CNC machining has revolutionized the world of manufacturing, offering unparalleled precision and efficiency. One material that has stood the test of time in this field is brass, an alloy of copper and zinc.

With its excellent machinability and unique properties, it’s no wonder that brass is a popular choice for numerous applications. In this comprehensive guide, we will explore the various brass grades suitable for CNC machining and dive into their unique characteristics and applications.

Defining CNC Machining and Brass Grades

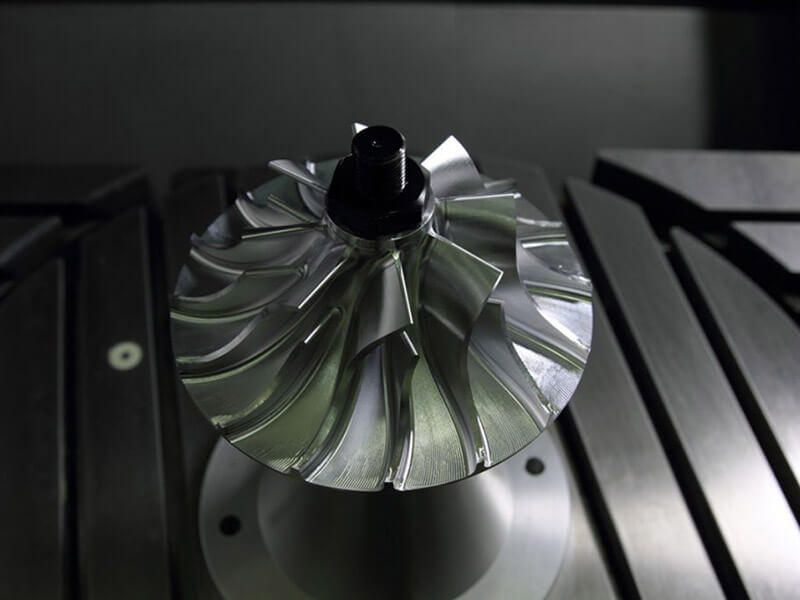

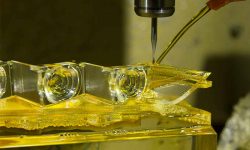

Brass machining is a manufacturing process that involves the use of computer numerical control (CNC) machines to cut, shape, and manipulate brass, which is a metal alloy primarily composed of copper and zinc.

In brass CNC machining, a design is first created using computer-aided design (CAD) software. The design is then converted into numerical code or G-code, which the CNC machine can understand. The CNC machine interprets this code to perform the necessary operations, such as drilling, milling, turning, or cutting, to create the desired brass component.

What are The Different Types of Machinable Brass?

Various brass grades have been developed to cater to different applications and requirements in CNC machining. These grades are identified by their copper and zinc content, as well as other alloying elements present.

C200 – C20000 Brass Grades

The C200 series, also known as the alpha brasses, contain a high copper content ranging from 95% to 99%. These alloys are known for their excellent corrosion resistance, making them a popular choice for plumbing fixtures and fittings, as well as electrical and electronic components.

Advantages:

- Corrosion Resistance: C200 brass grades exhibit exceptional corrosion resistance due to their high copper content. This characteristic makes them ideal for use in environments where they are exposed to moisture, chemicals, or other corrosive substances, ensuring durability and a long service life.

- Electrical Conductivity: The high copper content in C200 brass grades also results in excellent electrical conductivity. As a result, these alloys are often used in electrical and electronic applications, such as connectors, terminals, and wiring components.

- Ductility and Formability: C200 brass grades possess good ductility and formability, allowing them to be easily shaped and formed into various components. This property is particularly beneficial for applications that require intricate designs and complex geometries.

Common Applications:

- Plumbing fittings and fixtures: C200 brass grades are often used in the production of faucets, valves, and other plumbing components due to their corrosion resistance and durability.

- Electrical and electronic components: The excellent electrical conductivity of C200 brass grades makes them suitable for use in connectors, terminals, and other electrical components.

