3D printing is a digital prototyping and production technology that fabricates plastic or metal parts one layer at a time. It is also known as additive manufacturing because material is gradually added to build the part, as opposed to subtractive manufacturing processes — such as CNC machining, laser cutting, plasma cutting, water jet, stamping etc. — which remove material to form a raw material.

Although invented in the 1980s, 3D printing has massively grown in stature in the 21st century, with plastic 3D printing becoming an important prototyping method and high-quality metal additive manufacturing now common in industries like aerospace and medicine.

Different type of 3D printer work in different ways, though they typically share certain fundamental characteristics. All 3D printers are controlled by computer instructions (in the form of G-code) and work by turning raw material — e.g. powdered metal, liquid resin, or thermoplastic filament — into a new shape, one layer at a time, until a complete 3D object is built.

Although production-quality additive manufacturing is growing, 3D printers are still predominantly used as a prototyping tool. This is because they have very low startup costs, do not require tooling, and are very fast at printing one-off items.

This guide looks at the basics of 3D printing, including the main 3D printing technologies and materials, the advantages of 3D printing over comparable processes, and common applications of 3D printing.

3D printing technologies

FDM

Fused deposition modeling (FDM), sometimes known as fused filament fabrication (FFF), is a 3D printing technology that prints thermoplastic filament by heating it up to a molten state then extruding it through a nozzle on a moving printhead.

FDM works by extruding a steady flow of thermoplastic material from a printhead that moves along two axes (according to computer instructions); the extruded material forms a 2D shape on the print bed, cools, and ultimately solidifies. The printhead is then raised incrementally to move onto the next 2D layer, which is printed on top of the first, and this process repeats until the entire 3D shape is printed.

Because of its range of materials, affordability, and usability in non-industrial environments, FDM is the dominant 3D printing technology for consumers and is also widely used in professional environments as a prototyping tool.

Leading FDM 3D printer manufacturers include Stratasys, Ultimaker, MakerBot, FlashForge, Zortrax, and LulzBot.

SLA

Stereolithography (SLA) is a form of vat photopolymerization that uses a laser beam to make 3D shapes in a vat of photosensitive liquid resin.

The SLA process works by moving a highly focused laser beam in a precise pattern in the vat of resin. Because the resin is photosensitive, the laser beam is able to cure and solidify the resin, but only in the exact areas upon which it is focused. This allows the SLA 3D printer to form a solid 2D shape in the liquid resin before incrementally moving the build platform to move onto the next layer. (A related photopolymerization technology, digital light processing (DLP), uses a projector instead of a laser beam.)

SLA is an accurate 3D printing process that produces brittle plastic parts with a smooth surface. It is used for prototyping and in fields like dentistry and jewelry production.

Leading SLA 3D printer manufacturers include Formlabs, Creality, XYZprinting, and DWS Systems.

SLS

Selective laser sintering (SLS) is a 3D printing technology that uses a laser beam to sinter particles of powder material, typically nylon or polyamide.

During the SLS process, the print bed is covered in a thin layer of powder. A computer-controlled laser then draws a 2D shape in the powder, fusing particles and creating a solid shape. Once a 2D layer is complete, the print bed moves in increments to enable the printing of successive layers. Since the printed part is always surrounded by unsintered powder, it does not require support structures (a sort of printed scaffolding used in technologies like FDM to keep a part together).

SLS is used in both prototyping and low-volume production. Advantages include geometrical freedom and the ability to print several densely packed parts in one print job.

Manufacturers of SLS 3D printers include EOS, 3D Systems, and Prodways (industrial), as well as Sinterit, Sintratec, and Formlabs (desktop).

Multi Jet Fusion

Multi Jet Fusion (MJF), developed by printing giant HP, is another powder bed fusion 3D printing process for making polymer parts.

It is similar to SLS but, instead of using a laser to sinter particles of powder, it deposits a special ink on the powder that helps absorb infrared light; infrared light is then directed at the powder, causing fusion of particles.

MJF can be considered a combination of SLS and binder jetting — a process typically used to make metal parts.

Material Jetting

Not to be confused with binder jetting, material jetting is a distinct family of 3D printing processes in which inkjet printheads deposit material layer by layer.

