Galling is a common problem with metal parts. It happens when two sliding metal surfaces unexpectedly stick to one another, causing frictional damage and ultimately unwanted cold welding. Most often seen in sliding parts like threads, fasteners, bearings, cylinders, and pistons, galling can also occur during metalworking — when microscopic pieces of the workpiece adhere […]

Injection molding can process a wide range of materials. In addition to metals and thermosets, injection molding is suited to a large number of thermoplastic polymers, from commodity polymers like ABS to high-performance materials like PEEK. Engineers will select a thermoplastic based on the requirements of the molded part. Some moldings need to be impact-resistant, […]

Metal parts made using processes like CNC machining can be colored in different ways to meet customer specifications. For common metals like aluminum, two of the most common metal coloring techniques are powder coating and painting. Each coloring process has its own advantages and disadvantages, though both are suitable for most metals. They are more […]

Coextrusion or co-extrusion is a plastic manufacturing process that uses two or more extruders to make a single extrusion. It is used to make extrusions with the material properties of two different plastics. The coextrusion process is used in the production of films, multilayer tubing, food packaging, and other applications where a combination of polymers […]

Regularly used for professional or industrial plastic prototypes, the process of urethane casting is also a godsend for hobbyists who want to make small plastic miniatures, models, toys, and figurines. With a good level of detail and very low up-front costs compared to injection molding, urethane casting could be your next solution for tabletop gaming […]

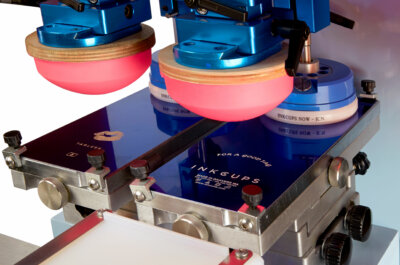

Pad printing, a form of surface finishing available for parts produced via CNC machining, injection molding, and other processes, is a unique printing process suitable for printing on 3D shapes with non-flat surfaces. Fast and repeatable, pad printing allows for a 2D image or pattern to be printed onto a 3D object. It is a […]

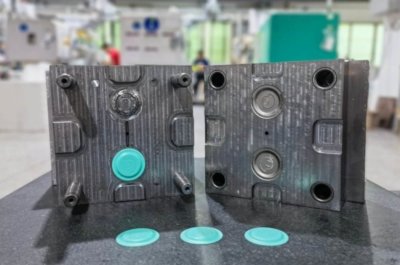

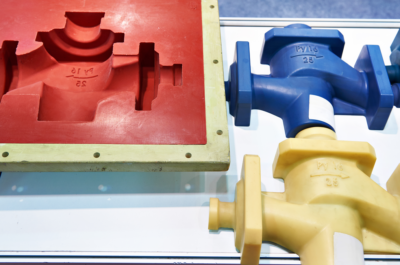

Rapid tooling enables engineers to get moldings much faster than they would with production molds. Via machining or additive manufacturing, rapid tooling massively reduces toolmaking lead times, making it possible to obtain accurate prototypes of molded parts or even low-volume production parts. There are many key advantages to using rapid tooling systems. First and foremost, […]

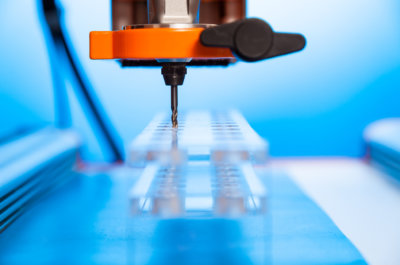

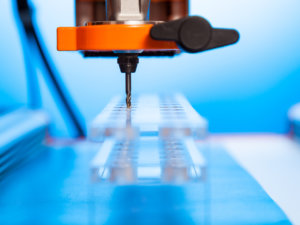

For industrial manufacturing processes like sheet metal fabrication, machinists have several pieces of cutting equipment available to them. In addition to standard CNC machines that use sharp metal cutting tools, there are other options such as laser cutters, water jet cutters, and plasma cutters. Each of these industrial tools has its own unique advantages and […]

