The injection molding process is not without its challenges, particularly when it comes to defects that can compromise quality. Recognizing and addressing injection molding defects is essential for manufacturers to ensure product quality, reduce waste, and optimize production efficiency. This guide goes deep into the most common issues, offering insights into their causes and outlining […]

Rapid injection molding method is revolutionizing how products come to life, blending efficiency and speed with engineering. This process makes it possible to manufacture many durable consumer and industrial items cheaper than everything else. It produces around 32% of plastics by weight. What is Rapid Injection Molding? Rapid injection molding is a type of injection […]

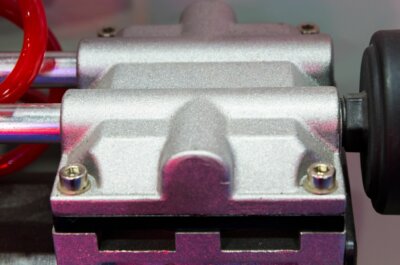

Diving into the world of manufacturing, one cannot overlook the pivotal role of injection molding machines. These devices are the unsung heroes behind the multitude of plastic products we use daily. From simple household items to intricate automotive components, the versatility and efficiency of injection molding machines make them indispensable in the production landscape. What […]

In the vast world of manufacturing, injection molding stands as an essential technique, used for creating a myriad of products with precision and efficiency. Let’s explore the multifaceted types of injection molding processes, each tailored for specific applications, materials, and advantages. The essence of injection molding, a process marrying innovation with technology, propels industries forward, […]

Thermoplastic injection molding offers a versatile and efficient method for mass-producing plastic parts. This guide delves into the intricacies of this technique, exploring its applications, advantages, and the science behind turning raw plastic into durable, functional components. What is Thermoplastic Injection Molding? Thermoplastic injection molding is a transformative process where thermoplastic polymers are melted, injected […]

Injection molding and urethane casting posses unique attributes and applications, shaping the world of production in distinct ways. Injection molding, a method known for its precision and efficiency in mass production of plastic products, contrasts sharply with urethane casting, celebrated for its flexibility and suitability for low-volume production This article delves into the depths of […]

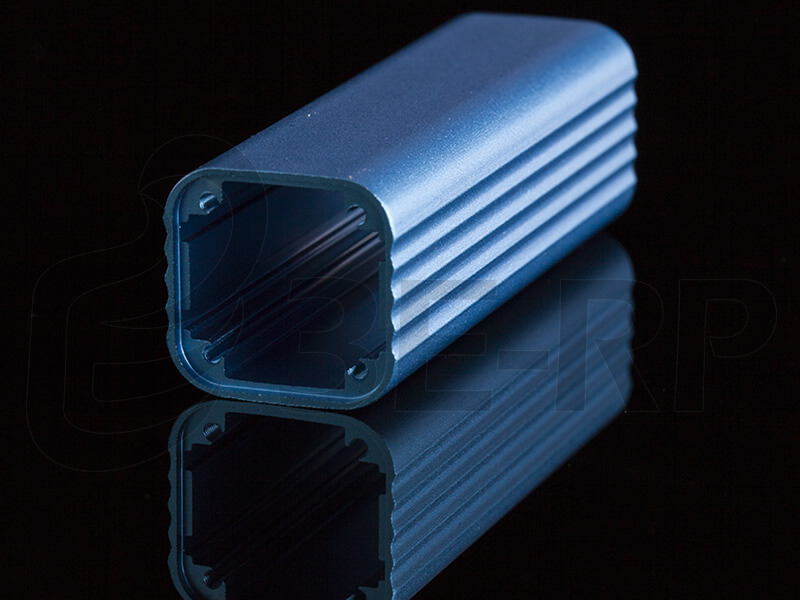

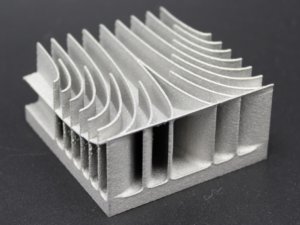

Injection molding and extrusion stand as pivotal manufacturing processes in the plastic industry, each with unique characteristics and applications. In this detailed exploration, we aim to dissect these methods, highlighting their distinct nature and operational principles. These processes, fundamental in shaping countless products around us, from intricate medical devices to robust automotive parts, represent the […]