- Radiator cores: C200 brass grades are commonly used in the manufacturing of radiator cores for automotive and industrial applications, owing to their good heat transfer properties and corrosion resistance.

- Coins and medals: The attractive appearance and resistance to wear make C200 brass grades an ideal choice for minting coins and crafting medals.

- Decorative and ornamental applications, including plaques, medals, and sculptures

- Architectural applications, such as trim, moldings, cornices, window frames and hardware

- Fire sprinkler systems, Heat exchanger tubes and components

Main Disadvantages:

- Machinability: The high copper content in C200 brass grades can make them more difficult to machine compared to other brass alloys with lower copper content. This may limit their use in certain applications where intricate shapes and complex geometries are required.

- Cost: Due to the high copper content, C200 brass grades can be more expensive than other brass alloys with lower copper content

C210

C210 Brass Grade, also known as Gilding Metal or C21000 Brass, is a copper-zinc alloy known for its deep red color, ductility, and ease of cold working. This alloy consists primarily of copper (95%) and zinc (5%), which makes it an ideal choice for applications that require excellent formability and a rich, reddish hue.

Chemical Properties:

- Copper (Cu): 95%

- Zinc (Zn): 5%

- Other trace elements: Lead (Pb), Iron (Fe), Aluminum (Al), Silicon (Si), and Nickel (Ni)

Physical Properties:

- Density: 8.90 g/cm³

- Melting Point: 925-960°C (1700-1760°F)

- Tensile Strength: 280-455 MPa (40,600-66,000 psi)

- Yield Strength: 70-340 MPa (10,150-49,300 psi)

- Elongation: 30-60%

- Hardness (Brinell): 60-130 BHN

- Electrical Conductivity: 37% IACS (International Annealed Copper Standard)

C220

C220 Brass Grade, also known as Commercial Bronze or C22000 Brass, is a copper-zinc alloy characterized by its excellent ductility, strength, and corrosion resistance. This alloy is primarily composed of copper (90%) and zinc (10%), making it an ideal choice for various applications requiring a combination of formability and moderate strength.

Chemical Properties:

- Copper (Cu): 90%

- Zinc (Zn): 10%

- Other trace elements: Lead (Pb), Iron (Fe), Aluminum (Al), Silicon (Si), and Nickel (Ni)

Physical Properties:

- Density: 8.80 g/cm³

- Melting Point: 920-950°C (1690-1740°F)

- Tensile Strength: 315-520 MPa (45,700-75,400 psi)

- Yield Strength: 100-345 MPa (14,500-50,000 psi)

- Elongation: 25-55%

- Hardness (Brinell): 70-150 BHN

- Electrical Conductivity: 34% IACS (International Annealed Copper Standard)

C230

Brass Grade, also known as Red Brass or C23000 Brass, is a copper-zinc alloy known for its high corrosion resistance and excellent formability. This alloy primarily consists of copper (85%) and zinc (15%), which provides a unique combination of strength, ductility, and resistance to various types of corrosion.

Chemical Properties:

- Copper (Cu): 85%

- Zinc (Zn): 15%

- Other trace elements: Lead (Pb), Iron (Fe), Aluminum (Al), Silicon (Si), and Nickel (Ni)

Physical Properties:

- Density: 8.71 g/cm³

- Melting Point: 915-940°C (1680-1725°F)

- Tensile Strength: 300-550 MPa (43,500-79,800 psi)

- Yield Strength: 70-310 MPa (10,150-45,000 psi)

- Elongation: 20-60%

- Hardness (Brinell): 60-140 BHN

- Electrical Conductivity: 28% IACS (International Annealed Copper Standard)

C260

C260 Brass Grade, also known as Cartridge Brass or C26000 Brass, is a copper-zinc alloy known for its excellent ductility, strength, and corrosion resistance. This alloy primarily consists of copper (70%) and zinc (30%), offering a balanced combination of formability, strength, and a golden yellow color.

