In the realm of manufacturing, injection molding tooling stands as a pivotal process, central to the production and manufacture of countless plastic components. This guide delves into the intricacies of injection molding tooling, unraveling its complexities and highlighting its significance in modern manufacturing.

What is Tooling in Injection Molding?

Injection molding tooling refers to the detailed and sophisticated process of designing and engineering the tools necessary for producing plastic or metal parts via injection molding.

Tooling in injection molding is a multifaceted procedure, encompassing the creation of complex molds that can withstand the rigors of high-volume production.

These molds, typically crafted from robust materials like steel or aluminum, are engineered to endure the high pressures and temperatures involved in the molding process. The design and manufacturing of these molds demand a high level of expertise from tooling engineers, making the tooling process an intersection of art and science.

What are the different types of injection mold tooling?

Injection molding leverages a variety of mold types to cater to diverse manufacturing requirements. Each mold type serves specific purposes, determined by factors such as production volume, part complexity, and material properties.

Here, we delve into the various mold types, their applications, and provide real-life examples to illustrate their utility.

Single-Cavity Mold

A single-cavity mold, as its name suggests, comprises only one cavity, creating a single component in each injection cycle. This simplicity allows for more straightforward design and manufacturing of the mold, which can translate into lower costs and quicker turnaround times.

- Applications: Single-cavity molds are particularly advantageous for custom or specialized projects where production volume is low and each piece may have unique requirements. They’re also ideal for large components, where incorporating multiple cavities in a single mold would be impractical due to size and machine capacity limitations.

- Example: Consider the production of custom automotive dashboards, where each mold is tailored to specific vehicle models. Producing these large, intricate parts individually ensures quality and precision, aligning with the meticulous standards of automotive manufacturing.

Multi-Cavity Mold

Multi-cavity molds consist of multiple cavities of the same design, enabling the simultaneous production of several parts per cycle. This setup significantly increases output, making it fast and highly efficient for mass production. The intricacy in their design lies in ensuring uniform filling, cooling, and ejection for all cavities.

- Applications: These molds are a staple in industries where large quantities of identical parts are required quickly. They’re instrumental in scenarios where time-to-market is critical and large-scale production runs are routine.

- Example: In the pharmaceutical industry, producing millions of identical medicine bottle caps is a typical application. The high demand and standardized nature of these caps make multi-cavity molds a logical choice to ensure consistent production at scale.

Family Mold

Family molds produce multiple, distinct parts within a single mold cycle. The challenge with family molds lies in the design complexity, as each cavity can have different volumes, which necessitates careful balancing of the mold to ensure quality and consistency across all parts.

- Applications: This mold type is particularly useful when manufacturing parts that go together in a final product, especially when these components are required in similar quantities. It reduces the need for multiple molds and streamlines the manufacturing process.

- Example: A practical application is found in consumer electronics, such as creating the various plastic components of a remote control — buttons, battery cover, and casing — all within a single mold cycle. This efficiency in production is crucial in an industry where speed and precision are paramount.

Insert Mold

- Description: Insert molding is an advanced technique where a pre-fabricated insert, typically made of metal, is placed into the mold before the injection of plastic. This process allows the melding of the plastic material with the insert, creating a single, integral piece. The precision in the placement of the insert and the timing of the injection are critical to ensure a strong bond between the components.

- Applications: Insert molding is widely used in applications where the robustness and functionality of metal are required along with the design flexibility of plastic. It is highly favored in the production of electrical components, medical devices, and automotive parts where strong, durable bonding between different materials is crucial.

- Example: In the electronics industry, insert molding is employed to produce complex parts like connectors with metal pins or contacts integrally molded into a plastic housing. This method ensures robust electrical connectivity while providing the necessary insulation and mechanical support.

Overmolding Mold

Overmolding involves the sequential injection of different materials to create a single part with multiple layers. The first material forms the substrate, which is then overlaid with another material during a subsequent molding cycle. This process is often used to add soft-touch surfaces or to create parts with multiple colors or textures.

