Injection molding, a cornerstone in the world of modern manufacturing, involves nuanced parameters that dictate its efficiency and quality. This guide dives deep into understanding and mastering these critical parameters.

What is Injection Molding?

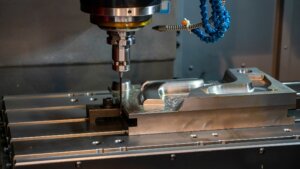

Injection molding stands as a pivotal manufacturing process used extensively in producing complex and varied plastic parts. This technique involves melting metal or plastic pellets and injecting the molten plastic into a mold cavity, where it cools and solidifies into the desired shape. Its versatility in handling a range of materials and complexities makes it a preferred choice in industries from automotive to consumer goods.

Why Are Injection Molding Parameters Critical?

The heart of injection molding’s success lies in its parameters. Each aspect, from injection pressure to mold temperature, plays a vital role in determining the quality and efficiency of the end product. Precision in these parameters ensures reduced defects, enhanced strength, and consistency in production.

Understanding and optimizing these parameters is not just a technical necessity but also a strategic advantage in the competitive manufacturing landscape.

What are the Core Parameters of Injection Molding?

Injection molding parameters are the critical factors that influence the quality and efficiency of the molding process. They include:

- Injection Pressure: This determines how the molten plastic is injected into the mold. Proper pressure ensures complete cavity filling and impacts the product’s structural integrity.

- Mold Temperature: A crucial factor affecting the cooling and solidification of the plastic. It influences the surface quality and dimensional stability of the final product.

- Injection Speed: The rate at which the plastic is injected into the mold, affecting the filling process and the quality of the molded part.

Additional Parameters

- Back Pressure: Controls the quality of the plastic melt.

- Melting Temperature: Dictates the fluidity of the plastic.

- Clamping Force: Ensures the mold remains closed during injection.

How Does Temperature Influence Injection Molding?

Temperature regulation in injection molding is a balancing act of precision and control, vital for achieving optimal product characteristics. It encompasses several elements, each playing a pivotal role in the molding cycle.

Melt Temperature

Melt temperature, the heat at which the polymer becomes fluid enough for injection, is crucial for the process’s success. For instance, ABS plastic typically requires a melt temperature ranging from 210°C to 270°C.

This temperature needs to be precisely controlled to ensure smooth flow and complete filling of the mold cavity, directly influencing the injection molding techniques and the quality of injection molded products. Improper melt temperature can lead to issues like poor surface quality, inadequate strength, or warping in the final product.

Mold Temperature

The mold temperature, another key parameter, significantly affects the cooling process and final properties of the molded part. For materials like polycarbonate, the mold temperature usually ranges between 80°C and 120°C.

This parameter impacts factors such as cooling time, dimensional stability, and surface finish. A well-regulated mold temperature ensures reduced stress and shrinkage, contributing to the overall product quality and durability.

Temperature Control

Temperature control in injection molding is not just about reaching the right temperature but maintaining it consistently throughout the production process. It encompasses the management of barrel temperature, nozzle temperature, and the temperature of the mold.

These factors collectively influence the melting, flow performance, and solidification of the plastic. Advanced control systems are employed to monitor and adjust these temperatures, ensuring a stable and efficient molding process.

What Role Does Pressure Play in Injection Molding?

In the intricate world of injection molding, pressure stands as a cornerstone parameter, deeply influencing every aspect of the molding cycle. From the way molten plastic flows into the mold to the final structural integrity and surface quality of the product, understanding the different types of pressures and their roles is crucial.

Injection Pressure

Injection pressure, the force exerted to push the molten plastic into the mold cavity, is a vital factor in the injection molding process. This pressure needs to be high enough to ensure a good flow of the material, filling the mold completely and accurately.

For many applications, the injection pressure might be around 500 to 1500 bar. The correct setting of injection pressure is key to achieving optimal surface quality and dimensional accuracy of the injection molded parts. It also plays a significant role in the distribution of materials within the mold cavity, impacting the final strength and properties of the product.