Chemical Properties:

- Copper (Cu): 70%

- Zinc (Zn): 30%

- Other trace elements: Lead (Pb), Iron (Fe), Aluminum (Al), Silicon (Si), and Nickel (Ni)

Physical Properties:

- Density: 8.53 g/cm³

- Melting Point: 930-965°C (1710-1770°F)

- Tensile Strength: 310-620 MPa (45,000-90,000 psi)

- Yield Strength: 90-370 MPa (13,000-53,700 psi)

- Elongation: 15-45%

- Hardness (Brinell): 80-160 BHN

- Electrical Conductivity: 28% IACS (International Annealed Copper Standard)

C272

C272 Brass Grade, also known as Yellow Brass or C27200 Brass, is a copper-zinc alloy recognized for its good ductility, strength, and corrosion resistance. This alloy mainly consists of copper (63%) and zinc (37%), which provides a desirable combination of formability, strength, and a yellowish-gold color.

Chemical Properties:

- Copper (Cu): 63%

- Zinc (Zn): 37%

- Other trace elements: Lead (Pb), Iron (Fe), Aluminum (Al), Silicon (Si), and Nickel (Ni)

Physical Properties:

- Density: 8.48 g/cm³

- Melting Point: 905-935°C (1660-1715°F)

- Tensile Strength: 315-585 MPa (45,700-84,800 psi)

- Yield Strength: 100-360 MPa (14,500-52,200 psi)

- Elongation: 15-45%

- Hardness (Brinell): 90-165 BHN

- Electrical Conductivity: 28% IACS (International Annealed Copper Standard)

C274

C274 Brass Grade, also known as Yellow Brass or C27400 Brass, is a copper-zinc alloy appreciated for its excellent ductility, moderate strength, and corrosion resistance. This alloy primarily consists of copper (62%) and zinc (38%), offering a balanced combination of formability, strength, and a golden-yellow color.

Chemical Properties:

- Copper (Cu): 62%

- Zinc (Zn): 38%

- Other trace elements: Lead (Pb), Iron (Fe), Aluminum (Al), Silicon (Si), and Nickel (Ni)

Physical Properties:

- Density: 8.47 g/cm³

- Melting Point: 900-940°C (1650-1725°F)

- Tensile Strength: 310-575 MPa (45,000-83,400 psi)

- Yield Strength: 90-355 MPa (13,050-51,500 psi)

- Elongation: 20-45%

- Hardness (Brinell): 85-160 BHN

- Electrical Conductivity: 27% IACS (International Annealed Copper Standard)

C300 – C30000 Brass Grades

The C300 to C30000 brass grades, also known as intermediate brasses or alpha-beta brasses, are characterized by a balance of copper and zinc content, providing them with a unique set of attributes that cater to various applications across different industries.

Advantages:

- Strength and Ductility: C300 to C30000 brass grades offer a balance between strength and ductility, making them suitable for applications that require both robustness and the ability to be easily shaped and formed. These alloys provide a compromise between the strength of beta brasses and the ductility of alpha brasses.

- Corrosion Resistance: Similar to alpha and beta brasses, C300 brass grades exhibit good corrosion resistance due to their copper content. This characteristic makes them suitable for use in environments where they are exposed to moisture, chemicals, or other corrosive substances, ensuring durability and a long service life.

- Machinability: Intermediate brasses generally offer good machinability. This property enables them to be easily shaped, cut, and formed into various components, making them a popular choice for machining applications.

Common Applications:

- Fasteners: screws, nuts, bolts, and washers

- Plumbing fittings: valves, faucets, and pipe fittings

- Automotive components: radiators, fuel tanks, and transmission parts

- Electrical connectors and components: terminals, switches, and plugs

- Marine hardware: propellers, boat fittings, and pump components

- Ammunitions: casings and cartridge components

- Gears and bearings: for machinery and equipment

- Architectural elements: decorative hardware, door handles, and window fittings

- Musical instruments: bells, cymbals, and brass instrument components

- Locks and padlocks: for security and durability

- Industrial machinery components: bushings, gears, and wear plates

- Consumer goods: zippers, buttons, and belt buckles

- Art and sculpture: castings and decorative elements

- Molding and extrusion: for complex shapes and profiles

- Coinage: due to its corrosion resistance and durability

Disadvantages

- Cost: The increased zinc content in C300 to C30000 brass grades may lead to higher production costs compared to alpha brasses with lower zinc content.

