With more than 10 years in the rapid manufacturing business, 3ERP has built up rich experience in CNC machining parts for both prototyping and mass production.

In any form of manufacturing, machining tolerances play a crucial role as they define the allowable variation in dimensions and physical properties of a manufactured part. Maintaining tight tolerances is vital to ensure the accuracy, performance, and reliability of a product. Particularly

In this article, we explain how we can achieve tight tolerances on CNC machined parts.

We hope it’s useful for CNC machine shops and anyone who might be curious about how these things work.

What are tight machining tolerances?

Tight tolerances in CNC machining refer to the degree of precision and accuracy required in the production of a part or component. In CNC machining, tight tolerances are often required for parts that need to fit together precisely, have smooth surfaces, or meet specific performance requirements.

Tight tolerances can be challenging to achieve and may require specialized expertise, equipment, and materials, but they are critical for producing high-quality, reliable parts that meet the exacting standards of many industries.

What is considered tight machining tolerance?

Tight tolerance in CNC machining is typically considered to be in the range of +/- 0.005 mm to +/- 0.025 mm (or +/- 0.0002 in to +/- 0.001 in), depending on the specific application and the requirements of the part being machined.

However, this can vary based on the material being machined, the size of the part, and other factors. It’s always important to communicate your specific tolerance requirements with your CNC machining provider to ensure that the finished parts meet your needs.

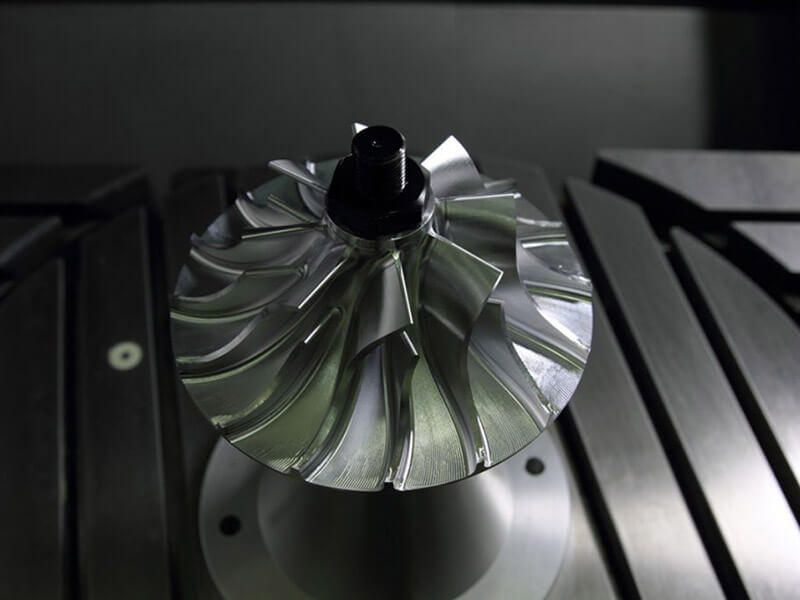

How to make tight tolerance CNC Machining Parts?

To achieve tight tolerances, CNC machines use advanced computer programming and cutting tools with high accuracy and precision. The machining process is carefully controlled, and measurements are taken regularly to ensure that the finished part meets the required specifications.

Let’s dive into our tips on how to achieve tight tolerances for your CNC machined parts.

1. Find the right workplace

When looking for a workshop, you can’t focus only on the neighborhood; you also need to consider what floor you’ll be on. In our experience, the first floor (ground floor) is the only option. I have visited lots of CNC shops located on the second floor, third floor or even higher — usually because it is cheaper to rent. But the extra vibration on these levels can cause lots of problems. When the CNC machines are running, you can feel that vibration, and it is virtually impossible to make precision CNC parts in a trembling workshop.

Our CNC Machining Workshop

2. Control workshop temperature

Workshop temperature is another very important factor when making precise parts. Between day and night, temperatures in the workshop can vary by more than 10 degrees Celsius, and you can’t expect a consistent tolerance when there is such significant variation. That’s why we installed air conditioning in the workshop. Over 90% of companies in China don’t have air conditioning in their workshop to stabilize temperatures, even though it can hit 40 degrees during summer. Staff will obviously struggle to concentrate and stay calm in such an environment, and they’ll end up making mistakes.