The material jetting process works by selectively jetting a photoreactive material onto the print bed then curing it with UV light — somewhat like SLA, but without the vat of liquid. The process repeats, layer by layer, until the part is complete. Some printers use continuous jetting while others use drop-on-demand.

Material jetting 3D printers typically print with liquid thermoset photopolymers, and these can exhibit different material properties.

Leading material jetting 3D printer manufacturers include 3D Systems, Stratasys (PolyJet), and Xjet.

SLM

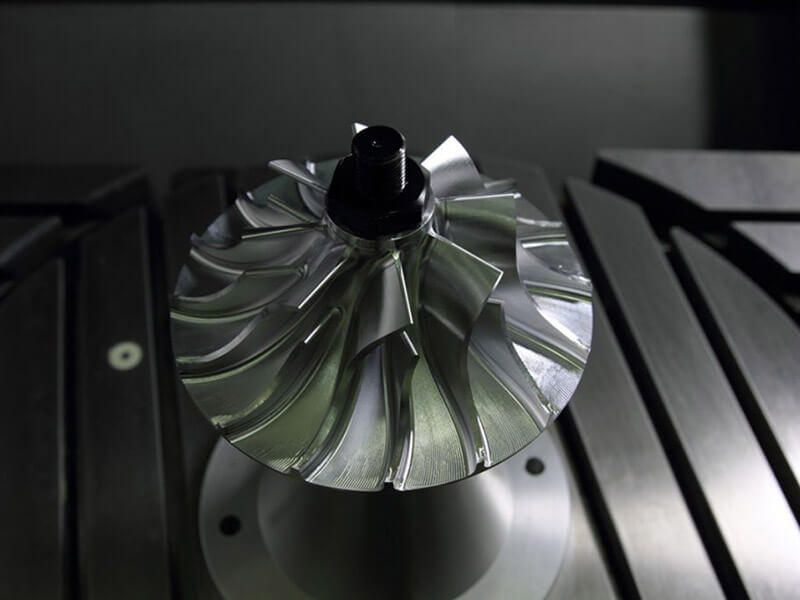

Selective laser melting (SLM) is a metal additive manufacturing process and one of the most important forms of 3D printing for end-use part production.

SLM, a form of powder bed fusion, resembles SLS in that it uses a laser directed at a bed of metal powder. However, particles can be fully melted rather than just sintered, and the process is used to process various metal powders instead of nylon and polyamide. Another difference is that SLM typically requires a sealed printing chamber containing inert gas. Improvements in SLM technology have made it a genuine alternative to machining and casting.

SLM has a variety of uses, from rapid metal prototyping to the production of end-use aerospace components and titanium medical implants.

Leading SLM 3D printer manufacturers include SLM Solutions and Renishaw.

DMLS

Direct metal laser sintering (DMLS) is another form of powder bed fusion additive manufacturing for metal parts.

DMLS resembles SLS in that it uses a laser to sinter particles; however, it is used for metals rather than nylons. DMLS also resembles SLM in many ways, but its laser does not fully melt the raw like SLM does. As such, DMLS is typically limited to metal alloys.

DMLS 3D printing is dominated by EOS, which developed the process (and the DMLS name) in the 1990s.

Binder Jetting

Binder jetting is a unique 3D printing process that uses a binder to make parts from metal, sand, or ceramic powders.

The binder jetting process works by coating the print bed in powder, then selectively spraying the powder with a binder (a sort of glue) to make a 2D shape. The glue-like binder bonds together particles of the powder instead of, for example, sintering them together. The build platform then moves to allow the printer to bind the next layer, and so on.

Binder jet parts typically need to be heat treated or infiltrated (with another material) after printing, to remove the binder material and strengthen the part.

Leading binder jetting 3D printer companies include 3D Systems, ExOne, Desktop Metal, Markforged, and HP.

3D printing materials

Thermoplastic filaments (FDM)

The large majority of materials used in FDM 3D printing are thermoplastic filaments available in spools of varying size. Thermoplastics melt when heated then re-solidify when cooled without changing their chemical composition; this makes them perfect for extrusion-type 3D printing.