- Not as strong as beta brasses: While C300 grades provide a balance between strength and ductility, they may not be as strong as beta brasses, which could be a disadvantage in some applications where higher strength is required.

C360

C360 Brass Grade, also known as Free-Machining Brass or Free-Cutting Brass, is a high-grade copper-zinc alloy with excellent machinability. This alloy is composed primarily of copper (61%), zinc (35%), and lead (3%). The addition of lead results in improved machinability, which makes it ideal for producing intricate and complex parts through machining processes.

Chemical Properties:

- Copper (Cu): 61%

- Zinc (Zn): 35%

- Lead (Pb): 3%

- Other trace elements: Iron (Fe), Aluminum (Al), Silicon (Si), and Nickel (Ni)

Physical Properties:

- Density: 8.47 g/cm³

- Melting Point: 930-935°C (1710-1715°F)

- Tensile Strength: 370-470 MPa (53,700-68,100 psi)

- Yield Strength: 210-320 MPa (30,500-46,400 psi)

- Elongation: 12-25%

- Hardness (Brinell): 100-160 BHN

- Electrical Conductivity: 26% IACS (International Annealed Copper Standard)

C314

C314 Brass Grade, commonly referred to as Leaded Commercial Bronze or C31400 Brass, is an alloy of copper, zinc, and lead. Renowned for its remarkable machinability, this alloy exhibits a blend of copper (89%), zinc (9%), and lead (2%), making it suitable for a range of applications that require easy machining, fair strength, and corrosion resistance.

Chemical Properties:

- Copper (Cu): 89%

- Zinc (Zn): 9%

- Lead (Pb): 2%

- Minor traces of elements: Iron (Fe), Aluminum (Al), Silicon (Si), and Nickel (Ni)

Physical Properties:

- Density: 8.77 g/cm³

- Melting Point Range: 910-945°C (1670-1735°F)

- Tensile Strength: 295-515 MPa (42,800-74,700 psi)

- Yield Strength: 80-325 MPa (11,600-47,100 psi)

- Elongation: 20-60%

- Hardness (Brinell): 65-140 BHN

- Electrical Conductivity: 33% IACS (International Annealed Copper Standard)

C330

C330 Brass Grade, often referred to as Low-Leaded Brass or C33000 Brass, is an alloy composed of copper, zinc, and a small amount of lead. This alloy is valued for its good machinability, ductility, and moderate strength. The primary constituents of C330 are copper (65%), zinc (34%), and lead (1%), which make it suitable for various applications that demand easy machining and fair strength.

Chemical Properties:

- Copper (Cu): 65%

- Zinc (Zn): 34%

- Lead (Pb): 1%

- Minute traces of elements: Iron (Fe), Aluminum (Al), Silicon (Si), and Nickel (Ni)

Physical Properties:

- Density: 8.49 g/cm³

- Melting Point Range: 900-950°C (1650-1740°F)

- Tensile Strength: 300-570 MPa (43,500-82,700 psi)

- Yield Strength: 90-350 MPa (13,050-50,750 psi)

- Elongation: 10-50%

- Hardness (Brinell): 75-160 BHN

- Electrical Conductivity: 27% IACS (International Annealed Copper Standard)

C335

C335 Brass Grade, commonly known as Free-Machining Brass or C33500 Brass, is an alloy consisting of copper, zinc, and a small quantity of lead. This alloy is notable for its excellent machinability, fair ductility, and moderate strength. The primary components of C335 are copper (62.5%), zinc (36.5%), and lead (1%), making it a suitable material for a range of applications that require easy machining and reasonable strength.