3. Use quality CNC machines

Machining tolerances are one of the most important factors for ensuring part quality. If the machine tolerance is +/-0.02 mm, how can you guarantee +/-0.01 mm of tolerance? Although human knowhow plays a big role in making precision machined parts, it’s true that a workman is only as good as his tools, so we are always happy to invest in our machining centers. That being said, the most elaborate and versatile machining centers are not always the most accurate.

4. Balance tool holders

There are lots of tool holders available in the market, with prices ranging from 30 to 500 USD, and the dynamic balance of the tool holder is very important for accurate machining. Unbalance can be caused by misalignment, asymmetrical rotor design, concentricity errors and other factors, and it can lead to less accurate parts. In general, highly unbalanced tool holders should be balanced by using a professional balancing service, but some holders are designed for easy adjustment via the addition of weighted rings that can offset the unbalance. From our previous testing, a low-quality tool holder might cause 0.02 mm or more of jitter, while the maximum value of a good one is under 0.005 mm. We recommend using heat shrink tool holders from MST or Haimer.

Precision Heat Shrink Tool Holder

5. Use (the correct) sharp cutting tools

The quality and sharpness of cutting tools plays a big role in achieving tight tolerances. Dull tools not only drain your machine of energy, they also prevent you from achieving accuracy and precision, since the dulled tip of the cutting tool has a larger radius than a sharp tip. Shallow cuts are also hard to achieve, since the blunt tool may not catch the surface of the workpiece during a pass, instead simply bouncing off. When machining materials with a low melting point, dull tools can also cause surface deformations due to heat buildup. We take care to maintain proper tool condition, and we also have expertise in tool selection: after all, you can’t achieve tight tolerances on fine features with a roughing end mill. Learn more about cutting tools

6. Use good material suppliers

It’s easier to achieve a tight tolerance on a machinable material like an aluminum alloy, but different material suppliers can provide vastly different versions of the same grade of metal. Many suppliers provide certifications with their materials, showing that samples of the metal have passed a test proving their composition, but certifications only tell half the story. For instance, a bar of aluminum 6082 with a perfect ratio of silicon, magnesium and manganese may still produce horrible results if it has been subject to improper heat treatment. We’ve built up relationships with a reliable group of suppliers over time, but finding such suppliers naturally involves some trial and error.

7. Deploy an on-machine inspection system

Inspection of finished parts is an important part of quality control, but a better way to guarantee tight tolerances is to use an on-machine inspection system, consisting of a small probe that checks machining accuracy during a job. We use high-end Renishaw inspection systems on several of our CNC machines, and these inspection systems can accurately measure part dimensions during machining in addition to providing automatic offset correction.

8. Other considerations

- Workshop operating system: Using a centralized machine shop management system means you won’t be rushing jobs, allowing you to machine with care and precision.

- Experienced engineers: Experienced engineers know how to modify designs for simple and accurate machining that will produce better results. Experienced engineers know which is the best way to make a part as soon as they have CAD file and tolerance required. First of all, we decide how to hold the workpiece. (Read more about different ways of holding workpieces.) Then, we create the tool paths. An experienced engineer will consider both efficiency and tolerance. For example, some engineers may spend hours making a part, while someone could make the same part in an hour by optimizing the tool paths.

- Well-trained operators: Skilled machine operators know how to select cutting tools, program machinery and carry out manual machining and lathing operations. They also know how to identify the quality of cutting tools and change the parameters if necessary. Just as importantly, a good operator knows how to protect the parts during and after machining.

- Programming software: High-end hardware won’t work to the best of its abilities if the g-code is sloppy and the tool paths are inefficient. We use HyperMill and SurfaceMill for programming.

- A strong quality control department: Good quality control won’t automatically improve tolerances, but it will make sure that parts outside the acceptable tolerance are not sent to a customer by mistake.

- Communication: Good communication with the customer and between staff leads to better results in the shop. It is important that the production department understands exactly what the customer needs — and communicates the actual possibilities back to the customer.

Conclusion

In conclusion, CNC machining plays a crucial role in meeting tight machining tolerances for various industries, from aerospace to medical devices. With the advancements in technology and the availability of high-precision equipment, manufacturers can produce parts with unparalleled accuracy and repeatability.

By leveraging the benefits of CNC machining, businesses can achieve cost savings, higher productivity, and superior quality products. With the increasing demand for tight tolerances, CNC machining will continue to be a valuable tool for manufacturers looking to stay competitive and meet the demands of their customers.

3ERP offers plastic and metal CNC machining parts. Learn more about our custom CNC machining services, and get in touch with our team for a free project review.