- Applications: Overmolding is ideal for enhancing the aesthetic and functional aspects of a part, such as adding ergonomic grips to hand tools or protective outer layers to electronic devices. It is also used in consumer products to achieve a combination of hard and soft textures for improved usability.

- Example: In tool manufacturing, overmolding is used to create hand tools with a rigid core and a soft, grippy outer layer. This technique not only improves the tool’s ergonomics but also its aesthetic appeal, making it a popular choice in the competitive consumer market.

Prototype Mold

Prototype molds are less complex and more cost-effective options than production molds and are used primarily for producing a limited number of parts. This allows designers and engineers to evaluate and understand the design, fit, function, and feasibility of a part before committing to the expense of a full-production mold. These molds are typically made from less durable materials and are not intended for long-term use.

- Applications: Essential in the product development phase, prototype molds are used across industries for testing and validating product designs. They are particularly valuable in industries such as consumer electronics, automotive, and medical devices, where design accuracy and functionality are paramount.

- Example: In the development of medical devices, prototype molds might be used to create components for a new surgical tool, allowing for rigorous testing and evaluation in real-world scenarios before the design is finalized for mass production.

Stack Mold

Stack molds are a highly efficient form of molding that multiplies the output capacity of a conventional single-face mold. They consist of multiple mold parting surfaces or ‘stacks’, each producing a part. This configuration effectively doubles or even triples the output without increasing the machine size or clamp requirements.

- Applications: These molds are particularly beneficial for large-volume production where space and machine size constraints exist. They are commonly used in industries where high-volume parts with relatively small sizes, like packaging or disposable medical supplies, are produced.

- Example: In the packaging industry, stack molds are frequently used for the mass production of disposable food containers. This method maximizes production efficiency, allowing manufacturers to rapidly produce high quantities of containers while optimizing factory floor space.

What are the different components and features of injection molding tooling?

Mold Cavity

The mold cavity is the hollow space in an injection mold where molten plastic is injected and shaped. It’s the heart of the mold, determining the shape and size of the final plastic part. The design of the mold cavity is paramount, as it directly affects the quality and properties of the molded part.

How it Works and Its Importance:

- The mold cavity is where the plastic resin transforms into its final form. The molten plastic is injected under high pressure into the cavity, where it cools and solidifies.

- Its design dictates the surface finish, dimensional accuracy, and overall aesthetic of the plastic part.

- The mold cavity must be precisely engineered to accommodate the shrinkage of plastic and ensure the ejection of the part without defects.

Different Types and Approaches:

- Single-cavity molds for low-volume manufacturing or prototyping.

- Multi-cavity molds for high-volume production, where multiple parts are produced in a single cycle.

- Family molds where different parts of an assembly are molded simultaneously.

Mold Core

The mold core forms the internal surfaces of a plastic part. It is often a protruding section in the mold that creates hollows, channels, or other internal features in the molded part.

How it Works and Its Importance:

- The core works in tandem with the mold cavity. As the molten plastic fills the cavity, the core shapes the internal features.

- It is crucial for creating complex internal geometries and is integral to the functionality and strength of the part.

- The core must be precisely machined and aligned with the cavity to ensure seamless part formation and easy ejection.

Different Types and Approaches:

- Fixed cores for simple internal geometries.

- Sliding or collapsible cores for complex internal features that would be impossible to demold with a fixed core.

- Interchangeable cores for versatility in producing parts with varying internal designs using the same mold.

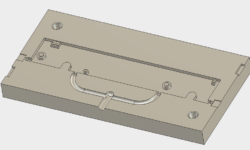

Runner System

The runner system in injection molding is a network of channels that guides molten plastic from the injection molding machine’s nozzle to the mold cavities.

How it Works and Its Importance:

- The runner system ensures optimum flow of plastic, facilitating even filling of the cavities.

- It plays a critical role in the quality of the part, as a poorly designed runner system can lead to defects like warpage or sink marks.

- The system must balance the flow path lengths to all cavities to ensure uniform part quality.

Different Types and Approaches:

- Cold runner systems, where the runners solidify along with the part and are ejected.

- Hot runner systems, which maintain the plastic in a molten state within the runners, leading to reduced waste and faster cycle times.