Flash or flashing is one of the most common problems associated with injection molding, the most widely used manufacturing process for plastic parts. Injection molding flash is when a line of excess material builds up on the outside of a molded part, typically after leaking through the parting line of the mold. A small amount […]

Maintaining the condition of the putting green is essential to a successful round of golf. Custom golf divot tools, made using 3D printing of CNC machining, are a great way to improve your putting game while personalizing the golfing experience. Few sports are as dependent on the condition of the playing field as golf. In […]

Digital 3D files have changed the way engineers work with manufacturers. Engineers can now design a part using CAD software, send the digital file to a manufacturer, and have the manufacturer make the part directly from the file using digital manufacturing techniques like CNC machining. But although digital files have made manufacturing faster and simpler, […]

Plastic fabrication is essential to most industries. From polystyrene food packaging to industrial components made from engineering-grade PEEK, plastic fabrication contributes hugely to life as we know it. Without the ability to make plastic parts, we would need to develop radically new systems of production. But plastic fabrication comprises many different methods. Injection molding, plastic […]

Galvanization is a process for adding a coating of zinc to the surface of steel or iron. Since the zinc acts as a sacrificial coating, it protects the steel or iron underneath and can therefore extend the lifespan of metal parts. But galvanization is a complex process that can be carried out in several ways. […]

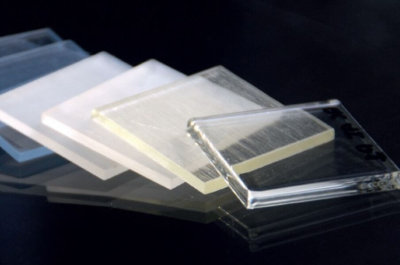

Clear parts and prototypes have a huge variety of applications. Fortunately, they’re also fairly easy to make, with a wide range of materials and prototyping technologies at your disposal. This article goes over the basics of transparent and translucent parts: why you might need them, what materials you can use, which manufacturing technologies are available, […]

Sheet metal fabrication, the practice of manipulating flat pieces of metal into new shapes, is a practical and low-cost solution for making parts like brackets, enclosures, and kitchen equipment. It is one of the most efficient ways to make very large, simple products that don’t have highly detailed features. However, engineering successful sheet metal parts […]

Why do use Injection Molding? Injection Molding is typically a manufacturing process for making a large number volume of products and it is hugely used in mass-production processes. It can able to produce the same products thousands or even millions of times in series. There are different benefits customers can reap from this process. Alongside […]

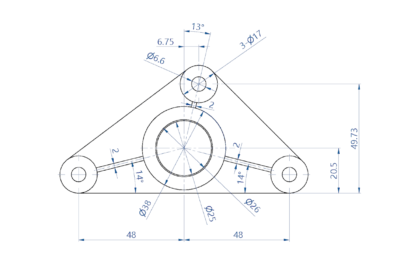

Technical drawings (and the process of drafting) are a means of conveying information between engineers and manufacturers. Technical drawings usually complement digital CAD files, providing extra information that can’t easily be conveyed by a part’s shape alone. In the world of prototyping and manufacturing, we typically deal with a certain subtype of technical drawings known […]

Rapid Injection Molding is precisely defining its name as this process ensures speed and quality during manufacturing. However, it is one of the most convenient, popular, and cost-effective manufacturing processes for critical design during molding procedure and widely appreciated by various industries. All you just need to find out the best source that would meet […]

How Does Plastic Injection Molding Work? Typically the Plastic Injection Molding process involves aluminum mold that does not require cooling channels. A professional manufacturer can efficiently produce high-quality parts as per clients’ concerns. In this process, the hot melted resin shot into the mold cavity through the gates and hence converted into molded parts. Once […]

Plastic Injection Mold Making is a specialized process that can produce parts precisely and accurately. This process is highly efficient, simple, and cost-effective. Most of the companies are using this technique to meet their clients’ demand in the market. Plastic injection molding has been known as a dependable, deep-rooted manufacturing procedure for many years. All […]