Welcome to 3ERP's blog

We share information, tips and things we've learned from our years in the rapid prototyping and manufacturing industry.

Coextrusion or co-extrusion is a plastic manufacturing process that uses two or more extruders to make a single extrusion. It is used to make extrusions with the material properties of two different plastics. The coextrusion process is used in the production of films, multilayer tubing, food packaging, and other applications where a combination of polymers […]

The injection molding process is ideal for making large batches of identical colored parts. Because pigments can be mixed into the molding material prior to production, there is generally no need for secondary finishing processes like painting or plating. Furthermore, the color goes through the entire part, not just the surface layer, so parts retain […]

Regularly used for professional or industrial plastic prototypes, the process of urethane casting is also a godsend for hobbyists who want to make small plastic miniatures, models, toys, and figurines. With a good level of detail and very low up-front costs compared to injection molding, urethane casting could be your next solution for tabletop gaming […]

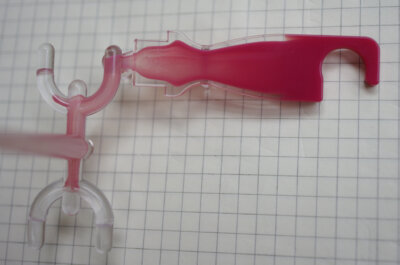

Engineers often require different material properties across different regions of a part, and they can achieve this goal in various ways. Often, parts will be designed as separate components that can be assembled using glue or fasteners. One component of the assembly may be made from a soft, pliable material, while another might be made […]

In the realm of manufacturing, particularly in the plastics industry, the durability and longevity of injection molds are pivotal for efficient production. Understanding the life expectancy of these molds is not just about numbers; it’s about grasping the intricate dance of material, design, and maintenance that dictates their lifespan. This article dives deep into the […]

The world of manufacturing was forever changed with the advent of injection molding, a groundbreaking technique crucial in shaping today’s plastic production landscape. This article delves into the rich history and transformative impact of injection molding, tracing its roots and exploring its pivotal role in the modern plastics industry. What Is Injection Molding? Injection molding […]

In the realm of manufacturing, injection molding tooling stands as a pivotal process, central to the production and manufacture of countless plastic components. This guide delves into the intricacies of injection molding tooling, unraveling its complexities and highlighting its significance in modern manufacturing. What is Tooling in Injection Molding? Injection molding tooling refers to […]

In the realm of modern manufacturing, CNC machining emerges not just as a method, but as a monumental shift in production philosophy. This technology, marrying the precision of computer algorithms with the robustness of machine tools, has not just enhanced but redefined the parameters of production. From its nascent sketches on paper to its current […]

Many injection molding parts are made using single-cavity tooling. That is, each mold core and cavity is designed to produce a single component for each shot of molten plastic. But this doesn’t have to be the case. Some molds contain multiple cavities, which means that multiple components can be formed with each shot of plastic. […]

Thanks to its material versatility and efficiency, injection molding is the most widely used manufacturing process for plastic parts. It is most commonly used to process thermoplastic polymers, but can also be used for thermosets and elastomers. Injection molding is also one of the best manufacturing processes for processing polymer blends. Polymer blends are mixtures […]