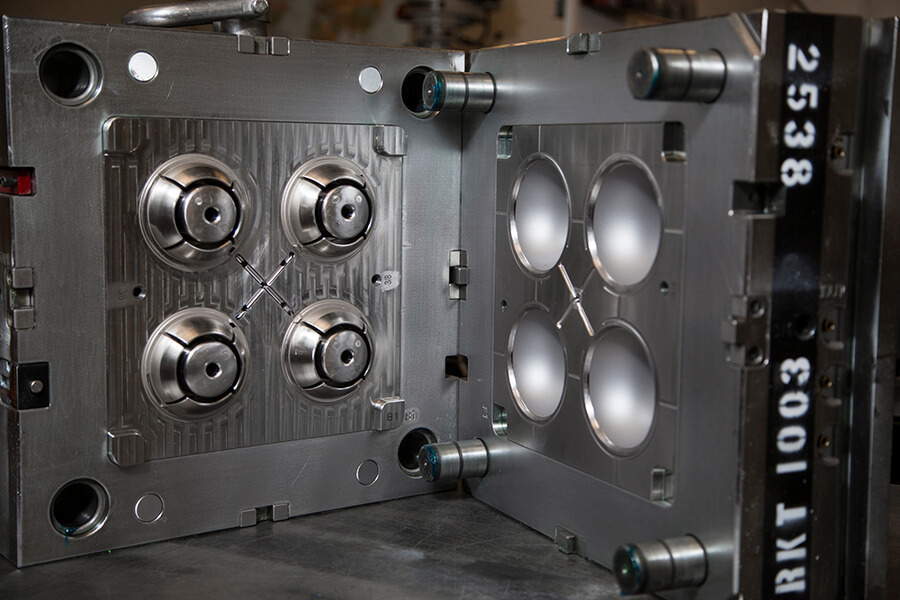

Many injection molding parts are made using single-cavity tooling. That is, each mold core and cavity is designed to produce a single component for each shot of molten plastic. But this doesn’t have to be the case. Some molds contain multiple cavities, which means that multiple components can be formed with each shot of plastic.

There are pros and cons to multi-cavity molding. Employing multiple cavities can can drastically increase efficiency, enabling rapid mass production of identical components. Some multi-cavity molds contain four or eight cavities, while others — those for simple bottle caps, for example — might contain 64 or even 128. However, multi-cavity tooling brings additional design considerations such as sprue and gate placement, as well as an increased need to consider material flow, as the molten plastic typically needs to take a more circuitous route to each cavity.

This article looks at the main reasons to use multi-cavity injection molding. It considers the key benefits of multi-cavity molding, including production capacity and batch consistency, while also noting the challenges and unique design requirements when using multi-cavity molds.

What is multi-cavity molding?

Multi-cavity molding, sometimes called multiple impression molding, is the process of using tooling with multiple cavities in order to mold several parts simultaneously with a single plastic shot.

Molding with multi-cavity mold is standard practice in injection molding. All injection molding companies, 3ERP included, are capable of producing molded parts using multi-cavity molds. However, design of a multi-cavity mold requires careful consideration: to ensure each cavity is filled evenly and with the same amount of pressure, gates, sprues, and runners must be carefully located.

Multi-cavity molding should not be confused with multi-shot molding, which involves injecting two or more shots of (usually different) plastic material into the same mold. Among other things, this process is used to make overmolded parts with hard and soft sections.

Types of multi-cavity molds

Multi-cavity molds can be divided into two main categories: a) multi-cavity or multi-impression molds and b) family molds. These are used to achieve different molding outcomes.

Multi-cavity molds

Multi-cavity molds contain more than one cavity of the same part. They are used to make batches of a single component, and typically employ symmetry to ensure even filling of each identical cavity. The number of cavities depends on the size of the tooling, the size of the component, and the customer requirements. The mold might contain anywhere between two and 128 cavities.

Family molds

Family molds also contain multiple cavities, but the cavities can be different from one another, enabling the production of several unique components within a single mold. Family molds are often used for low-volume molding, where the production of multiple tools would be prohibitively expensive. However, they are vulnerable to part defects, as the asymmetry of the cavities makes it difficult to fill them evenly, so they are rarely used for critical parts.

One common example of a family mold is the hobbyist model kit (for model airplanes, Warhammer figurines, etc.). These molded kits come with the sprues still attached and contain multiple different components for the hobbyist to assemble themselves.

Benefits of multi-cavity molding

There are several reasons to use multi-cavity molding over single-cavity molding. The most important reasons are production speed and efficiency, potential cost savings, and, in some cases, improved color consistency.

Efficiency

The main reason to use multi-cavity molding is the massive increase in production efficiency it can offer. When using a single-cavity mold, each molding must cool down individually before ejection. With a multi-cavity mold, on the other hand, it is possibly fill and cool four, eight, or more moldings simultaneously, greatly shortening production times.

While multi-cavity molds can take longer to design and each mold takes slightly longer to fill with molten plastic, the ability to make significantly more parts per cycle easily nullifies these marginal delays. Multi-cavity molding is therefore widely used for the mass production of identical components.

Part cost

Using multi-cavity tooling can result in significant cost savings, especially when making parts in large quantities. While the initial outlay is higher due to the larger and/or more complex molds, the ultimate cost per part can be much lower, as less machine time and human labor is required. When dealing with mass production, these factors are far more significant than the initial outlay.

Color consistency

Making several duplicate components within a single mold can result in greater color consistency between individual moldings. Colorants may be added to the plastic granules using a gravimetric blender or by manual measurement, but it is not always possible to ensure perfect consistency across cycles. By molding multiple parts within a single mold and a single cycle, it is easier to achieve consistent coloration — at least between parts produced during the same cycle.

Limitations of multi-cavity molding

Despite its many advantages, multi-cavity molding can pose challenges, meaning it is not ideal for every molding project. The main disadvantages of multi-cavity molding include lack of part consistency, tooling complexity, and difficulty achieving ideal flow conditions.

Material flow challenges

Multi-cavity molds require a more complex system of sprues, runners, cooling channels, and vents than single-cavity molds. And with material flowing in several different directions, it can be difficult to find the right flow parameters that will lead to consistent filling and batch consistency. In general, it is much easier to achieve optimal, defect-free filling with a single-cavity mold.

That being said, material flow challenges can be mitigated when using less viscous materials such as liquid silicone rubber.

Mold cost

Partly due to the design complexities mentioned above, multi-cavity molds are more expensive to produce than single-cavity molds. This makes them unsuitable for low-volume production, as the ultimate reduction in cost-per-part may not be enough to offset the higher upfront costs associated with creating the tooling.

Multi-cavity molding with 3ERP

3ERP has years of experience making injection molded parts with single-cavity and multi-cavity tooling. We can handle small orders for just a few hundred prototype moldings — where single-cavity molds or family molds may be suitable — all the way up to production molding for millions of units, where multi-cavity molding may be more suitable. Most importantly, our skilled engineers are capable of designing the tooling for your part designs, leading to high-quality, consistent moldings.

Contact us for a free quote on your next injection molding order.