Chemical Properties:

- Copper (Cu): 62.5%

- Zinc (Zn): 36.5%

- Lead (Pb): 1%

- Trace amounts of elements: Iron (Fe), Aluminum (Al), Silicon (Si), and Nickel (Ni)

Physical Properties:

- Density: 8.45 g/cm³

- Melting Point Range: 895-955°C (1640-1750°F)

- Tensile Strength: 290-560 MPa (42,000-81,200 psi)

- Yield Strength: 85-345 MPa (12,300-50,000 psi)

- Elongation: 12-45%

- Hardness (Brinell): 70-155 BHN

- Electrical Conductivity: 26% IACS (International Annealed Copper Standard)

C353

C353 Brass Grade, often referred to as High-Leaded Brass or C35300 Brass, is an alloy composed of copper, zinc, and a significant amount of lead. This alloy is valued for its exceptional machinability, adequate ductility, and fair strength. The primary constituents of C353 are copper (62%), zinc (35.5%), and lead (2.5%), making it an appropriate material for various applications requiring efficient machining and reasonable strength.

Chemical Properties:

- Copper (Cu): 62%

- Zinc (Zn): 35.5%

- Lead (Pb): 2.5%

- Minute quantities of elements: Iron (Fe), Aluminum (Al), Silicon (Si), and Nickel (Ni)

Physical Properties:

- Density: 8.44 g/cm³

- Melting Point Range: 890-950°C (1635-1740°F)

- Tensile Strength: 285-550 MPa (41,300-79,800 psi)

- Yield Strength: 80-340 MPa (11,600-49,300 psi)

- Elongation: 10-40%

- Hardness (Brinell): 65-150 BHN

- Electrical Conductivity: 25% IACS (International Annealed Copper Standard)

C365

C365 Brass Grade, also known as Leaded Muntz Metal or C36500 Brass, is an alloy made up of copper, zinc, and a considerable amount of lead. This alloy is recognized for its excellent machinability, reasonable ductility, and satisfactory strength. The primary components of C365 are copper (59%), zinc (39%), and lead (2%), making it a suitable choice for a range of applications that require efficient machining and acceptable strength.

Chemical Properties

- Copper (Cu): 59%

- Zinc (Zn): 39%

- Lead (Pb): 2%

- Trace elements: Iron (Fe), Aluminum (Al), Silicon (Si), and Nickel (Ni)

Physical Properties

- Density: 8.41 g/cm³

- Melting Point Range: 885-955°C (1625-1750°F)

- Tensile Strength: 280-540 MPa (40,600-78,300 psi)

- Yield Strength: 75-335 MPa (10,900-48,600 psi)

- Elongation: 8-35%

- Hardness (Brinell): 60-145 BHN

- Electrical Conductivity: 24% IACS (International Annealed Copper Standard)

C377

C377 Brass Grade, often referred to as Forging Brass or C37700 Brass, is an alloy composed of copper, zinc, and a trace amount of lead. This alloy is known for its excellent hot forging capabilities, good ductility, and moderate strength. The primary components of C377 are copper (58-61%), zinc (37-40%), and lead (1-2.5%), making it an ideal material for a variety of applications that require ease of hot forging and decent strength.

Chemical Properties:

- Copper (Cu): 58-61%

- Zinc (Zn): 37-40%

- Lead (Pb): 1-2.5%

- Trace amounts of elements: Iron (Fe), Aluminum (Al), Silicon (Si), and Nickel (Ni)

Physical Properties:

- Density: 8.44 g/cm³

- Melting Point Range: 890-935°C (1635-1715°F)

- Tensile Strength: 280-450 MPa (40,600-65,250 psi)

- Yield Strength: 90-260 MPa (13,050-37,700 psi)

- Elongation: 20-40%

- Hardness (Brinell): 65-110 BHN

- Electrical Conductivity: 27% IACS (International Annealed Copper Standard)

C385

C385 Brass Grade, commonly known as Architectural Brass or C38500 Brass, is an alloy consisting of copper, zinc, and a significant amount of lead. This alloy is valued for its outstanding machinability, good ductility, and moderate strength. The primary constituents of C385 are copper (57%), zinc (40%), and lead (3%), making it an appropriate material for a variety of applications that demand efficient machining and fair strength.