Channel

Channels in a mold refer to the pathways within the runner system that direct the molten plastic to various parts of the mold.

How it Works and Its Importance:

- Channels are designed to ensure the efficient flow of plastic, minimizing pressure loss and material degradation.

- They are critical for maintaining the integrity of the plastic, preventing issues like premature cooling or overheating.

- Optimized channel design is essential for achieving uniform wall thickness and reducing material usage.

Different Types and Approaches:

- Straight channels for simpler molds.

- Curved or branched channels for complex molds requiring intricate flow paths.

- Gate channels that control the entry point of plastic into the cavity, impacting the part’s aesthetic and structural properties.

Gate

The gate in injection molding tooling is a critical passage through which molten plastic enters the mold cavity. It’s not just a mere opening; it’s a meticulously designed feature that significantly impacts the flow and quality of the plastic part being molded.

Function and Importance:

- The gate serves as the entry point for molten plastic, playing a pivotal role in the distribution and pressure of the material within the mold.

- A well-designed gate ensures uniform filling of the mold, minimizes material stress, and contributes to the structural integrity and aesthetic quality of the final product.

- The gate’s size and placement are crucial; incorrect specifications can lead to defects like warping, sink marks, or incomplete filling.

Types and Approaches:

- Edge gates are commonly used for rectangular or flat parts.

- Tab gates help in reducing the stress on the part during ejection.

- Submarine gates are hidden beneath the part’s surface and are ideal for aesthetic purposes.

- Hot tip gates are used in hot runner systems, providing a direct flow path for the molten plastic.

Ejector System

The ejector system in injection molding tooling is the mechanism responsible for removing the solidified plastic part from the mold. This system is not only about ejection but also about precision and care to ensure the integrity of the molded part.

Function and Importance:

- Ejector pins within the system push the cooled part out of the mold cavity, a step crucial for continuous production.

- The system’s design must ensure smooth, even ejection to prevent damage or deformation to the part.

- Proper placement and number of ejector pins are essential for balancing the force applied on the part, especially important in complex and delicate parts.

Types and Approaches:

- Single-action ejector systems are used for simpler molds.

- Complex molds might require multiple ejector pins or a stripper plate mechanism for uniform force distribution.

- Some systems use air or hydraulic mechanisms for specialized ejection requirements.

Cooling System

The cooling system in injection molding tooling is an array of channels designed to regulate the temperature of the mold and the solidifying plastic part. Effective cooling is indispensable for quality and efficiency in the injection molding process.

Function and Importance:

- Cooling lines circulate a coolant, typically water or oil, to absorb heat from the mold, thereby cooling the molten plastic quickly and uniformly.

- Efficient cooling reduces cycle time, enhances part quality, and prevents defects like shrinkage or warping.

- The design of the cooling system must ensure consistent temperature distribution across the mold surface.

Types and Approaches:

- Conventional cooling systems with straight-line channels are the most common.

- Bubblers and baffles are used for deeper or thicker parts, where direct cooling line contact is limited.

- Advanced mold cooling technologies employ conformal cooling lines, which follow the contour of the mold for more efficient cooling.

Alignment and Mounting Features

Alignment and mounting features in injection molding tooling are fundamental to the accurate and secure placement of the mold within the injection molding machine. These features are essential for precision, repeatability, and safety in the molding process.

Function and Importance:

- Alignment features, such as guide pins and bushings, ensure the mold halves align correctly every time the mold closes.

- Mounting features, like clamps and bolts, secure the mold to the injection molding machine, providing stability and safety during high-pressure injection.

- Accurate alignment and secure mounting are vital to prevent flash, misalignment of the mold halves, and damage to the mold or machine.

Types and Approaches:

- Standard guide pins and bushing systems are used for most applications.

- Magnetic and hydraulic clamping systems offer quick mold change capabilities for high-mix, low-volume manufacturing environments.

- Specialized alignment systems may be employed for molds with unconventional designs or extremely tight tolerances.

Venting

Venting in injection molding tooling is a crucial yet often overlooked component. It refers to the process or feature within the mold that allows air and gases to escape during the injection of molten plastic.