A common all-purpose FDM thermoplastic filament is polylactic acid (PLA), which has a low melting point and is environmentally friendly. Acrylonitrile butadiene styrene (ABS), which has a higher melting point but extrudes more easily, is another popular choice. Other common FDM 3D printing materials include PETG and PC.

While most printable thermoplastics are rigid, there are some FDM flexible filaments such as TPE and TPU which are suitable for rubberlike parts.

Composite filaments (FDM)

Many FDM 3D printers are capable of printing thermoplastics reinforced with additives like glass or carbon fiber. These materials can have far superior strength to ordinary thermoplastics (although, since the glass pieces or chopped fibers are randomly oriented, the materials are typically weaker than printed continuous fibers, which require dedicated and expensive printing technology).

Liquid resins (SLA, DLP)

Materials for vat photopolymerization 3D printing processes like SLA and DLP come in the form of liquid photosensitive resins which contain monomers, oligomers, and photoinitiators. These resins are cured by a light source to make solid printed parts.

Different resins exist to suit different needs — for example, some are fully transparent, while some offer a higher level of impact resistance — but they do not have universal names like thermoplastics do. Rather, different producers of 3D printing resins produce different resin blends which often have simple labels like “standard resin” or “clear resin.”

Nylon/polyamide powders (SLS)

The most widely used SLS 3D printing material is nylon, an engineering thermoplastic that produces strong, stiff, and durable 3D printed parts.

SLS 3D printers sinter nylon in powder form, and there are a few different types of nylon powder (and other powders) that can be printed. Nylon 12 is a good all-purpose material for parts and prototyping, while Nylon 11 is particularly strong and ductile. Aluminium-filled nylon and TPU are other SLS powder options.

Metal powders (SLM, DMLS)

Metal additive manufacturing processes like SLM are compatible with metal powders that can be melted by the printer’s laser beam. These powders are often made by gas atomization, which produces spherical particles that flow easily.

A wide variety of metals are available as 3D printing powders for SLM and other powder bed fusion processes. These include high-strength, high-temperature titanium alloys; aluminum alloys; stainless steels; cobalt-chrome alloys; and nickel alloys.

3D printing software

3D printers are digital machines, and software therefore plays an important role in the 3D printing process. Although there is some overlap between types of 3D printing software (some software suites contain many different tools), there are four main categories: 3D modeling, STL repair, slicing, and print management.

3D modeling software

Computer-aided design (CAD) software, sometimes called 3D modeling software, is used to design 3D models on a computer screen which can ultimately be turned into physical 3D printed objects.

This kind of software may allow you to model 3D shapes visually, by selecting parameters, or by writing code. Features may include automatic modeling tools, CAM integration, and simulation tools.

Some common 3D printing 3D modeling software are TinkerCAD and Fusion 360 (both from Autodesk), SolidWorks from Dassault Systèmes, Rhino, and Blender.

STL repair software

STL repair or mesh repair software — sometimes packaged with CAD or slicing software — is designed to analyze and repair 3D printable files to facilitate smooth printing.

Popular standalone STL repair packages include Magics from Materialise and Netfabb/Meshmixer from Autodesk, while the aforementioned Fusion 360 and Blender come with STL repair tools.

Slicing software

3D modeling software creates mesh files which contain information about a 3D model, but a 3D printer cannot compute these files. This is where 3D printer slicing software comes in.

Slicing software cuts up a 3D mesh into individual layers which can be 3D printed in sequence, and exports the data about these layers as G-code, which a 3D printer can read and execute.

Slic3r, Cura, and Repetier are all common 3D printing slicing software applications.

Print management software

Some 3D printer users — especially those running multiple printers at once — may require 3D printing management software to manage print jobs, oversee machine performance and status, and monitor material supplies.

Print management tools include user-friendly web-based tools like OctoPrint, all the way to professional additive manufacturing execution systems (MES) like Materialise Streamics and Oqton FactoryOS.

3D printing advantages

There are numerous advantages to using 3D printing over alternative processes like CNC machining and injection molding. These include:

Speed: Especially for rapid prototyping of one-off parts, 3D printing is one of the fastest fabrication methods. Digital files can be sent to a 3D printer with minimal preparation. This can give companies a competitive edge, shortening R&D cycles and time-to-market.

