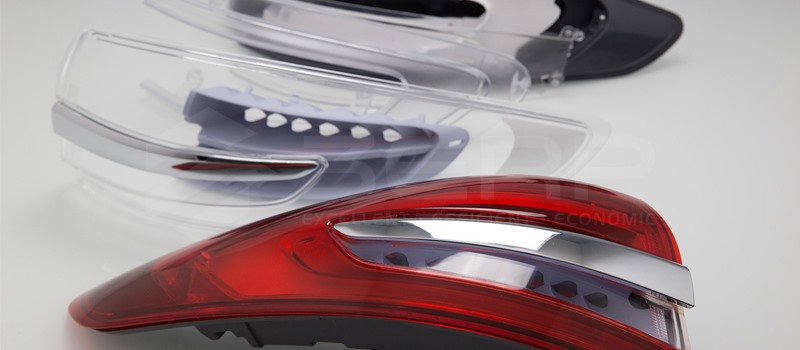

If you look at the tail light of your car, you might notice that, instead of making the whole lamp in red, it usually contains a clear, transparent area. That’s because red color is needed for brake indicator lights, while the transparent area gives enough light when your car is reversing. For mass production, it is really simple to get this done using 2k injection molding. But how can we achieve at the prototyping stage? Here are some solutions.

- Vacuum Casting. This process, also called silicone molding, is similar to injection molding. We can make either the transparent piece or the red piece first. insert it into the second silicone mould, and complete the whole part. But it is costly and risky. because we need two master patterns and two silicone moulds in order to get one molding.

- CNC Machining with Painting. This is a much simpler option. The whole lamp is made in one piece. Mask the transparent area and paint the remaining area in red. The only problem is, paint will create an extra layer on top of the part. When you peel off the masking material, you will surely break the edge, so it is almost impossible to get perfect lines.

- CNC Machining with Tinting. Our production engineers came up with this idea when we received a tail light RFQ from our customer. Since we had never done that before, we weren’t sure if it will would work out. So we did a test of this process on a flat piece, and it works quite well. And our customer is pretty happy with the result we got.

From the video you will see that we simply mask the part made of transparent material with tape (the packing material) to cover the area that must remain transparent, before submerging the part in red tint. The main difficulty is cutting the tape without scratching the part. You also need to make sure the tape sticks to the part properly without any leaks. So you will need a very skillful person to handle that task.

The tinting itself, though, is not simple. There are several steps during tinting, and each step needs to be taken carefully in order to get quality parts. We will provide more information about this in the future.