In the world of machining, brass is one of the most versatile and sought-after materials for creating intricate and high-quality parts. This comprehensive guide will delve deep into the realm of brass CNC machining, exploring its advantages, brass grades and properties, tips for successful machining, available finishes, and factors to consider when choosing this process. Let’s dive in!

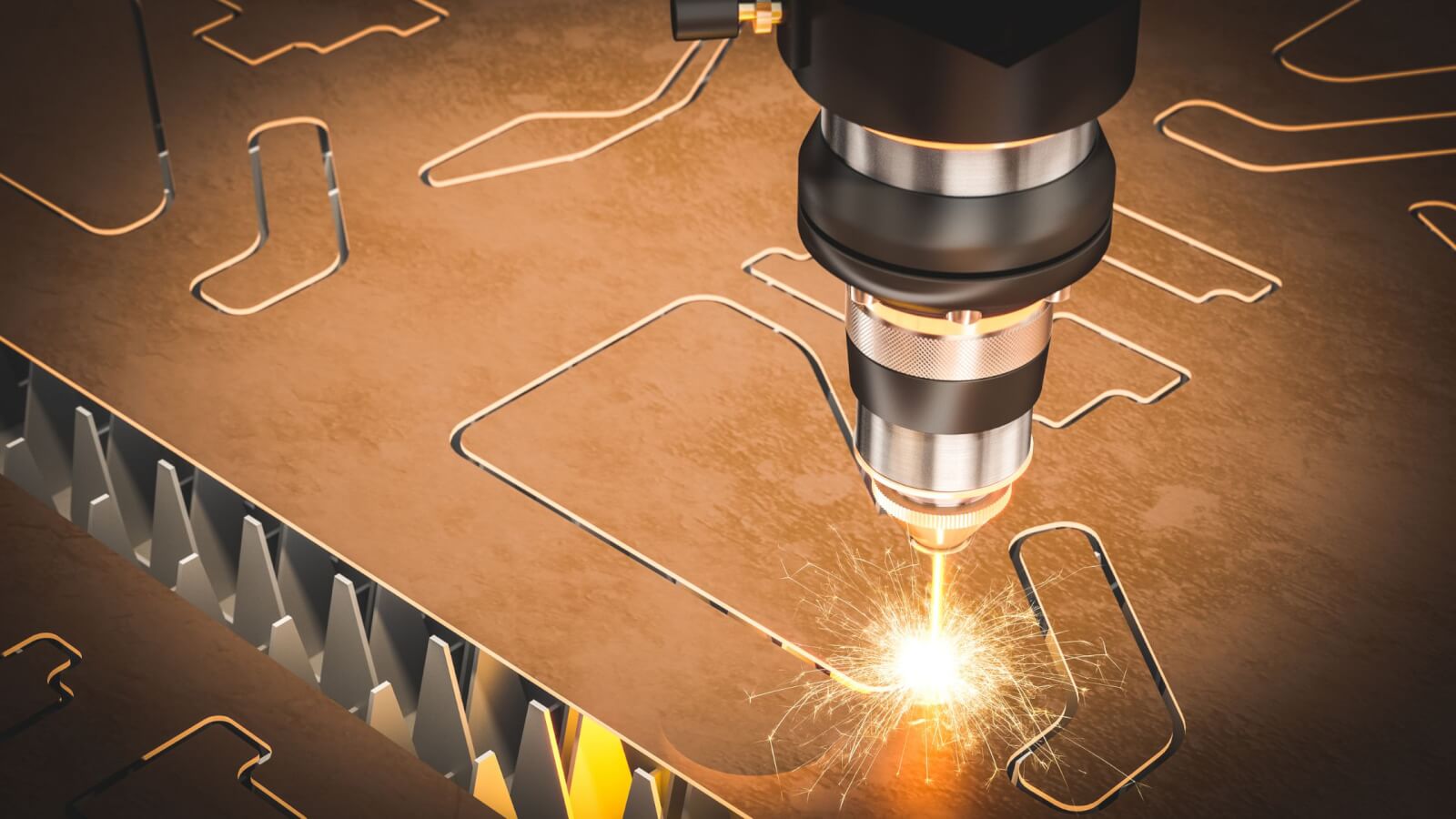

What is Brass CNC Machining?