Cost: Since no costly tooling is required, 3D printing is very cheap for fabricating one-off parts or short runs. There is also minimal material wastage, since the process is additive, not subtractive.

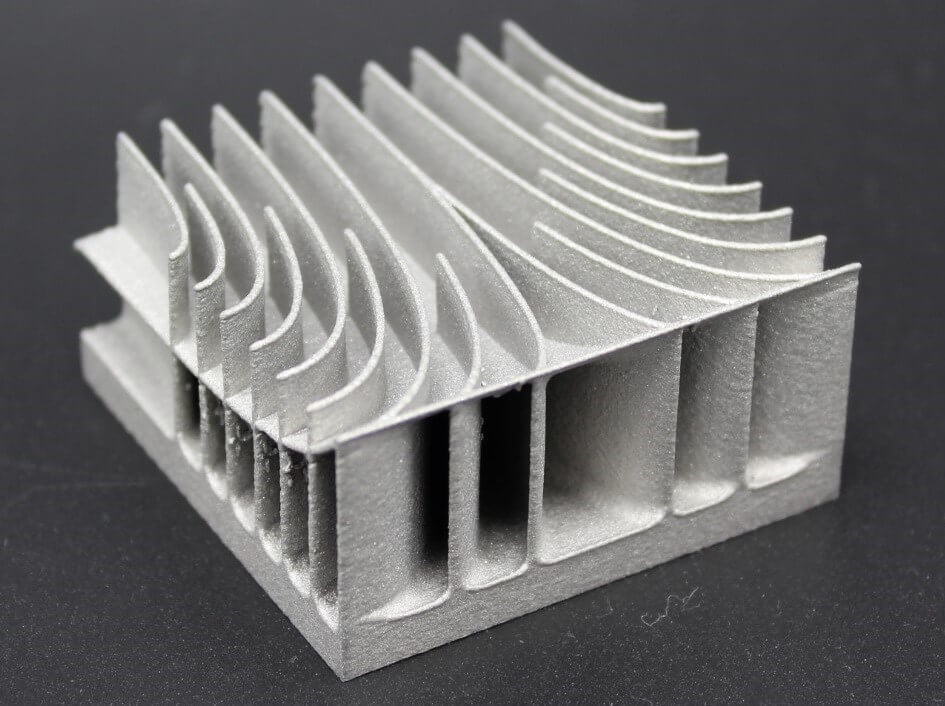

Geometrical freedom: 3D printing is subject to fewer design constraints than processes like injection molding, allowing for complex patterns and even complex internal sections. This is especially true of powder bed processes like SLS, since the powder supports the printed structure from all sides.

Consistency: Although 3D printing is often used for one-off parts and prototypes, it actually produces very consistent duplicates, since part quality is not dependent on factors like mold lifespan or tool wear.

Limitations of 3D printing include slowness in large volumes, limited part strength compared to subtractive and forming processes, material cost (FDM filament is more expensive than equivalent volumes of injection molding pellets, for example), limited material range, and limited options for coloration.

3D printing applications

3D printing has uses across a range of industries, both for rapid prototyping and short-run production.

Rapid prototyping

Across industries, a key application of 3D printing is the rapid prototyping of new parts during R&D. No other technology is as well equipped for instant fabrication of plastic or metal parts — even in non-factory environments.

3D printers can be utilized in-house by companies, while some businesses prefer to order 3D printed prototypes through service bureaus.

Medicine

3D printing can be used to fabricate medical components like patient-specific titanium implants and surgical guides (SLM), 3D printed prosthetics (SLS, FDM), and even 3D bioprinted human tissue. Components for medical equipment and machinery — X-ray machines, MRI equipment, etc. — can also be 3D printed.

Technologies like SLA and SLS are also widely used in the dental industry for models, prosthetics, and restorations.

Aerospace

The aerospace industry has been a major adopter of 3D printing technology, since it is possible to make very lightweight parts with an excellent strength-to-weight ratio. Example parts include simple components like cabin partitions (SLS), all the way to groundbreaking engine components (SLM) such as a 3D printed fuel nozzle tip developed and manufactured by GE.

Automotive

Automotive companies regularly use 3D printers to fabricate one-off spares and repairs, as well as rapid prototypes. Common 3D printed car parts include brackets, dashboard components, and antennae components (FDM).