Function and Importance:

- Venting is vital to prevent air traps and gas burns, which can mar the surface of the molded part.

- It ensures the molten plastic fills the mold cavity completely and evenly, critical for achieving dimensional accuracy and surface quality.

- Proper venting contributes significantly to the overall efficiency of the molding process, reducing defects and enhancing the quality of the final product.

Types and Approaches:

- Vent holes or channels that allow air to escape from the mold cavity.

- Porous materials in specific mold areas can also be used to enable gas escape.

- Venting can be carefully controlled and optimized depending on the material and the design of the part.

Slide and Lifter Mechanisms

Slide and lifter mechanisms are integral to injection molds, designed to create complex and undercuts in molded parts.

Function and Importance:

- These mechanisms enable the molding of parts with intricate geometries and features that are not possible with simple open and shut molds.

- They are crucial for ensuring the efficient ejection of complex parts without causing damage or distortion.

- Slides and lifters contribute to the versatility of the mold, allowing the creation of more complex and varied designs.

Types and Approaches:

- Angular slides that move at an angle to the mold opening.

- Lifters, which are used to create recessed features by moving perpendicular to the mold opening.

- Hydraulic or mechanical actuation methods, each offering different benefits in terms of control and force application.

Mold Materials

Mold materials in injection molding are pivotal, as they directly affect and improve the tooling’s performance, durability, and the quality of the molded parts.

Function and Importance:

- The choice of material impacts the mold’s wear resistance, thermal conductivity, and ability to withstand high pressure and temperatures.

- It determines the mold’s lifespan and the ability to produce consistent, high-quality parts over hundreds of thousands of cycles.

- Selecting the appropriate mold material is crucial for optimizing the manufacturing process and balancing cost-efficiency with performance.

Types and Approaches:

- Steel molds, preferred for high-volume production due to their durability and long lifespan.

- Aluminum molds, which are more cost-effective and suitable for prototyping or low-volume manufacturing.

- Specialty alloys and coatings can be used to enhance certain properties like wear resistance or reduce sticking.

Inserts

Inserts in injection molding are components placed into the mold to form part of the cavity and are essential for creating specific features in the molded part.

Function and Importance:

- Inserts are used to create features such as threads, undercuts, or to introduce different materials into a single molded part.

- They enhance the mold’s flexibility, allowing the production of complex parts with varied features without designing a new mold.

- Inserts can be interchangeable, providing the flexibility to produce different variants of a part from the same mold.

Types and Approaches:

- Metal inserts for high-strength features like threads or bearing surfaces.

- Interchangeable inserts that allow for quick modification of the mold for different part designs.

- Inserts made from different materials like plastic or metal, depending on the required properties of the final part.

Cavity Inserts

Cavity inserts are specialized components used in injection molds to create specific features or geometries in the molded plastic parts.

Function and Importance:

- These inserts are essential for introducing intricate details, textures, or complex shapes that are not directly part of the mold’s primary structure.

- They provide flexibility in mold design, allowing for easy modification of the mold cavity for different part designs.

- Cavity inserts are crucial for enhancing product customization while maintaining cost-effectiveness and efficiency in the manufacturing process.

Types and Approaches:

- Interchangeable inserts for molds that produce various versions of a part.

- Textured inserts for adding specific surface finishes to the molded part.

- Custom-designed inserts for creating unique geometrical features that are otherwise difficult to mold.

Mold Inserts

Mold inserts are modular parts of the mold that can be easily replaced or altered, providing versatility and adaptability in the molding process.

Function and Importance:

- They allow for quick changes in the mold design without the need for a complete mold overhaul, significantly reducing downtime and cost.

- Mold inserts are essential for accommodating variations in part design, such as different logos, textures, or geometrical changes.

- Their use enhances the overall lifespan of the mold by allowing worn or damaged sections to be replaced independently.

Types and Approaches:

- Interchangeable inserts for varying part designs or features.

- Wear-resistant inserts in high-wear areas to prolong mold life.

- Custom inserts tailored to specific product requirements or unique design features.

