Prototyping is an essential element of the design and engineering process. Traditionally, though, it has created challenges as design teams strive to create makeshift models that provide a valid basis for a particular concept. This has, in the past, required nearly the same processes, costs, tooling and setup as the final product, making prototypes a prohibitive venture for many businesses. Rapid prototyping, in contrast, offers many advantages and applications that set it apart from traditional prototyping.

Defining Rapid Prototyping

Before diving into the numerous advantages and applications associated with rapid prototyping, it helps to define it. Rapid prototyping employs a diverse group of techniques that are utilized to quickly and efficiently fabricate a 3D scale model of a physical assembly or part. Because 3D printing, or additive manufacturing, doesn’t require any tooling and allows nearly unlimited freedom in form, it is a natural and complementary technique.

Rapid Prototyping Advantages

Rapid prototyping provides engineer, design and development teams with distinct advantage such as:

- The ability to explore and realize concepts more quickly. This efficiency in time and cost allows teams to move beyond the mere visualization of a product, making it easier to grasp the properties and design of a product.

- Apply repeated designs and incorporate changes that allow for the evaluation and testing of the product. This iterative process provides a roadmap to developing and refining the final product.

- Being able to communicate concepts concisely and effectively. Rapid prototyping takes ideas, images and concepts from flat and 2 dimensional visuals to hands-on products that clients, colleagues and collaborators can then see in action.

- The ability to thoroughly test and refine a concept. Being able to minimize design flaws with a small volume rapid prototype run helps eliminate costly design flaws that might not be evident during an early assessment.

- Save time and money since setup and tooling aren’t necessary. Because the same equipment can be used to produce prototypes with different properties and materials, the costs and time outlay are kept to a minimum.

Rapid Prototyping Applications

Rapid prototyping is applicable to many materials and technologies, making it a versatile technique that can be employed for numerous applications. A few ideas include the following:

- Concept models provide designers with the opportunity to validate both their ideas and the assumptions that lie behind them. A physical concept model is an ideal way to explore a concept, demonstrate its validity to stakeholders and/or create communication surrounding it.

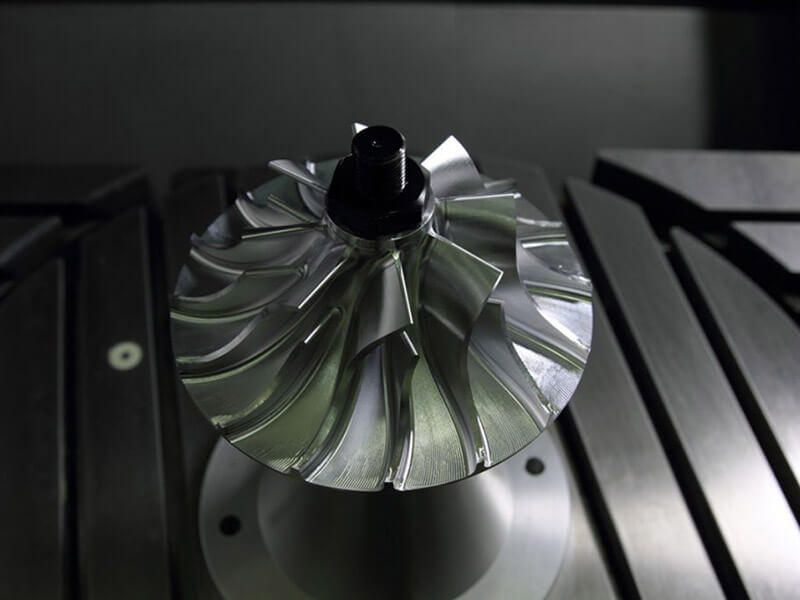

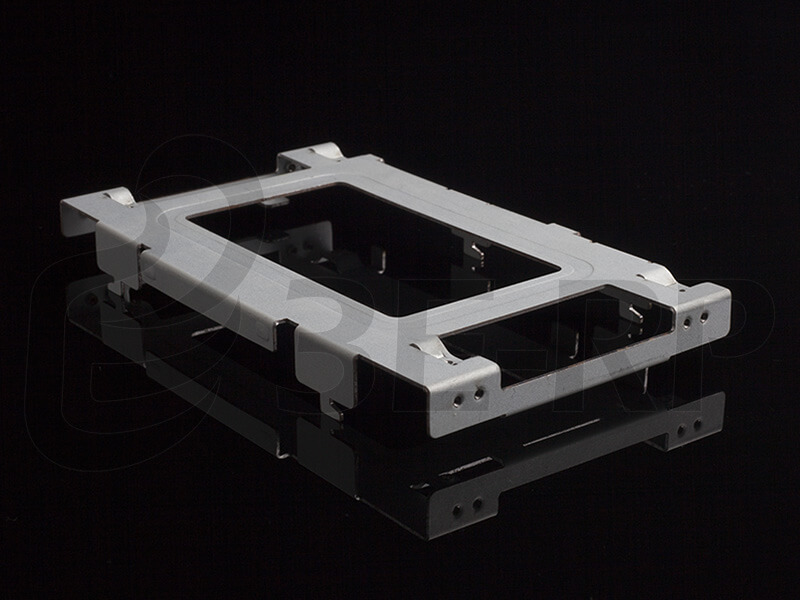

- Functional prototypes enable designers and developers to grasp the details that provide an accurate representation of the finished product by allowing them to verify its validity before it moves onto the next stage. The fit, design, manufacturability and function of the product can be tested prior to moving it into full production mode — an infinitely more costly process.

- Proving that a workable prototype is also going to be economically feasible to manufacture is another application of rapid prototyping. Having a fantastic prototype that achieves a satisfactory balance of functionality and aesthetics while also being cost-effective is possible with rapid prototyping.

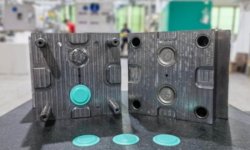

At 3ERP, we offer a range of rapid prototyping services to deliver the products you need quickly and efficiently — often in just 10 days or less. From 3D printing and sheet metal prototyping to surface finishing and pressure die casting, 3ERP is standing by to help you take your ideas from mere concepts to hands-on products. Contact us today with any questions or for assistance with your order.