More extreme examples include cars with large metal 3D printed structural components, such as early models from auto startup Divergent.

Jewelry and art

3D printing technologies like SLA are widely used (as an indirect fabrication process) in the production and repair of jewelry, while virtually all kinds of 3D printer can be used to create artwork and sculpture.

Construction

Advances in production-quality additive manufacturing have widened the scope of applications in construction and architecture. Concrete 3D printing, which works a bit like FDM but with very wide-nozzled extruders, plays a role in this industry, but more common 3D printing technologies like SLM can be used to make items like bridge structures.

3D printing file formats

3D printed parts can be designed using standard CAD software, but 3D printers can only read specific file formats. There are four main machine-readable 3D printing file formats.

STL: By far the most common 3D printer file format, STL contains information about part geometry in the form of tessellated triangles. It does not contain information like color, material, or texture. File size is proportional to detail, which can be an issue.

OBJ: The OBJ file format, less ubiquitous than STL, encodes 3D model geometry and can include free-form curves and free-form surfaces in addition to tessellations. It can also contain information about color, material, and texture, making it useful for full-color processes.

3MF: Invented by Microsoft, 3MF is an XML-based format with small file sizes and a good level of error prevention. It has not been widely adopted yet, but it is supported by companies like Stratasys, 3D Systems, Siemens, HP, and GE.

AMF: A successor to the STL format, AMF is much leaner and allows for the tessellation of curved triangles as well as flat ones — making it much easier to encode detailed parts in a range of shapes. Adoption of the format has been slow since its introduction.

3D printing settings and specs

3D printing uses some process-specific terminology that can be confusing to newcomers. These terms refer to printer settings and/or specifications that can affect how 3D printed parts turn out.

Infill

When making 3D printed parts, you may need to specify an infill percentage, which refers to the internal density of the part. A low infill percentage will result in a mostly hollow part with the bare minimum of material holding the shape together; a high infill will result in a strong, dense, heavier part.

Layer height

Layer height, sometimes referred to as Z-axis resolution, is the distance between one 2D layer of a part and the next. A smaller layer height means a finer resolution (and a higher possible level of detail) along the Z-axis, i.e. top to bottom. A small layer height is an indication of a high-quality printer, but users can specify larger layer heights for faster and more economic printing.

Print speed

A printer’s print speed, measured in millimeters per second, indicates the rate at which the machine can process the raw material. Like layer height, this value can be either an indication of a printer’s maximum speed or a user-determined value: slower printing speeds typically produce more accurate prints.

Print temperature

Applicable to processes like FDM, print temperature usually refers to the temperature of the hotend, the part of the printhead that heats the thermoplastic filament. Some FDM printers also have a heated print bed, the temperature of which will be specified by the manufacturer. In both cases, temperature is usually user-controllable.

Resolution

In 3D printing, resolution almost always refers to the smallest possible movement along the X and Y axes (width and depth), either by a laser beam (SLA, SLM, etc.) or a printhead (FDM). This value is harder to measure than layer height and not always proportional to it.

Shells

Like wall thickness in injection molding, shells (or shell thickness) refer to the thickness of an outside wall of a 3D printed part. When 3D printing, users typically have to select a number of shells: one shell = outside walls the thickness of the 3D printer nozzle; 2 shells = twice that thickness, etc.

3D printing in color

Given that 3D printing is mostly used as a prototyping tool, single-color prints suffice for most applications. However, there are a few options for 3D printing in color, including high-end material jetting printers, multi-extruder FDM printers, and post-processing options.

Jetting technologies

Major 3D printing companies like Stratasys, 3D Systems, and Mimaki have developed material jetting and binder jetting 3D printers that can print 3D models in full color just like 2D inkjet printers. However, these machines are expensive, and the parts do not always have excellent mechanical properties.

Multi-extrusion

Several FDM 3D printers come with dual (or more) printheads, allowing for two spools of filament — in different colors or even different materials altogether — to be printed simultaneously on the same print job. This is simple and affordable but usually limited to two colors.

Filament swapping

It is possible to make multicolor prints using a single-extruder FDM 3D printer. This involves pausing the print at certain points and replacing the filament spool with a filament of a different color. This is a very slow method of color application and does not offer very precise control over where each color goes.