Holding Pressure

Once the mold is filled, holding pressure comes into play. This is a lower pressure applied to the molten plastic to pack the material into the mold and compensate for any material shrinkage during cooling. Typically, holding pressure can be approximately 50-65% of the injection pressure.

Proper management of holding pressure is essential for minimizing defects like sink marks and ensuring consistent part weight and dimensions. This pressure helps maintain the integrity of the product during the crucial stage of cooling and solidification, ensuring that the final product meets the desired quality standards.

Nozzle Pressure

Nozzle pressure in injection molding is the force exerted by the machine to push molten plastic through the nozzle into the mold. This parameter is critical for ensuring the material fills the mold cavity effectively, influencing the quality of the final product. Optimal nozzle pressure varies depending on the material’s viscosity and the design of the part being molded.

Mold Locking Pressure

Mold locking pressure is the force applied to keep the mold closed during the injection process. This pressure must be sufficient to counteract the force of the injected material, preventing mold flash and ensuring the integrity of the molded part. It is adjusted based on the size and complexity of the mold, as well as the injection pressure used.

Why is Injection Speed Important?

In the sophisticated process of injection molding, the parameter of speed is not to be underestimated. Injection speed refers to the rate at which the molten plastic is introduced into the mold. This aspect of the process plays a critical role in determining the quality and efficiency of the final product.

Injection Speed

The injection speed is a dynamic parameter that can greatly influence the characteristics of the final part. In the intricate dance of the injection molding process, the speed at which plastic enters the mold impacts everything from the material’s flow performance to the product’s surface quality. For a medium-sized part, a typical injection speed might range from 50-100 mm/s.

A well-calibrated injection speed ensures that the molten plastic fills the mold cavity in an optimal manner.

Too slow, and the material may start solidifying before the mold is completely filled, leading to defects and poor structural integrity.

Conversely, too fast, and the plastic might create stress within the mold, leading to warping or other surface imperfections. Furthermore, the speed must be adjusted based on the material used, as different plastics have varying flow properties and cooling rates.

Screw Speed

Screw speed in injection molding is the rate at which the screw rotates to mix and inject the molten plastic. This speed affects the quality of the mix and the consistency of the injection. Proper adjustment of screw speed is vital for optimal material homogenization and to avoid issues like material degradation or air entrapment.

Recovery Rate

The recovery rate in injection molding refers to the speed at which the screw draws new material into the barrel after each injection cycle. This rate impacts the cycle time and the efficiency of the production process. A faster recovery rate can increase production speed but may require careful balancing to avoid material degradation.

Shrinkage Rate

Shrinkage rate is the percentage of reduction in size a plastic part undergoes as it cools and solidifies in the mold. This parameter is crucial for achieving dimensional accuracy in the final product. Factors like material type, mold temperature, and cooling time significantly influence the shrinkage rate.

Clamping Force

Clamping force is the pressure used to hold the mold closed during the injection and cooling stages. Adequate clamping force is essential to prevent mold opening due to internal pressure, ensuring the production of defect-free parts. The required clamping force depends on the projected area of the part and the injection pressure.

Cooling Time

In the meticulously timed process of injection molding, cooling time is a critical factor that significantly influences the dimensional stability and quality of the final product. This phase allows the molten plastic within the mold to cool and solidify into its intended shape.

For instance, in the case of a simple, thin-walled plastic part, the cooling time might typically range from 10-30 seconds. This duration is vital to ensure that the part has solidified enough to maintain its shape upon ejection from the mold.

The cooling time must be accurately calculated and controlled, as too short a time might lead to parts being ejected prematurely, causing deformation or warping.

Conversely, excessively long cooling times can reduce the overall efficiency of the production process and increase cycle times. The cooling process’s effectiveness also hinges on the mold temperature and the thermal properties of the plastic material used, necessitating precise control systems to regulate and monitor these parameters.