Brass CNC machining is the automated process of cutting, shaping, and forming brass material using computer numerical control (CNC) machines. These machines are capable of working with extreme precision and accuracy, allowing for the production of intricate parts and components.

Brass, an alloy of copper and zinc, is one of the popular materials used for CNC machining due to its unique properties, which include excellent machinability, corrosion resistance, and electrical conductivity.

What are the Advantages of Using Brass for CNC Machining Projects?

Brass CNC machining offers a multitude of benefits over traditional manufacturing methods. Some of the most notable advantages include:

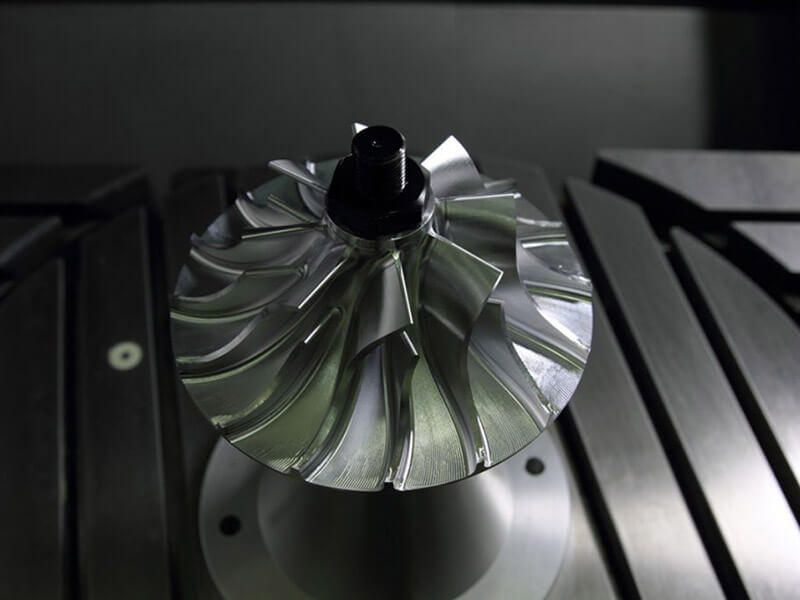

High Precision and Accuracy

CNC machines follow digital blueprints with great precision, ensuring that the final product is accurate and consistent.

Exceptional Machinability

Brass is known for its superb machinability, which enables complex parts to be manufactured with ease and precision. This quality translates to reduced machining time, longer tool life, and lower overall production costs.

Corrosion Resistance

Brass exhibits excellent corrosion resistance, especially in environments with high humidity or exposure to water. This property makes it an ideal choice for applications where durability and longevity are critical factors.

Versatility

The ability to customize the properties of brass by altering its composition allows for the creation of specialized alloys tailored to specific applications. This versatility makes brass an ideal candidate for a wide range of industries and purposes.

Cost-Effectiveness

Brass CNC machining can produce high-quality parts at a relatively low cost, making it an attractive option for businesses looking to minimize expenses.

Fast Production Times

With the aid of CNC machines, brass parts can be produced quickly and efficiently, allowing for shorter lead times and increased productivity.

Conductivity

Brass demonstrates good electrical and thermal conductivity, making it suitable for applications that require efficient heat or electricity transfer.

Aesthetic Appeal

With its golden hue and natural sheen, brass is a visually appealing material. Its aesthetic value adds to the desirability of brass components in applications where appearance matters, such as decorative elements or high-end products.

Brass Grades and Properties

Different grades of brass exhibit varying properties, making them suitable for specific applications. Some common brass grades used for machining and their properties include:

- C260 (Cartridge Brass): High ductility and strength, suitable for deep drawing and forming applications.

- C360 (Free-Cutting Brass): Excellent machinability and corrosion resistance, ideal for high-speed machining.

- C464 (Naval Brass): Superior corrosion resistance, especially in saltwater environments, making it ideal for marine applications.