Adding color after printing

Many 3D printed parts can be dyed, tinted, or painted after printing. Although this adds another step to the process, it often provides the best balance between quality and cost-effectiveness.

Post-processing 3D printed parts

Many 3D printed parts require at least some level of post-processing after they come off the print bed. This can include essential processes such as support removal or optional cosmetic processes like painting. Some processes apply to all or most 3D printing technologies, while some are technology-specific.

Support removal

3D printing technologies like FDM and SLA require the printing of support structures (vertical struts between the print bed and the part itself) so the printed object does not collapse while it is being fabricated.

These supports need to be removed when the part is finished. Some printers, such as dual-extrusion FDM machines, can print the support structures in a soluble material, which enables the supports to be easily disconnected from the actual part using liquid chemicals. Non-soluble supports need to be cut off the part manually, leaving a mark which may need to be sanded.

Washing & powder removal

Some 3D printing technologies (e.g. SLA) leave a sticky residue on parts, while others (SLM, SLS) can leave traces of powder. In these cases, parts need to be washed — manually or with a dedicated machine — or de-powdered using compressed air.

Heat treatment

Many key 3D printing technologies print parts in materials that, upon leaving the print bed, are not yet in their final chemical state. These are sometimes called “green” parts.

Lots of 3D printed metal parts require heat treatment after printing to increase layer fusion and remove contaminants. And binder jetting 3D printers, for example, produces parts that need debinding and sintering after printing to remove polymer binder from inside the metal parts.

Some resin 3D printed parts need to be post-cured after printing to increase their hardness and make them usable.

Surface finishing

3D printed parts can be subject to a large number of surface finishing techniques, from textural procedures like sanding and smoothing to visual procedures like painting and tinting. Some technologies, like FDM, can produce a fairly rough surface that requires sanding, while others, like SLA, produce a much smoother surface. See our full list of surface finishing services for more information.

Combining 3D printing with other technologies

3D printing does not have to be used as a standalone process. Instead of thinking of it as a competitor of CNC machining and injection molding, it can actually be complementary to these other manufacturing processes. Example combinations include:

3D printing the main section of a part, then CNC milling fine features to tighter tolerances

3D printing a master pattern for investment casting or vacuum casting

3D printing a component, then injection molding a structure over it with insert molding

Hybrid manufacturing systems exist that combine 3D printing with other technologies. Mazak’s INTEGREX i-400 AM and DMG MORI’s Lasertec DED, for example, can perform both 3D printing and CNC milling.

Will 3D printing replace other manufacturing processes?

Analysts have long speculated about whether 3D printing could make redundant other manufacturing processes, including:

Machining

Molding

Casting

However, despite the drive from AM hardware manufacturers to position 3D printing as an end-to-end production technology (see, for example, EOS’s Industry 4.0 initiative), in practice 3D printing remains limited to certain specific manufacturing jobs, especially low-volume manufacturing in specific materials.

3D printing has certainly overtaken other processes in some areas. For example, rapid prototyping in low-cost plastics like ABS is now dominated by 3D printing, since it is less expensive to print ABS than to machine it. 3D printing also seems to have cemented its place as the ideal tool for fabricating objects like patient-specific titanium medical implants: both the speed and geometrical flexibility of 3D printing are hard to match in specific situations like this.

Nonetheless, processes like CNC machining currently remain better at producing high-quality parts and prototypes in engineering materials like POM, PEI, PPS, and PEEK, while leaving a surface finish far superior to 3D printing. Additionally, processes like injection molding are still infinitely faster for the mass production of simple plastic components.

Furthermore, while additive manufacturing is seeing some of the most significant technological advances within manufacturing — allowing it to claim a bigger foothold in manufacturing as a whole — more established processes like CNC and injection molding are also being refined to produce parts of a higher quality.

3D printing will continue to take a larger share of manufacturing jobs, but it will not replace other technologies altogether.

How did 3D printing look 10 years ago?

A decade ago, the fledgling 3D printing industry was preparing itself for what it believed would be a 3D printing revolution: a 3D printer in every home, allowing families to 3D print new objects they might require, such as a replacement part for their fridge, a new toy for their children, or even components to build a second 3D printer.