Chemical Properties:

- Copper (Cu): 57%

- Zinc (Zn): 40%

- Lead (Pb): 3%

- Trace amounts of elements: Iron (Fe), Aluminum (Al), Silicon (Si), and Nickel (Ni)

Physical Properties:

- Density: 8.40 g/cm³

- Melting Point Range: 880-955°C (1615-1750°F)

- Tensile Strength: 275-530 MPa (39,900-76,900 psi)

- Yield Strength: 70-330 MPa (10,150-47,900 psi)

- Elongation: 6-30%

- Hardness (Brinell): 55-140 BHN

- Electrical Conductivity: 23% IACS (International Annealed Copper Standard)

C400 – C40000 Brass Grades

The C400 to C40000 brass grades, also known as beta brasses, are characterized by a higher zinc content compared to alpha brasses, which bestows them with distinct attributes that cater to specific applications across various industries.

Advantages

- Strength and Hardness: C400 to C40000 brass grades are known for their impressive strength and hardness, making them suitable for applications requiring robust materials capable of withstanding significant wear and tear. These alloys are often used in load-bearing components and parts that experience high levels of friction.

- Corrosion Resistance: Similar to alpha brasses, C400 to C40000 brass grades exhibit good corrosion resistance due to their copper content. However, the higher zinc content can result in reduced corrosion resistance compared to their alpha counterparts. Nonetheless, these alloys are still suitable for many applications where corrosion resistance is required.

- Machinability: Beta brasses generally offer good machinability. This property enables them to be easily shaped, cut, and formed into various components, making them a popular choice for machining applications.

Common Applications:

- Marine equipment: underwater fastenings, hull components, and portholes

- Pump and valve components: impellers, housings, and shafts

- Condenser tubes: for heat exchangers in power plants and industrial processes

- Turned parts: precision components for machines and instruments

- Telecommunication equipment: connectors, contact pins, and sockets

- Electrical relay parts: offering low electrical resistance and good conductivity

- Ordnance components: specialized parts for military and defense applications

- Jewelry and accessories: cufflinks, bracelets, and brooches

- Antifriction applications: wear-resistant components in machines and equipment

- Boiler components: tubes, fittings, and heat exchanger elements

- Pinions and worm drives: for power transmission in machinery

- Sprinkler systems: fittings, nozzles, and valves for fire protection

- Water meters and fittings: for accurate measurement and control of water flow

- Reproduction of antique hardware: authentic-looking parts for restoration projects

- Marine-grade electrical components: switches, receptacles, and wiring devices resistant to saltwater environments

C443

C443 Brass Grade, often referred to as Admiralty Brass or C44300 Brass, is an alloy composed of copper, zinc, and a small amount of arsenic. This alloy is known for its excellent corrosion resistance, good ductility, and moderate strength. The primary components of C443 are copper (70%), zinc (29%), and arsenic (0.02-0.06%), making it an appropriate material for various applications that require resistance to corrosion and a fair level of strength.

