While injection molding is principally used to make plastic parts, the process is also highly effective for manufacturing large volumes of intricate metal components. Metal injection molding (MIM), a variant of the traditional injection molding process, has numerous advantages and can be carried out using standard plastic injection molding machines.

However, it is not always clear when injection molding is the best metal manufacturing process to employ, as the process has unique advantages and disadvantages when compared to other metalworking techniques like casting and machining.

This article explains when companies should use metal injection molding over other metalworking processes, i.e. when it is most economically and technically beneficial to do so.

What is metal injection molding?

Metal injection molding is a metal manufacturing process that closely resembles plastic injection molding. However, instead of plastic pellets, its feedstock is a mix of finely powdered metal and binder (such as wax or polypropylene), which is injected into a mold using standard injection molding machinery. Typically, the shot of feedstock weighs no more than 100 grams, limiting the process to smaller components.

After the injected material has cooled, the “green” parts must undergo further treatment. Heat or chemical treatment is applied to remove the binder material, resulting in a highly porous “brown” part comprising only metal. The brown parts are sintered at a temperature close to the metal’s melting point to increase their density and strength. Further post-processing steps such as plating or post-machining may be carried out afterwards.

Advantages and disadvantages of metal injection molding

Metal injection molding has its pros and cons, which ultimately determine the types of applications for which it is suitable and those for which it is not. The table below outlines the main points to consider.

Advantages | Disadvantages |

Allows for a very high level of part complexity and detail | High initial tooling costs make process unfeasible for prototyping or low-volume production |

Only requires standard injection molding equipment for base process | Unsuitable for large parts |

Enables fabrication of very small parts | Subject to general injection molding limitations such as thin and consistent walls (though draft is less important to due to the pliability of the binder material) |

Can produce very high volumes in short space of time compared to other metalworking processes | Requires more steps than plastic injection molding (debinding, sintering) |

Can produce features like holes, threads, surface textures, and markings without adding to individual cycle times (since these features are added to a single mold, rather than each individual molding) | Sintering can lead to shrinkage of around 15% which must be accounted for |

Compatible with post-processing steps like annealing and plating, as well as post-machining for very tight tolerances and additional complex features |

When to use metal injection molding

So why should you use metal injection molding? And when is it most effective? Based on its advantages and disadvantages, there are situations in which it is ideal to use metal injection molding and others where it is less useful.

In short, metal injection molding can be a highly valuable process in the following scenarios:

- When large quantities of parts are required (e.g. 10,000+) that would make alternative methods too slow

- When the part is small enough to fit in the palm of your hand

- When the part requires a high level of detail

- When the part requires a variety of features such as holes or engraved surface markings such as product codes or dates that would be impractical to add to each unit via machining

- When hard-to-machine metals (certain steels, for example) are required

Example applications of metal injection molding

Metal injection molding has been widely used across various industries since the 1990s, particularly for the mass production of micro-size components. Some components suited to the metal injection molding process are listed below.

Consumer goods

In the area of consumer goods like personal electronics, metal injection molding can be used for various small components such as watch cases, laptop hinges, heat sinks, buttons, vibrators, and loops for lanyards. Other uses include small metal parts for eyeglasses, toys, and various buttons and switches.

Medical

Metal injection molding has several important uses in healthcare, partly thanks to its compatibility with medical-grade metals such as titanium and stainless steels. For example, it can be used to fabricate large volumes of parts like surgical instruments, endoscopic and laparoscopic devices, dental crowns and implants, and custom fasteners for orthopedic implants.

Automotive and aerospace

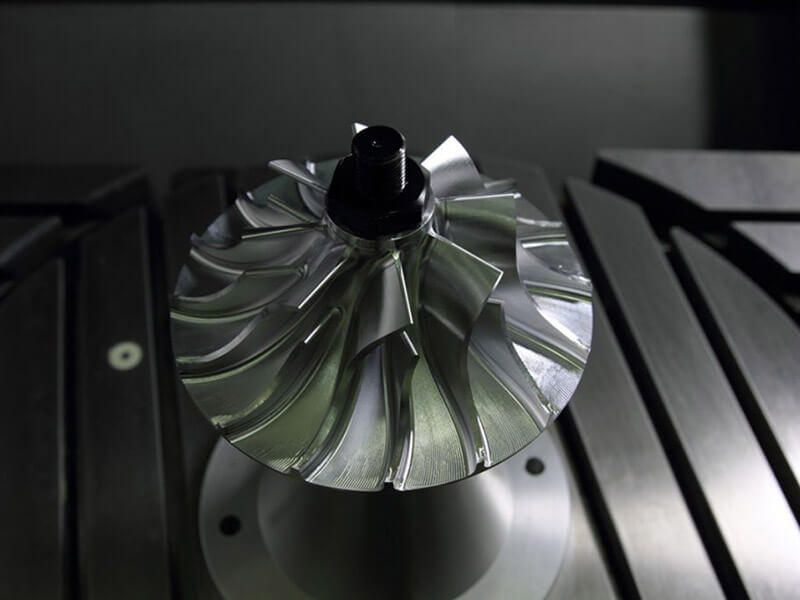

In the fields of automotive and aerospace, metal injection molding can be exploited for the production of small but valuable components. In car production, MIM can be used to make components such as sensors, transmissions synchronizers, and fuel injectors, whereas aerospace makes use of the process for parts like rivets and fasteners.

Defense

Due to their myriad intricate metal components, firearms are a key application area for metal injection molding, with the process regularly used to make components such as sight mounts, safety levers, and firing pins.

3ERP offers a reliable metal injection molding service for components made from alloy steel, carbon steel, stainless steel, iron, copper, nickel, or titanium. Contact us for a free quote.