The manufacturing world stands at a crossroads where precision meets innovation, particularly in the realms of Injection Molding and CNC Machining. Injection Molding and CNC Machining, while seemingly similar, operate on fundamentally different principles. Injection Molding, akin to casting, molds molten materials into predefined shapes. CNC Machining, in contrast, subtracts material through cutting and drilling […]

The injection molding process is ideal for making large batches of identical colored parts. Because pigments can be mixed into the molding material prior to production, there is generally no need for secondary finishing processes like painting or plating. Furthermore, the color goes through the entire part, not just the surface layer, so parts retain […]

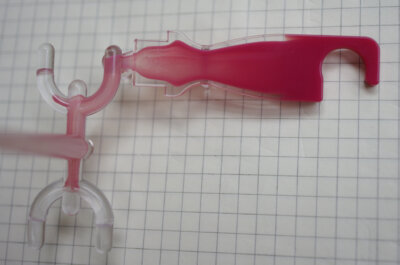

Engineers often require different material properties across different regions of a part, and they can achieve this goal in various ways. Often, parts will be designed as separate components that can be assembled using glue or fasteners. One component of the assembly may be made from a soft, pliable material, while another might be made […]

In the realm of manufacturing, particularly in the plastics industry, the durability and longevity of injection molds are pivotal for efficient production. Understanding the life expectancy of these molds is not just about numbers; it’s about grasping the intricate dance of material, design, and maintenance that dictates their lifespan. This article dives deep into the […]

The world of manufacturing was forever changed with the advent of injection molding, a groundbreaking technique crucial in shaping today’s plastic production landscape. This article delves into the rich history and transformative impact of injection molding, tracing its roots and exploring its pivotal role in the modern plastics industry. What Is Injection Molding? Injection molding […]

In the realm of manufacturing, injection molding tooling stands as a pivotal process, central to the production and manufacture of countless plastic components. This guide delves into the intricacies of injection molding tooling, unraveling its complexities and highlighting its significance in modern manufacturing. What is Tooling in Injection Molding? Injection molding tooling refers to […]

Many injection molding parts are made using single-cavity tooling. That is, each mold core and cavity is designed to produce a single component for each shot of molten plastic. But this doesn’t have to be the case. Some molds contain multiple cavities, which means that multiple components can be formed with each shot of plastic. […]

Thanks to its material versatility and efficiency, injection molding is the most widely used manufacturing process for plastic parts. It is most commonly used to process thermoplastic polymers, but can also be used for thermosets and elastomers. Injection molding is also one of the best manufacturing processes for processing polymer blends. Polymer blends are mixtures […]

Injection molding stands as a cornerstone in the manufacturing world, revolutionizing the production of parts across a myriad of industries. This method, known for its efficiency and versatility, shapes the way products are created, from everyday household items to intricate components in specialized fields. Injection molding, a manufacturing technique revered for its precision and scalability, […]

When delving into the world of manufacturing, the term ‘Injection Molding’ often surfaces as a cornerstone technique. Renowned for transforming industries with its precision and versatility, injection molding stands as a pillar of modern manufacturing. This article embarks on a comprehensive exploration of its numerous advantages, presenting a thorough insight into why it remains a […]

Injection molding, a cornerstone in the world of modern manufacturing, involves nuanced parameters that dictate its efficiency and quality. This guide dives deep into understanding and mastering these critical parameters. What is Injection Molding? Injection molding stands as a pivotal manufacturing process used extensively in producing complex and varied plastic parts. This technique involves melting […]

The world of manufacturing is continually evolving, and at the forefront of this innovation is injection molding. A critical aspect that determines the success of this process is the selection of the right material. Understanding the nuances of different injection molding materials is not just a matter of technicality but a cornerstone of quality and […]

Overmolding, the process of molding one material over a substrate made from another material, is a highly useful form of multi-material plastic injection molding. By combining soft and hard materials, overmolding makes it possible to make durable tools with soft hand grips, industrial components with built-in seals, and parts with high-friction surfaces. However, before making […]