Around 2012–2014, FDM 3D printer manufacturers like MakerBot aggressively marketed their 3D printers at the consumer market, attempting to convince normal people that a 3D printer could improve their home life and their work life. However, it was clear that these companies were trying to exploit the novelty factor of 3D printing and that their products had little practical use; a MakerBot press release from 2012 seems to prove this: “Make an entire chess set with the press of a button. Friends, classmates, co-workers, and family will see the things you make and say ‘Wow!'”

Just a few years later, this so-called 3D printing revolution had evidently failed, and many 3D printer manufacturers started to realign their targets, moving from the consumer sphere to the professional and industrial markets, where there were more concrete (and lucrative) applications of additive technology.

Furthermore, those already in the professional and industrial sphere — companies like 3D Systems and Stratasys — began trying to break down the idea of 3D printing as a prototyping technology, positioning it instead as a viable mass production tool (which could obviously be more lucrative for the 3D printing industry, since manufacturers would be expected to fill entire factories with 3D printers, buy 3D printer management software, and hire 3D printing consultants).

How will 3D printing look in 10 years?

3D printing companies have abandoned the prospect of putting a 3D printer in every household. However, in 10 years they may expect to see some form of additive manufacturing in a larger number of factories.

Although 3D printing is less of a talking point amongst ordinary people today than it was in 2012, the technology continues to pick up pace in the professional and industrial world.

According to a recent report, market research company 3DPBM Research expects metal additive manufacturing to grow in value from $1.6 billion in 2020 to $30 billion by 2030, and this is largely down to the repositioning of AM as a production tool and the development of more high-performance engineering materials. (That being said, 3D printing will remain a valuable prototyping tool across many industries, and prototyping applications will benefit equally from technological improvements.)

It’s not just metal AM that is growing, however. Technologies like Multi Jet Fusion from HP have opened up new possibilities in plastic printing, while innovators like Carbon have developed novel high-speed processes in the photopolymerization category. Niche areas like 3D bioprinting and micro 3D printing are also regularly breaking new ground, while composite 3D printing (e.g. continuous carbon fiber 3D printing) is also on the rise: IDTechEX expects the composite 3D printing market to be worth $1.7 billion by 2030.

In short, 3D printing will gradually become a serious competitor to other manufacturing processes across many disciplines.

How is 3D printing developing in China?

Although China boasts only a few notable 3D printer manufacturers — UnionTech (SLA), Farsoon (DMLS, SLS), Shining 3D (FDM, DLP), and Creality (FDM, DLP, SLA) are some of the more well-known names — China and the Asia-Pacific region is one of the fastest-growing 3D printing markets, showing widespread adoption (partly thanks to government incentives).

At present, AM activity in China is concentrated in Shanghai, Xi’an, Guangdong (where 3ERP is headquartered), and the Bohai Economic Rim, which includes Tianjin, Hebei, Liaoning, and Shandong. Some major western AM companies like 3D Systems, Stratasys, and EOS have offices in Shanghai.

Although production of Chinese 3D printers is dominated by FDM and resin technologies, around half of printers sold in China are for industrial use (as opposed to personal or small-scale professional use).

In October 2020, market research company CONTEXT found that China’s 3D printing market had been far more resilient in the face of the pandemic than other markets and was playing a major role in the recovery of the global 3D printing market.

How to outsource 3D printing services?

Investment in 3D printing hardware and software is not suitable for all businesses, and many successful companies outsource their 3D printing needs to third parties, such as online 3D printing service bureaus (for one-off projects) or with prototyping and manufacturing partners like 3ERP (for one-off projects or repeat orders).

When outsourcing 3D printing services, it is important to consider whether your business needs design and production services, or production services only. (Bear in mind that a poorly executed 3D model may not 3D print successfully.)

In general, however, ordering 3D printed parts from a third party is simpler than ever. Many manufacturers are able to commence 3D printing with just a digital 3D model, although more important projects may also require a technical drawing to convey extra information such as materials, colors, and tolerances. Some 3D printing service providers (3ERP included) will offer advice on suitable 3D printing technologies and materials for your project.

See our 3D printing services in full, including available technologies and materials, or request a quote for your 3D printing project.