Chemical Properties:

- Copper (Cu): 70%

- Zinc (Zn): 29%

- Arsenic (As): 0.02-0.06%

- Trace amounts of elements: Iron (Fe), Aluminum (Al), Silicon (Si), and Nickel (Ni)

Physical Properties:

- Density: 8.53 g/cm³

- Melting Point Range: 900-945°C (1650-1735°F)

- Tensile Strength: 310-480 MPa (45,000-69,600 psi)

- Yield Strength: 105-290 MPa (15,200-42,000 psi)

- Elongation: 25-55%

- Hardness (Brinell): 80-120 BHN

- Electrical Conductivity: 28% IACS (International Annealed Copper Standard)

C464

C464 Brass Grade, commonly known as Naval Brass or C46400 Brass, is an alloy consisting of copper, zinc, and a trace amount of tin. This alloy is appreciated for its exceptional corrosion resistance, particularly in seawater environments, as well as its good ductility and moderate strength. The primary constituents of C464 are copper (60%), zinc (39.25%), and tin (0.75%), making it an ideal material for various applications that necessitate corrosion resistance and decent strength.

Chemical Properties:

- Copper (Cu): 60%

- Zinc (Zn): 39.25%

- Tin (Sn): 0.75%

- Trace elements: Iron (Fe), Aluminum (Al), Silicon (Si), and Nickel (Ni)

Physical Properties:

- Density: 8.41 g/cm³

- Melting Point Range: 905-940°C (1660-1725°F)

- Tensile Strength: 300-450 MPa (43,500-65,250 psi)

- Yield Strength: 100-280 MPa (14,500-40,600 psi)

- Elongation: 20-45%

- Hardness (Brinell): 75-115 BHN

- Electrical Conductivity: 26% IACS (International Annealed Copper Standard)

C485

C48500 Brass Grade, also known as Leaded Naval Brass or C485 Brass, is an alloy composed of copper, zinc, tin, and a small amount of lead. This alloy is recognized for its impressive corrosion resistance, especially in marine environments, in addition to its good ductility and moderate strength. The primary components of C48500 are copper (58.5%), zinc (39%), tin (1%), and lead (1.5%), making it a suitable choice for a variety of applications that require corrosion resistance and decent strength.

Chemical Properties:

- Copper (Cu): 58.5%

- Zinc (Zn): 39%

- Tin (Sn): 1%

- Lead (Pb): 1.5%

- Trace elements: Iron (Fe), Aluminum (Al), Silicon (Si), and Nickel (Ni)

Physical Properties:

- Density: 8.39 g/cm³

- Melting Point Range: 900-935°C (1650-1715°F)

- Tensile Strength: 290-430 MPa (42,100-62,350 psi)

- Yield Strength: 95-270 MPa (13,800-39,150 psi)

- Elongation: 18-40%

- Hardness (Brinell): 70-110 BHN

- Electrical Conductivity: 23% IACS (International Annealed Copper Standard)

C770

C770 Brass Grade, commonly known as Nickel Silver or C77000 Brass, is an alloy composed of copper, nickel, and zinc. This alloy is appreciated for its excellent corrosion resistance, good strength, and attractive appearance. The primary components of C770 are copper (55-65%), nickel (10-30%), and zinc (18-27%), making it a suitable material for various applications that require corrosion resistance and appealing aesthetics.

Chemical Properties:

- Copper (Cu): 55-65%

- Nickel (Ni): 10-30%

- Zinc (Zn): 18-27%

- Trace amounts of elements: Iron (Fe), Aluminum (Al), Silicon (Si), and Lead (Pb)

Physical Properties:

- Density: 8.80 g/cm³

- Melting Point Range: 1000-1100°C (1832-2012°F)

- Tensile Strength: 450-800 MPa (65,250-116,000 psi)

- Yield Strength: 140-700 MPa (20,300-101,500 psi)

- Elongation: 2-40%

- Hardness (Brinell): 130-240 BHN

- Electrical Conductivity: 7% IACS (International Annealed Copper Standard)

Applications:

- Decorative and ornamental elements in architectural projects, such as door and window fittings, railings, and trim

- Musical instrument parts, including flutes, saxophones, and horns, due to its good strength and acoustic properties

- High-quality cutlery, flatware, and utensils due to its appealing appearance and corrosion resistance

- Watch and clock components due to its durability and resistance to tarnish and corrosion

- Jewelry making, including chains, pendants, and earrings, due to its attractive appearance and resistance to tarnish and corrosion