Back Pressure

Back pressure in injection molding refers to the pressure applied during the retraction of the screw in the injection molding machine. This pressure is crucial for homogenizing the plastic melt, ensuring consistent quality across production cycles.

Typically, a common back pressure setting might be in the range of 5-20 bar. The application of back pressure aids in the proper mixing and melting of the polymer materials, leading to an even distribution of pigments, fillers, and other additives.

This uniformity is essential for achieving the desired surface quality and mechanical properties in the final product. Moreover, appropriate back pressure helps in reducing the presence of air and other volatiles in the melt, which can otherwise lead to defects in the molded parts.

Thus, back pressure is not just a step in the process; it is a significant contributor to the molding process’s overall efficiency and the quality of the injection molded products.

Cycle Time

Cycle time in injection molding encapsulates the total time required to complete a full cycle of the process, encompassing injection, cooling, and mold opening stages. For a small and simple part, the cycle time might be as low as 30 seconds.

This parameter is a critical measure of the efficiency of the injection molding production process. Shorter cycle times translate to higher production speeds and increased output, which are vital in high-volume manufacturing scenarios.

However, optimizing the cycle time requires a delicate balance. While reducing cycle time can lead to higher productivity, it should not come at the cost of product quality.

Factors such as the complexity of the part design, the material used, and the specific process parameters like injection speed, pressure, and temperature settings all interact to determine the feasible cycle time.

Therefore, achieving an optimal cycle time is a result of meticulously balancing these various factors to ensure both efficiency and quality in the injection molding process.

How to Optimize Injection Molding Parameters for Quality Production?

Optimizing injection molding parameters is pivotal for ensuring the highest quality in production. The process’s complexity requires a nuanced approach, balancing various factors to achieve optimal results. Here, we discuss strategies for parameter optimization, providing actionable insights and real-life examples.

Best practices

- Regularly Monitor and Adjust Parameters: Keeping a close eye on parameters like injection pressure, mold temperature, and injection speed helps in maintaining consistent quality. For example, a slight increase in mold temperature might be required for materials with higher viscosity to ensure proper flow.

- Use of Advanced Control Systems: Implementing automation in operations can significantly enhance precision. For instance, using computer-controlled systems for temperature and pressure adjustments can lead to more consistent quality.

- Thorough Material Understanding: Different materials react differently under various conditions. Understanding the specific requirements of each material used, like melting temperature and cooling rate, is crucial.

- Mold Design Optimization: The design of the mold should facilitate optimal flow and cooling. For instance, uneven wall thickness can lead to differential cooling and warping.

- Avoid Over-Pressurizing: Excessive injection pressure can cause stress marks and reduce the life of the mold. A balanced approach to pressure settings is key.

- Optimize Cooling Time: Ensure that cooling time is adequate for the part to solidify without deforming but not so long that it slows down the production cycle. For example, a complex part with thick walls will require a longer cooling time than a simple thin-walled part.

Common Mistakes to Avoid

- Neglecting Machine Calibration: Regular calibration of injection molding machines ensures accuracy in parameters and prevents defects.

- Ignoring Environmental Factors: Changes in ambient temperature or humidity can affect the process. For example, higher humidity might affect the drying process of raw materials.

- Overlooking Preventive Maintenance: Regular maintenance of machines and molds prevents unexpected downtimes and quality issues.

- Inadequate Training: Operators should be well-trained in understanding and adjusting parameters for different materials and designs.

What are Common Challenges in Setting Injection Molding Parameters?

In the realm of injection molding, certain challenges frequently arise when setting parameters. These challenges can impact product quality and process efficiency.

- Material Behavior Variability: Different materials and even different batches of the same material can exhibit varied behaviors. This variability can affect how materials fill the mold and solidify.

- Mold Design Complexity: Complex molds with intricate designs or varying wall thicknesses pose challenges in ensuring even cooling and pressure distribution.

- Equipment Limitations: Older or less sophisticated equipment may not offer the fine-tuning capabilities required for optimal parameter settings.

