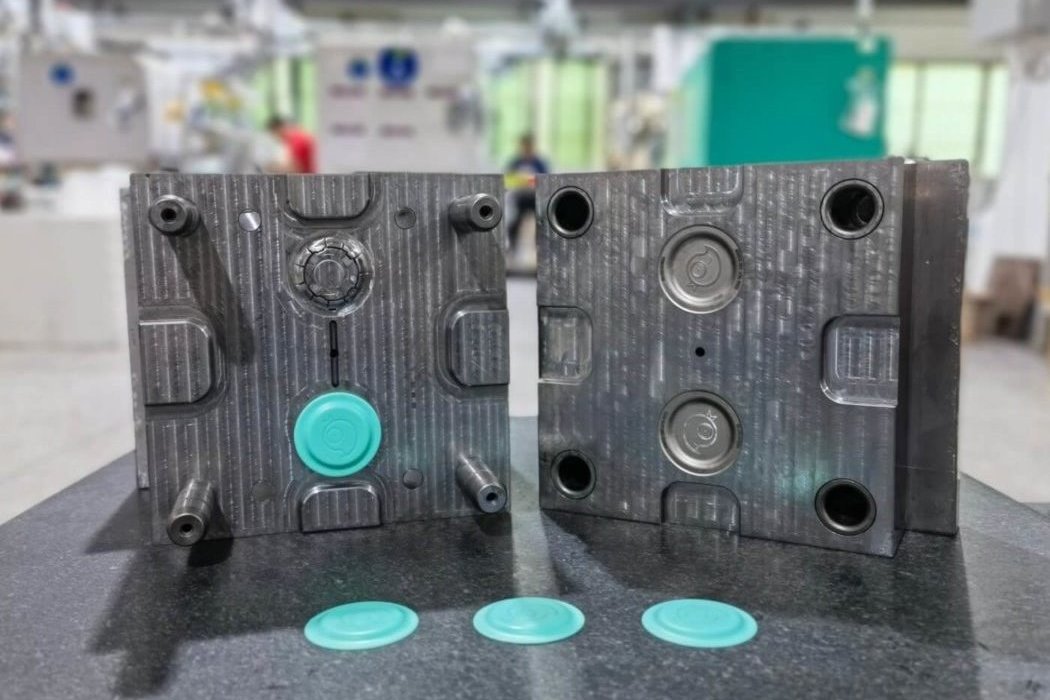

Rapid tooling enables engineers to get moldings much faster than they would with production molds. Via machining or additive manufacturing, rapid tooling massively reduces toolmaking lead times, making it possible to obtain accurate prototypes of molded parts or even low-volume production parts.

There are many key advantages to using rapid tooling systems. First and foremost, the speed (and lower cost) of rapid tooling makes it feasible to use molding processes like injection molding for prototypes, rather than settle for prototyping technologies like fused deposition modeling (FDM) 3D printing. This results in a prototype that is far more representative of the final part — one that can be made using the same technology and material — and therefore more useful for design validation and testing.

All in all, rapid tooling is a valuable process for engineers wanting to accelerate the development of molded parts. But how can this agile process be sped up even further? Here we look at five methods for speeding up the rapid tooling process for even faster prototypes and molded parts.

1. Perform DfM analysis before submitting the RfQ

When designing a mold for the fastest rapid tooling, engineers need to consider two stages of manufacturing. First, they must ensure that the tooling itself can be manufactured using the chosen moldmaking technology — typically CNC machining. Second, they must guarantee that the mold will be able to produce plastic moldings during the injection molding process.

Evaluating the design in these terms is known as design for manufacturing (DfM) analysis. At 3ERP, we carry out this analysis on all designs submitted in RfQs, ensuring that the design is feasible. However, product designers who want to speed up the rapid tooling process should perform their own DfM analysis before submitting their designs.

Most common CAD applications offer tools for DfM analysis, allowing designers to evaluate their designs for manufacturability while they are still being tweaked. For example, SOLIDWORKS offers the DFMXpress tool for assessing designs for milling, drilling, turning, and injection molding, which covers all the important bases for a rapid tooling design.

2. Scale down prototypes for large parts

At 3ERP, we fulfill more than 50 rapid tooling orders per month, getting through more than 10,000 prototype moldings. Of these tooling orders, the molds we can make the fastest tend to be simpler designs — ones that do not require slides or split cavities — that easily fit within a standard machining envelope. A standard part size of around 300 x 300 x 50 mm makes for faster tooling.