Lifters

Lifters are integral components in injection molding tooling, designed to create angled undercuts or complex features in molded parts that cannot be achieved with standard mold designs.

Function and Importance:

- Lifters enable the molding of intricate designs by allowing the creation of features that are not aligned with the mold opening direction.

- They are pivotal for enhancing the design flexibility of molds, allowing for the production of more complex parts without the need for additional tooling.

- The precise design and operation of lifters are crucial for ensuring the integrity and quality of the final molded part.

Types and Approaches:

- Standard lifters are commonly used for simple angled undercuts.

- Complex lifters with multiple movements or unique geometries for more intricate parts.

- The design and placement of lifters vary based on the part geometry and the specific requirements of the molding process.

Runners

Runners in injection molding tooling are the channels through which the molten plastic travels from the injection molding machine to the mold cavities.

Function and Importance:

- Runners play a crucial role in the distribution of molten plastic, ensuring it reaches all parts of the mold evenly and quickly.

- The design of the runner system affects the overall efficiency of the molding process, impacting factors like cycle time and material usage.

- Properly designed runners are essential for achieving consistent quality across all parts and minimizing material wastage.

Types and Approaches:

- Sprue, runner, and gate systems are the typical components of a runner system.

- Balanced runner systems ensure even flow to all cavities, while unbalanced systems may be used for molds with varying cavity sizes.

- The size and shape of runners are tailored based on the part design, material, and specific process requirements.

Hot Runners

Hot runners in injection molding are advanced runner systems that maintain the molten state of the plastic within the runner, eliminating solidification within these channels.

Function and Importance:

- Hot runners are crucial for reducing material waste, as they eliminate the need to regrind and recycle runners.

- They provide better control over the flow and temperature of the plastic, leading to higher-quality parts and faster cycle times.

- Hot runner systems are ideal for large-scale production where efficiency and material savings are critical.

Types and Approaches:

- Internally heated runners where heat is applied from within to maintain the plastic’s temperature.

- Externally heated runners that use heating elements around the runner channels.

- Different types of hot runner nozzles and gates, each tailored for specific applications and materials.

Cold Runners

Cold runners are the more traditional runner systems in injection molding, where the plastic in the runners solidifies along with the part.

Function and Importance:

- Cold runners are simpler and more cost-effective than hot runners, making them suitable for smaller-scale productions or simpler part geometries.

- They are easier to design and maintain, offering flexibility in material changes.

- However, cold runners require the regrinding and recycling of the runner material, which can increase cycle time and material costs.

Types and Approaches:

- Two-plate and three-plate designs, with variations in runner layout and gating methods.

- Submarine gates and edge gates are common in cold runner systems.

- The design is often based on the ease of runner removal and material efficiency.

Core Pins

Core pins are slender, rod-like components used in injection molding to create holes, channels, or internal cavities within molded parts.

Function and Importance:

- Core pins are instrumental in forming internal features of a part that cannot be directly created by the mold cavity.

- They play a critical role in achieving the desired internal geometry of the part, essential for both aesthetic and functional purposes.

- The precision and quality of core pins directly impact the accuracy and consistency of the internal features of the molded parts.

Types and Approaches:

- Standard core pins for creating simple holes or channels.

- Complex core pins with varying diameters or shapes for intricate internal geometries.

- Cooling or heated core pins that aid in controlling the temperature within the mold for specific material requirements.

Baffles and Diffusers

Baffles and diffusers are components within the cooling system of an injection mold, designed to optimize the flow of coolant.

Function and Importance:

- These elements ensure uniform cooling throughout the mold, which is vital for maintaining part quality and reducing cycle times.

- Baffles direct the coolant flow in a specific pattern, enhancing the cooling efficiency in targeted areas of the mold.

- Diffusers spread the coolant evenly across a broader area, ensuring consistent temperature distribution and preventing defects like warping and shrinkage.

Types and Approaches:

- Straight or angled baffles for directing coolant flow in specific directions.

- Perforated or slotted diffusers for even distribution of coolant across larger mold areas.

- Custom-designed baffles and diffusers for molds with complex geometries or specific cooling requirements.