- Environmental Changes: Fluctuations in ambient temperature or humidity can affect the process, requiring adjustments in parameters to compensate.

- Operator Skill Level: The skill and experience level of operators play a crucial role. Inexperienced operators may struggle with fine-tuning the parameters for optimal results.

How to Troubleshoot Common Injection Molding Parameter Issues?

Troubleshooting parameter issues in injection molding is essential for maintaining efficiency and product quality. Here is a step-by-step guide to identifying and solving common parameter-related problems.

Step 1: Identify the Issue

- Symptom Recognition: Begin by recognizing the symptoms. For example, short shots indicate insufficient material flow, while warping suggests uneven cooling.

- Record Keeping: Maintain detailed records of process parameters for each production run. This documentation can be invaluable in diagnosing issues.

Step 2: Analyze Possible Causes

- Injection Pressure: Low injection pressure might cause incomplete filling, whereas excessive pressure can lead to flash.

- Mold Temperature: Incorrect mold temperature settings can affect the cooling process, leading to defects like warpage or sink marks.

- Injection Speed: Too fast or too slow injection speeds can cause various defects, such as poor surface finish or air entrapment.

Step 3: Implement Corrective Actions

- Adjust Parameters: Based on the identified issue, adjust relevant parameters. For instance, increase the injection pressure if short shots are a problem.

- Trial Runs: Conduct trial runs with adjusted settings to see if the issue resolves.

Step 4: Monitor and Refine

- Continuous Monitoring: After adjustments, continuously monitor the process to ensure the issue is resolved.

- Feedback Loop: Use feedback from the production floor to make further refinements.

Common Troubleshooting Scenarios

- Short Shots: Increase the injection pressure or the amount of material. Check for any blockages in the material feed system.

- Warping: Optimize cooling time and mold temperature settings. Ensure uniform wall thickness in the mold design.

- Surface Defects: Adjust melt and mold temperatures. Check for moisture in the raw material and ensure proper drying pre-process.

What are Common Challenges in Setting Injection Molding Parameters?

Setting injection molding parameters can be challenging due to various factors:

- Material Variability: Different materials have unique properties requiring specific parameter settings.

- Complex Mold Designs: Complex designs may require special adjustments in pressure and temperature settings.

- Equipment Limitations: Older equipment may not have the precision or control range required for optimal settings.

- Environmental Factors: Changes in ambient conditions can affect the process, requiring adjustments in parameters.

How Do Material Properties Affect Injection Molding Parameters?

The selection of materials in injection molding significantly impacts the setting of process parameters. Each material has unique properties that necessitate specific parameter adjustments for optimal production quality.

Relationship Between Material Choice and Parameter Settings

- Thermal Properties: Materials with different melting temperatures require adjustments in the heating system of the injection molding machine. For example, polypropylene (PP) melts at a lower temperature compared to more heat-resistant polymers like polycarbonate (PC).

- Flow Characteristics: Materials vary in their flow behavior under pressure. Viscous materials may need higher injection pressures compared to more fluidic ones.

- Cooling Rate: Different plastics have varied cooling rates, affecting the cooling time and cycle times. For instance, ABS plastic cools faster than more dense materials like polyethylene (PE).

- Shrinkage and Warpage: Materials with a high shrinkage rate might require longer cooling times and precise mold temperature control to minimize defects.

How Do Different Plastics Behave Under Various Injection Molding Parameters?

Different plastics respond distinctively to parameter changes, making it essential to understand their characteristics for optimal parameter settings.

- Polypropylene (PP): Responds well to a range of temperatures and pressures, making it versatile. However, it can be sensitive to cooling rates, affecting its crystallinity and strength.

- Polycarbonate (PC): Being heat-resistant, it requires higher mold temperatures. Its viscosity also demands higher injection pressures for proper mold filling.

- Acrylonitrile Butadiene Styrene (ABS): Sensitive to rapid changes in temperature, ABS requires a stable and controlled cooling process to maintain surface finish and structural integrity.