Industries that Utilize Brass in CNC Machining

The unique properties of brass make it a preferred material for numerous industries. Some of the prominent sectors that employ brass in CNC machining include:

Plumbing and Heating

Due to its corrosion resistance and excellent heat transfer properties, brass is widely used in the manufacture of plumbing and heating components, such as valves, fittings, and fixtures.

Brass parts are known for their durability and ability to withstand harsh conditions, making them ideal for these applications.

Automotive Industry

The automotive industry utilizes brass in various components, including radiator cores, sensors, and electrical connectors. The alloy’s machinability and durability make it a suitable choice for parts that require precision and long-lasting performance.

Electrical and Electronics

Brass’s electrical conductivity, machinability, and corrosion resistance make it a popular material for manufacturing electrical components, such as connectors, switches, and terminals. Its aesthetic appeal also adds to the desirability of brass for high-end electronic devices.

Aerospace Industry

In the aerospace sector, brass is often used for manufacturing precision components like connectors, fittings, and fasteners. The alloy’s strength, machinability, and corrosion resistance are crucial for ensuring the reliability and longevity of aerospace parts.

Musical Instruments

The acoustic properties and visual appeal of brass make it a preferred material for manufacturing various musical instruments, such as trumpets, trombones, and saxophones. Brass components in these instruments contribute to their rich, resonant sound and elegant appearance.

Decorative and Architectural Elements

Brass’s aesthetic value and corrosion resistance make it an excellent choice for decorative and architectural applications. The material is commonly used to create fixtures, door handles, and other ornamental elements that add a touch of sophistication to buildings and interiors.

Marine Industry

The marine environment is particularly harsh on metals due to saltwater exposure, humidity, and temperature fluctuations. Brass’s corrosion resistance and strength make it a preferred choice for manufacturing marine components, such as propellers, fittings, and fasteners.

Our Tips for Successful Brass CNC Machining

To ensure the best results when machining brass, consider the following tips:

Choose the Right Brass Grade

Select a brass grade that matches the requirements of your project, taking into account factors like strength, ductility, and corrosion resistance.

Optimize Tooling and Cutting Parameters

Use sharp tools and appropriate cutting speeds and feeds to minimize tool wear and achieve a high-quality surface finish.

Manage Heat Generation

Implement proper cooling techniques to prevent overheating, which can cause material deformation and negatively impact the final product.

Brass CNC Machining Finishes

Brass CNC machined parts can be finished in various ways to improve their appearance, corrosion resistance, or durability. Some popular brass finishing options include:

- Polishing: Creates a smooth, reflective surface and enhances the part’s aesthetic appeal.

- Plating: Adds a thin layer of metal, such as nickel or chrome, to the surface, improving corrosion resistance and durability.

- Powder Coating: Applies a protective, colored coating to the part, increasing its resistance to wear, corrosion, and impact.

Factors to Consider When Choosing Brass CNC Machining

When selecting brass CNC machining for your project, consider these factors to ensure the best results:

- Material properties: Evaluate the properties of the chosen brass grade and ensure it aligns with the requirements of your application.

- Production volume: CNC machining is suitable for both low and high-volume production runs, but consider the cost implications and determine the most cost-effective method for your specific needs.

- Tolerances and dimensions: Brass CNC machining can achieve tight tolerances, but always verify that the machine’s capabilities align with the desired part specifications.

- Design complexity: CNC machining excels at producing intricate parts and designs; however, consider any limitations that may impact the manufacturability of your design.

- Lead time: Assess the required lead time for your project, taking into account factors like material availability, tooling, and production capacity.

3ERP offers top-quality CNC brass machining services, utilizing different brass alloys to create precise and accurate parts and components. With our advanced CNC machine centers and expert technicians, 3ERP can manufacture custom brass parts with exceptional accuracy to meet clients’ specific requirements. Contact us today for a free quote.

Conclusion

Brass CNC machining is a highly versatile and efficient manufacturing method that offers numerous benefits, including high precision, accuracy, and cost-effectiveness. By understanding the different brass grades and their properties, optimizing the machining process, selecting appropriate finishes, and considering essential factors, you can ensure the success of your machining project.

With the right planning and execution, brass machining can provide high-quality parts for a wide range of applications, making it an indispensable tool in modern manufacturing.