After your team’s design has been validated with the development of a prototype, it’s time to look forward to the next phase. The plan for this next stage typically includes focusing on a solid course of action that is designed to bring the product to market in a way that positions it for success. Orchestrating a good plan enables your team to take full advantage of the resources that are available to it while successfully aligning it with your company’s capabilities and the demands of the current and future market. Here’s how to seamlessly move into this next phase of the design process.

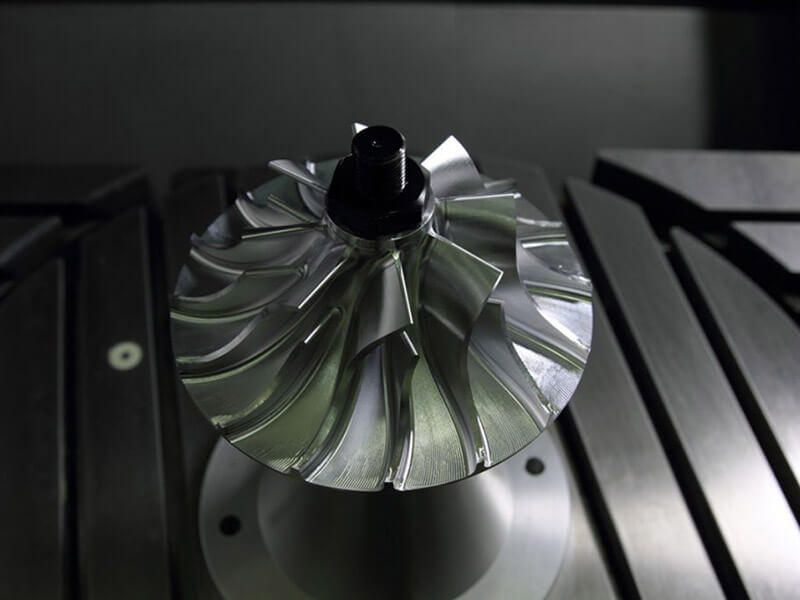

Manufacturing Methods

The method used in the manufacture of your component is a key to its success in the market. There is often a desire to use a particular manufacturing process that — unbeknownst to the engineering team — does not lend itself well to this application that is intended for the product.

There is no one-size-fits-all manufacturing method that works for every application and material. This is why is it so vital to consider the different elements that are at stake with every application. Indeed, there are often competing requirements that are at odds with one another that can add to the component’s complexity.

In spite of this, the top priorities of your design should serve as the impetus for its development. An experienced manufacturer is able to provide an objective assessment of the component, its purpose and other factors that are important in getting it to market. Tapping into the resources and experience that a manufacturer offers can effectively position your product in the market.

Market Demands

No matter how great a concept you and your team dream up, it’s likely that there simply won’t be a market for it. Perhaps the materials required for it make the cost for the target audience prohibitive. Maybe the manufacturing process requires such a long lead time that the industry can’t support it.

These elements highlight the reasons why it’s vital to work with an industry leader like 3ERP. With over a decade of experience in the rapidly-changing manufacturing industry, 3ERP has its pulse on the designs and trends that fuel developments. By partnering with us, you have access to their experience and expertise as you overcome obstacles and try to bring your concept successfully to market.

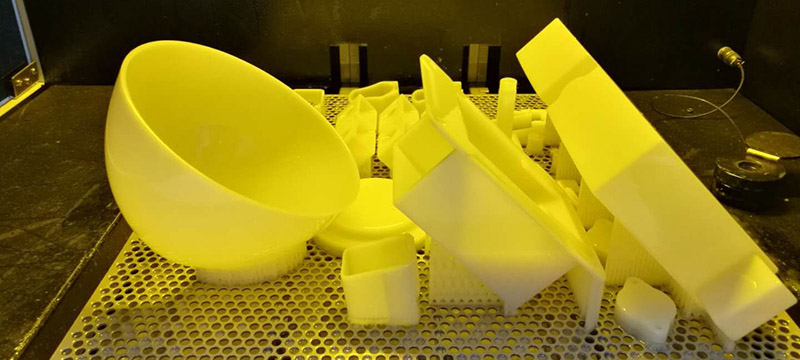

Materials

There are many considerations that must be kept in mind when it comes to choosing the right materials for your product. As engineers and designers, your team has to choose materials with the key characteristics that support its intended application. Some examples of these characteristics could include flame retardancy, production functionality, sterilization capability, end-product aesthetics, biocompatibility and more.

Working with a manufacturer who can quickly filter down through the possible materials to help you settle on a few possibilities saves you time, money and resources. As an added bonus, this manufacturer will already have experience working with the materials in question so the process can move seamlessly from design to production.

Feedback

It’s at this stage of concept development — after there’s a successful prototype in-hand and before it heads to market — that is ideal for gathering feedback from principals such as stakeholders and executives. A concept model provides a hands-on approach for displaying the product with its projected aesthetics and features during meetings. It allows key decision makers to see the concept in action.

These concept models are also an effective way to conduct market research. Because they can be manufactured in just a small-volume run, a concept model is a cost-effective way to test the reaction of a targeted audience before placing an order for a larger run.

Testing

Whether the ideal method of testing is to put the product through its paces via a machine or it’s best to gather a small testing audience — or even a combination of both — the phase after the prototype is the time to complete this step. Seeing your design in action by the applications and/or audience it’s intended for helps you determine if modifications need to be planned before it goes to market.

Being methodical in the development of your concept after the prototype lays the foundation for a successful introduction to the market. 3ERP offers a broad range of services that can help you with the engineering and manufacturing of your components. Request a quote today to get started!