in deciding which method to use for a specific project.

Workpiece Motion and Part Geometry

- CNC Turning: The workpiece rotates while the cutting tool moves linearly.

- CNC Milling: The cutting tool rotates while the workpiece is stationary or moves linearly.

Surface Finish, Tooling, and Setup Considerations

- Surface Finish: CNC turning generally provides a better surface finish for cylindrical parts.

- Tooling and Setup: Milling requires more complex tooling and setup compared to turning.

What Are Alternative Manufacturing Methods to CNC Turning?

While CNC turning is a popular choice, alternative methods also offer unique advantages and capabilities.

Comparing CNC Turning with Other Methods

- CNC Milling: Offers more versatility in part geometry but may require more complex setups.

- 3D Printing: Ideal for complex geometries and rapid prototyping but lacks the strength of CNC-turned parts.

Each manufacturing method has its niche, making them suitable for different applications.

How to Choose the Right CNC Turning Service?

Selecting the right CNC turning service provider is crucial for the success of your project.

Criteria for Selecting a CNC Turning Service

- Experience and Expertise: Look for a provider with a proven track record.

- Quality Assurance: Ensure they have strict quality control measures in place.

- Capacity and Capability: Verify that they can handle your project’s size and complexity.

- Turnaround Time: Consider their ability to meet your deadlines.

What are the Common Problems in CNC Turning?

Even with advanced technology, CNC turning can encounter several issues that need to be addressed promptly.

Common Issues in CNC Turning

- Tool Wear or Breakage: Affects precision and part quality.

- Surface Finish Issues: Can lead to rejection of parts.

- Dimensional Inaccuracies: Impact the usability of the part.

- Chatter and Vibrations: Affect the tool life and part quality.

- Material Deformation: Can occur due to improper tooling or settings.

- Chip Management Problems: Can lead to machine damage and quality issues.

- Programming Errors: Lead to incorrect machining and waste of materials.

- Coolant Issues: Affect tool life and part finish.

- Mechanical Failures: Can halt production and cause delays.

- Electrical Issues: Lead to downtime and potential damage.

- Operator Errors: Can cause accidents and quality problems.

What Are the Essential Safety Measures and Best Practices in CNC Turning?

Safety is paramount in CNC turning. Implementing best practices ensures the wellbeing of operators and the smooth functioning of the machinery.

Safety Measures and Best Practices

- Regular Maintenance: Essential for machine health and safety.

- Proper Training: Operators should be thoroughly trained in machine operation and safety protocols.

- Use of Protective Equipment: Essential to protect operators from injuries.

What Is the Environmental Impact and Role of Sustainability in CNC Turning?

The environmental aspect of CNC turning cannot be overlooked in today’s world, where sustainability is a growing concern. Understanding and mitigating the environmental impact is crucial for the future of CNC machining.

Sustainability in CNC Machining

- Resource Efficiency: CNC turning aims to maximize material utilization, reducing waste.

- Energy Consumption: Modern CNC machines are designed to be more energy-efficient.

- Recycling and Reusing Materials: Implementing practices to recycle metal shavings and reusing materials where possible.

- Eco-Friendly Coolants and Lubricants: Using environmentally safe substances in the machining process.

What Are the Cost and Economic Aspects of CNC Turning?

The financial implications of CNC turning are a major consideration for businesses. Analyzing costs and economic benefits helps in understanding the value of this technology.

Breaking Down the Costs

- Initial Investment: The purchase of CNC machines and software tools represents a significant upfront cost.

- Operational Expenses: Includes energy consumption, maintenance, and tooling costs.

- Labor Costs: Although CNC turning reduces labor costs, skilled operators and programmers are still needed.

Economic Benefits and ROI

- Efficiency Gains: CNC turning allows for faster production times, leading to higher throughput.

- Quality and Precision: High-quality parts reduce waste and improve customer satisfaction.

- Flexibility: Ability to quickly adapt to different designs and materials can open new market opportunities.

Conclusion

To sum up, CNC turning is an ever-evolving field, vital to numerous industries due to its precision, efficiency, and versatility. From its environmental impact to its economic implications, CNC turning continues to adapt and innovate, ensuring its relevance and utility in a rapidly changing technological landscape.

Discover unparalleled precision with 3ERP’s elite CNC turning services, a cornerstone in our array of CNC solutions. Our state-of-the-art facility is home to three advanced CNC lathes, each engineered to sculpt a diverse range of materials with unmatched accuracy.

From the robustness of metals like aluminum, magnesium, steel, stainless steel, brass, copper, bronze, titanium, and nickel alloy to the versatility of plastics including nylon, polycarbonate, ABS, POM, PP, PMMA, PTFE, PEI, and PEEK, our turning capabilities are vast.

3ERP is your go-to destination for both high-volume production and agile rapid prototyping, ensuring every project is a masterpiece of precision engineering.