- Polyethylene (PE): Exhibits significant shrinkage, necessitating careful control of cooling times and pressures to avoid deformation and ensure uniformity.

What Advanced Techniques Exist in Injection Molding Parameter Control?

The field of injection molding is continually evolving, with advanced techniques emerging for enhanced parameter control. These advancements significantly improve product quality, process efficiency, and the ability to handle complex designs.

Overview of Cutting-Edge Methods and Technologies

- Precision Temperature Control Systems: Advanced systems allow for more accurate control of mold and melt temperatures, essential for complex geometries and high-performance materials.

- Real-Time Monitoring and Automation: Integration of sensors and machine learning algorithms for real-time monitoring and automatic adjustment of parameters to maintain optimal production conditions.

- 3D Printing for Mold Making: Utilizing 3D printing technology for creating molds allows for rapid prototyping and testing, reducing the time and cost involved in mold production.

- Advanced Material Drying Techniques: Implementing sophisticated drying systems that precisely control moisture content in materials, crucial for maintaining material properties and process stability.

Recent Advancements and Their Benefits

- Integration of IoT (Internet of Things): IoT-enabled machines provide comprehensive data collection and analysis, leading to improved process control and predictive maintenance capabilities.

- High-Pressure Injection Molding: This technique allows for faster filling times and improved material flow, particularly beneficial for thin-walled parts.

- Gas-Assisted Injection Molding: Introducing gas into the mold cavity enables the production of parts with hollow sections, reducing weight and material usage.

What are the Future Trends in Injection Molding Parameters?

Looking ahead, the injection molding industry is poised to witness several transformative trends, significantly influencing how parameter control is approached.

Insights into Emerging Trends

- Increased Automation and AI Integration: The use of AI for predictive analysis and automated adjustments is expected to grow, reducing human error and improving consistency.

- Sustainability Practices: As the industry moves towards sustainability, there will be a greater emphasis on using biodegradable materials and recycling processes, which will require adjustments in molding parameters.

- Smart Molds with Embedded Sensors: The development of molds with embedded sensors for real-time data collection on pressure, temperature, and flow rate, enabling more precise control.

How These Trends Might Influence the Industry

- Customization and Flexibility: The ability to quickly adjust parameters for small production runs and custom parts will become increasingly important.

- Energy Efficiency: Advancements in parameter control technologies will contribute to more energy-efficient processes, aligning with global sustainability goals.

- Enhanced Product Quality: Continuous improvements in parameter control will lead to higher quality products with fewer defects.

Conclusion

The world of injection molding is rapidly evolving, with advancements in parameter control techniques playing a pivotal role. These developments not only enhance the capabilities and efficiency of the injection molding process but also pave the way for innovative product designs and sustainable practices.

As the industry continues to embrace these advancements, we can expect to see a significant impact on production quality, environmental sustainability, and the overall landscape of manufacturing.

FAQs

1. What is the typical injection molding pressure?

The typical injection molding pressure ranges from 500 to 1500 bar, varying based on material and part complexity. For example, more viscous materials require higher pressures for effective molding, while intricate designs demand precise pressure control to fill molds properly and prevent defects.

2. What is the minimum precision in injection molding?

The minimum precision in injection molding typically lies between ±0.005 inches (±0.127 mm) to ±0.010 inches (±0.254 mm), depending on machine capabilities and material characteristics. High-grade machines and stable materials can achieve tighter tolerances, essential for precision components.

3. What parameters determine the price of an injection mold?

Several parameters determine the cost of an injection mold:

- Mold Size and Complexity: Larger and more complex molds are more expensive.

- Material: High-quality steel molds cost more but offer better longevity.

- Number of Cavities: More cavities increase the price but improve production efficiency.

- Surface Finish Requirements: Advanced finishes add to the cost.

- Lifespan and Maintenance: Molds for high-volume production with extended lifespans are more costly upfront.