Disadvantages:

- Low electrical conductivity compared to other copper alloys, which may limit its use in specific electrical applications

- Moderate ductility and formability may not be suitable for specific formability applications

- Higher cost compared to other brass alloys, like C260 or C272, due to the presence of nickel

Here is a table for each grade and its main advantages:

| Brass Grade | Main Advantages |

|---|---|

| C360 | High machinability, excellent corrosion resistance, and good strength |

| C230 | Good corrosion resistance, excellent hot-working characteristics, and good strength |

| C210 | Excellent cold-working characteristics, good corrosion resistance, and good strength |

| C220 | Good machinability, excellent cold-working characteristics, and good strength |

| C260 | Good machinability, excellent cold-working characteristics, and good strength |

| C272 | Excellent machinability, good corrosion resistance, and good strength |

| C274 | Excellent machinability, good corrosion resistance, and good strength |

| C314 | Excellent machinability, good corrosion resistance, and good strength |

| C330 | Good hot-working characteristics, excellent corrosion resistance, and good strength |

| C335 | Good hot-working characteristics, excellent corrosion resistance, and good strength |

| C353 | Excellent cold-working characteristics, good corrosion resistance, and good strength |

| C365 | Good machinability, excellent cold-working characteristics, and good strength |

| C385 | Good machinability, excellent cold-working characteristics, and good strength |

| C443 | Excellent corrosion resistance in saltwater environments, good strength, and excellent heat-transfer properties |

| C464 | Excellent corrosion resistance in seawater and marine environments, good strength, and excellent hot-working characteristics |

| C485 | Excellent corrosion resistance in seawater and marine environments, good strength, and excellent hot-working characteristics |

| C770 | Excellent wear resistance, good corrosion resistance, and good strength |

Selecting the Right Brass Grade for Your Project

When choosing the appropriate brass grade for your CNC machining project, it’s essential to consider the specific requirements of your application. Factors such as machinability, strength, corrosion resistance, and cosmetic appearance should all be taken into account when making your decision. To aid in your selection process, consider the following guidelines:

Prioritize Machinability

If your project requires high-speed machining and tight tolerances, opt for a brass grade with excellent machinability, such as C36000 Free Cutting Brass. This grade is specifically designed for complex parts that demand precise machining.

Consider Corrosion Resistance

For components exposed to corrosive environments or harsh conditions, prioritize a brass grade with superior corrosion resistance. C46400 Naval Brass and C48500 Leaded Naval Brass are both excellent choices for marine and other corrosive applications.

Balance Strength and Machinability

In applications that require both strength and machinability, consider a brass grade that offers a good balance of these properties. C37700 Forging Brass is an excellent choice for parts requiring forging and machining, while C48500 Leaded Naval Brass combines strength with enhanced machinability.

Evaluate Aesthetic Requirements

If the appearance of your machined part is a crucial factor, choose a brass grade that offers a visually appealing finish. Most brass grades exhibit an attractive golden hue, but some, such as C36000 Free Cutting Brass, may have a slightly more yellow appearance due to their higher zinc content.

Make Sure that Your Machining Shop Supports the Brass Grade

At 3ERP, we take pride in offering top-of-the-line CNC brass machining services that bring your vision to life with unparalleled accuracy and precision. Our expertise in working with a variety of brass alloys ensures that your custom parts and components boast remarkable quality and performance.

Our cutting-edge CNC machine centers, combined with our team of highly experienced technicians, enable us to produce custom brass parts that meet even the most exacting specifications.

The Versatility of Brass in CNC Machining

Brass is a versatile and reliable material for CNC machining, offering a range of grades to suit various applications and requirements. By understanding the unique properties of each brass grade, you can make an informed decision about which is best suited to your project.

Whether you need excellent machinability, superior corrosion resistance, or a combination of strength and appearance, there is a brass grade that will meet your needs. Armed with this comprehensive guide, you can confidently navigate the world of brass grades and find the perfect material for your CNC machining project.