Water Manifold

The water manifold in injection molding tooling is a critical component for managing the cooling system of the mold. It functions as a distribution hub for coolant, directing it to various parts of the mold.

Function and Importance:

- The water manifold ensures uniform and efficient cooling of the mold, which is essential for maintaining consistent quality in the molded parts.

- Proper cooling impacts the cycle time and the overall productivity of the molding process.

- The design and efficiency of the water manifold directly influence the lifespan of the mold and the quality of the final product.

Types and Approaches:

- Custom-designed manifolds tailored to specific mold configurations.

- Modular manifolds that allow for flexibility and adaptability in cooling different molds.

- Advanced manifolds with integrated temperature and flow controls for precise cooling management.

Mold Texture

Mold texture refers to the surface finish or pattern imparted to the surface of the molded part, which is achieved through the texture of the mold cavity.

Function and Importance:

- Texturing enhances the aesthetic appeal of the plastic part and can also provide functional attributes like improved grip or reduced light reflection.

- The choice of texture impacts the release of the part from the mold and can influence the overall molding process.

- Texturing can range from simple matte finishes to complex, detailed patterns, depending on the product requirements.

Types and Approaches:

- Chemical etching, where acid is used to create textures on the mold surface.

- Laser texturing, offering high precision and intricate pattern capabilities.

- Mechanical methods like bead blasting or sanding for simpler textures.

Sprue Bush

The sprue bush is a component of injection molds that guides the molten plastic from the injection nozzle into the mold.

Function and Importance:

- It is a crucial element in the mold as it forms the primary passage for the plastic, impacting the flow and pressure of the material entering the mold.

- The design and quality of the sprue bush are vital for preventing leaks and ensuring a smooth transition of the plastic into the mold.

- Properly designed sprue bush contributes to efficient molding cycles and reduces material wastage.

Types and Approaches:

- Standard sprue bushes for general applications.

- Custom-designed sprue bushes for specific material properties or injection pressures.

- Sprue bushes with advanced coatings for wear resistance and improved material flow.

Cavity Retaining Plate

The cavity retaining plate in injection molding tooling holds and supports the mold cavity inserts, ensuring their precise alignment and secure placement within the mold.

Function and Importance:

- This plate is essential for maintaining the integrity of the mold cavity, directly impacting the accuracy and quality of the molded part.

- It helps in evenly distributing the injection pressure and supports the cooling system of the mold.

- The design and strength of the cavity retaining plate are critical for the durability and functionality of the mold.

Types and Approaches:

- Plates designed for easy insert replacement and maintenance.

- High-strength materials to withstand high-pressure injection molding conditions.

- Customized plates for specific mold designs or unique cavity configurations.

What is the difference between hard and soft injection mold tooling?

Hard and soft injection mold tooling are two distinct approaches in the fabrication of molds used in the injection molding process. Understanding their differences is crucial for choosing the appropriate tooling for specific production needs.

Hard Tooling:

- Description: Hard tooling, typically made from hardened steel, is used for high-volume production runs.

- Function and Importance: The robustness of hard tooling allows it to withstand the high pressures and temperatures of the injection molding process over many cycles, making it ideal for mass production.

- Different Types and Approaches: Varying grades of steel are used, with some being treated for additional wear resistance. The design complexity can be higher in hard tooling, given its longevity.

Soft Tooling:

- Description: Soft tooling is often made from aluminum or pre-hardened steel and is used for prototyping or low-volume production.

- Function and Importance: This type of tooling is easier and faster to produce but is not as durable as hard tooling, making it suitable for shorter production runs.

- Different Types and Approaches: Aluminum molds offer faster cooling times and quicker turnaround but are less durable than their steel counterparts.

What kind of tooling is used in metal injection molding?

Metal injection molding (MIM)is a process that combines the versatility of plastic injection molding with the strength and integrity of metal. The tooling used in MIM must accommodate the unique properties of metal powders and the binder material.

- Tooling Material: High-grade steel is commonly used for MIM tooling to withstand the high temperatures and pressures involved in molding metal powders.