For large parts, designers might consider scaling down their prototypes to accommodate a standard CNC machine build envelope. While we operate several large-envelope CNC machines, large parts may have to wait in a longer queue to gain access to these machines, whereas standard-size parts can go straight to production on any machine.

3. Choose aluminum over steel for easier mold machining

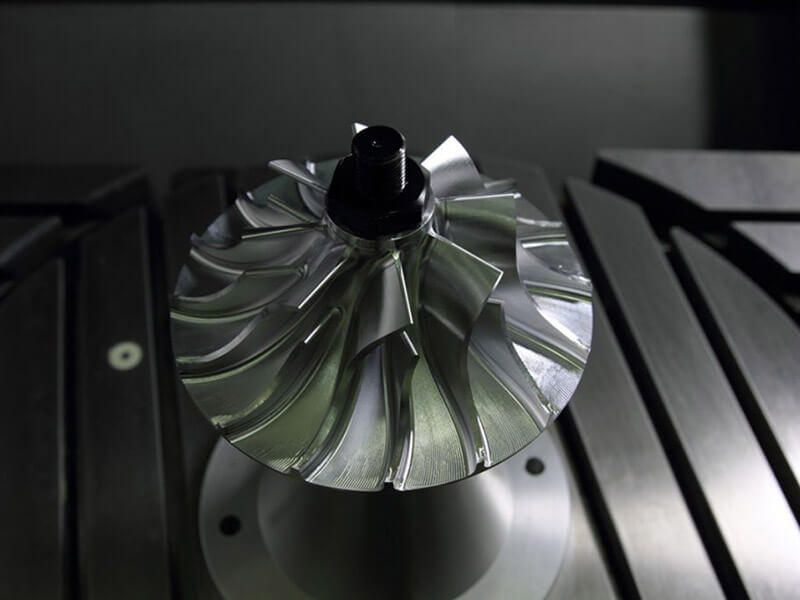

CNC machining is the standard process for making molds via rapid tooling, with the standard tool materials being aluminum or steel. This makes rapid tooling different to production tooling, in which hardened tool steel is used almost exclusively. While tool steel is more durable than aluminum and other types of steel, it is more expensive and takes more time and effort to machine.

Softer steels are a viable option for rapid tooling. However, aluminum molds are often the best choice for maximum speed — useful for quick iteration of prototypes, for instance. This is because aluminum is, despite its relatively high strength, extremely machinable: cutting tools can pass through aluminum quickly, allowing for high feeds and speeds.

Of course, aluminum molds can still perform to a very high standard, especially when a strong grade like Aluminum 7075 is used as the tooling material.

4. Minimize the need for extra setups and cutting tool changes

For the fastest rapid tooling orders, engineers need to make life as easy as possible for the machinist, cutting out any unnecessary features that could add time to the machining or molding operation. Overall, engineers can streamline the rapid tooling process by following standard machining design guidelines.

One specific way to ensure fast machining — especially on a 3-axis machine — is to avoid adding features that will necessitate extra setups. This is generally straightforward during toolmaking, as material is removed from one face of the core and cavity to realize the mold design. Another helpful procedure is to use consistent and standard hole sizes and radius sizes. This allows the machinist to use a single, standard cutting tool, preventing extra time being added to the operation.

Finally, when ordering rapid tooling from a machine shop, it helps to be cautious with tolerances. Specifying tight tolerances on features and dimensions adds significant time to the process, requiring extra machining time and inspection time; and while this may be important for the production parts, it is generally less of a necessity during prototyping.

5. 3D print molds for low-temperature molding

One experimental form of rapid tooling involves the direct 3D printing of tooling using a technology like stereolithography (SLA) with high-temperature resins. While we would only recommend 3D printed rapid tooling for low-importance prototypes and low-temperature molding plastics, fast progress is being made in the area of rapid tooling in additive manufacturing.

The principal advantage of 3D printed tooling is its speed. Although CNC machining is a fast process, 3D printing a relatively hands-off procedure that can print tooling within a matter of hours. Needless to say, plastic 3D printed tooling has a short lifespan, can handle only minimal clamping and injection forces, and is not suitable for production.

3ERP is a specialist in prototyping, machining, injection molding, and rapid tooling solutions. Our experienced machinists know how to produce all types of molds and can realize even complex designs in a short timeframe. Request a free quote for your next project.