- Design Considerations: MIM tooling often requires tighter tolerances and more precise machining than plastic injection molds due to the shrinkage characteristics of metal during the sintering process.

- Special Features: Advanced features such as specialized ejection systems and temperature control units are often incorporated into MIM tooling to manage the complexities of metal parts.

How Has Injection Molding Tooling Evolved Over Time?

Injection molding tooling has seen significant advancements over the years, driven by the demands for more complex parts, greater efficiency, and technological innovations.

- Early Developments: Initially, molds were simplistic and manually operated, suitable for basic parts with less complexity.

- Technological Integration: With the advent of computer-aided design (CAD) and computer-aided manufacturing (CAM), tooling became more sophisticated, allowing for intricate designs and tighter tolerances.

- Materials and Techniques: The introduction of new materials like advanced alloys and coatings, along with techniques like 3D printing for prototype tooling, has further expanded the capabilities of injection molding.

- Automation and Smart Features: Modern tooling incorporates automated systems and sensors for real-time monitoring and control, enhancing precision and reducing cycle times.

How Do Tooling Complexity and Tight Tolerances Interact in Injection Molding?

In the realm of injection molding, the interplay between tooling complexity and tight tolerances is a pivotal aspect that dictates the success of the manufacturing process. This relationship is crucial in producing high-quality, precision parts.

Tooling Complexity

Tooling complexity refers to the intricacy of the mold’s design, including the number of cavities, the sophistication of the parts it must create, and the intricacies involved in the mold’s own construction.

- Impact on Tolerances: As complexity increases, maintaining tight tolerances becomes more challenging. Complex molds with intricate details require precision engineering to ensure that each part produced meets stringent specifications.

- Approaches: Advanced CAD/CAM software, high-precision machining, and sophisticated design techniques are employed to manage this complexity while still adhering to tight tolerances.

Tight Tolerances

Tight tolerances refer to the narrow margin of error allowable in the dimensions of the molded parts.

- Importance: Adhering to tight tolerances is essential in industries where precision is paramount, such as aerospace, medical, and automotive sectors.

- Achieving Tight Tolerances: This requires high-quality tooling materials, precision machining, and state-of-the-art molding machines. It also involves meticulous planning and control of the molding process, including temperature, pressure, and cooling rates.

Why are Sensors, Benchmarking, and Process Repeatability Critical in Injection Molding Tooling?

The use of sensors, benchmarking, and process repeatability are key factors in ensuring the quality and efficiency of injection molding tooling. These elements play a critical role in maintaining consistency, reducing errors, and enhancing overall production quality.

Sensors:

- Role: Sensors in injection molding tooling provide real-time data on various aspects of the molding process, including temperature, pressure, and flow rate.

- Importance: This information is vital for maintaining process control, detecting potential issues early, and ensuring that the molded parts meet the required specifications.

Benchmarking:

- Definition: Benchmarking in injection molding involves setting standards or key performance indicators for the molding process.

- Purpose: It helps in comparing actual performance against these standards, ensuring consistent quality, and identifying areas for improvement.

Process Repeatability:

- Explanation: Process repeatability refers to the ability to replicate the molding process consistently over time, producing parts that are uniform in quality and dimensions.

- Significance: High repeatability is essential for large-scale production runs where consistency across thousands or millions of parts is critical. It reduces waste, improves efficiency, and ensures customer satisfaction.

What materials are used in injection molding tooling?

In injection molding tooling, the choice of materials is pivotal, influencing the durability, cost, and performance of the mold. Various materials are used based on the requirements of the specific molding application.

- Steel: High-grade steel is a popular choice for its durability and wear resistance, ideal for high-volume production. It includes types like stainless steel, P20, and H13.

- Aluminum: Known for its lightweight and quicker heating and cooling properties, aluminum is often used for prototype tools or low-volume production.

- Beryllium-Copper Alloys: Used in areas of the mold requiring rapid heat removal or in parts of the mold with intricate geometries.

- Pre-Hardened Steel: A cost-effective option used in less demanding applications; it doesn’t require additional heat treatment.

- Tool Steel: For high-wear applications, tool steels like D2 or A2 are used, offering robustness and longevity.

- Nickel-Based Alloys: Used for their high-temperature resistance in applications like insert molding.

How Does Material Flow Impact Tooling in Injection Molding?

Material flow characteristics are a critical factor in mold design and directly influence product quality. Understanding how different materials behave during the injection molding process is crucial for creating effective molds.

- Material Viscosity: Low-viscosity materials flow easily and are suitable for intricate molds, while high-viscosity materials require more robust and simple designs.

- Cooling Characteristics: Materials that cool rapidly may require molds with advanced cooling systems to prevent defects like warping or sink marks.

- Flow Rate and Pressure: The ability of the material to fill the mold under certain pressures and flow rates impacts the mold design, especially the gate and runner systems.

- Shrinkage and Warping: Material properties like shrinkage rate must be considered in the mold design to ensure dimensional accuracy of the final product.

How to Choose the Right Tooling Material for Your Project?

Selecting the appropriate tooling material is a critical decision in the injection molding process. It depends on various factors including production run volume, part complexity, and material properties.

- Production Volume: High-volume runs demand durable materials like hardened steel, while aluminum or pre-hardened steel can be suitable for lower volumes.

- Part Complexity: Complex parts with intricate details often require high-grade steel for precision, whereas simpler designs can be accommodated with less expensive materials.

- Mold Lifetime: For molds expected to last for millions of cycles, materials like tool steel or nickel-based alloys are preferred.

- Cost Considerations: Budget constraints may lead to choosing more cost-effective materials like aluminum or pre-hardened steel, but the trade-off in durability and precision should be considered.

- Thermal Conductivity: Materials with high thermal conductivity, like aluminum, are chosen for molds requiring quick heating and cooling cycles.

- Surface Finish Requirements: For high-quality surface finishes, tool steel with specific treatments might be required.

- Compatibility with Molding Material: The chemical and thermal compatibility of the mold material with the plastic being molded is crucial to prevent issues like corrosion or degradation.

What are the Common Issues in Injection Molding Tooling and How to Troubleshoot Them?

Injection molding tooling can encounter various problems that affect the quality of the molded parts. Recognizing and troubleshooting these issues is key to maintaining efficient production.

- Flash Formation: Caused by excessive pressure or misaligned mold parts. Solution involves adjusting pressure and ensuring proper alignment.

- Short Shots: Occur when the mold is not filled completely. Can be addressed by increasing the material flow or adjusting the temperature.

- Warping: Happens due to uneven cooling. The solution is to optimize the cooling system and ensure uniform temperature distribution.

- Surface Defects: Can be caused by poor material quality or improper mold temperature. Solution involves using high-quality materials and adjusting the temperature settings.

How to Optimize Costs in Injection Molding Tooling?

Cost optimization in injection molding tooling is essential for maintaining a balance between quality, efficiency, and budget. There are several strategies to achieve this:

- Material Selection: Use cost-effective materials that still meet the durability and quality requirements. For example, opting for aluminum or pre-hardened steel for lower volume projects.

- Design Efficiency: Simplify the mold design to reduce complexity and machining time without compromising on the part’s functionality.

- Utilize Advanced CAD/CAM Systems: These systems can help optimize the mold design for material and time efficiency.

- Regular Maintenance: Proactive and regular maintenance of the tooling can significantly extend its life, thereby reducing the need for frequent replacements.

- Modular Design: Implementing a modular approach in tooling design allows for the easy replacement of worn-out parts instead of the entire tool.

- Invest in Quality: Initially investing in high-quality tooling can reduce the cost over time due to less frequent repairs and maintenance.

- Process Optimization: Streamlining the injection molding process can reduce cycle times and energy consumption, leading to cost savings.

Conclusion

Injection molding tooling encompasses a wide array of practices and considerations, from understanding the interplay between material properties and mold design to optimizing the costs involved in the tooling process.

The key to success in injection molding lies in the meticulous attention to detail, understanding the complexities of the process, and continually adapting to technological advancements.

This comprehensive approach ensures the production of high-quality parts while maintaining efficiency and cost-effectiveness.