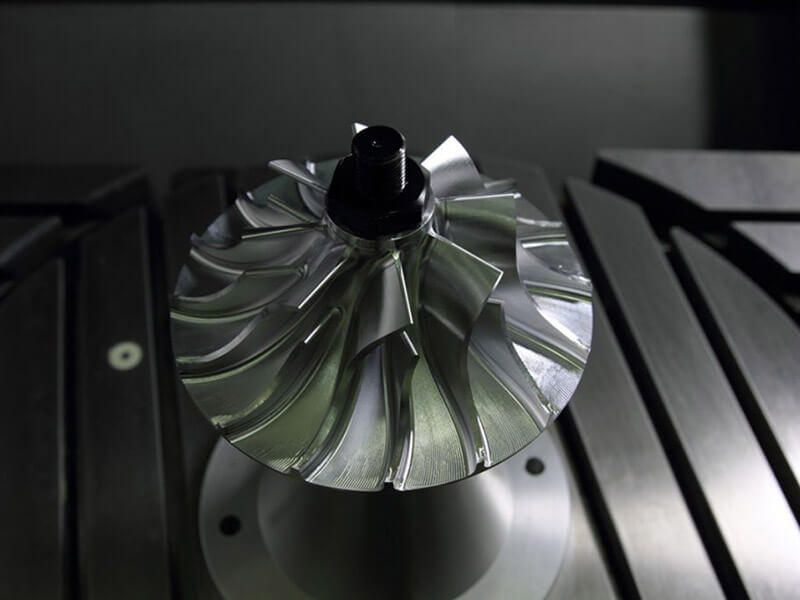

The manufacturing process of machining is a versatile and effective means of cutting metal and plastic. It can create very fine details with tight tolerances, and it is highly cost-effective for making prototypes and small batches of parts.

However, machining doesn’t work equally well for all materials. Because the process uses a powerful rotating cutting tool to remove sections of the material, the material must be soft enough to allow the cutting tool to penetrate it — otherwise the tool itself will become damaged and the quality of the part will suffer. Too soft, however, and the material will deform in undesirable ways upon contact with the cutting tool, leading to warped and ineffective parts.

The ease with which a metal can be cut with a cutting tool is known as machinability. But since there are many factors that determine a metal’s machinability, the characteristic is difficult to quantity. This article goes over the basics of machinability: what it is, which materials are most machinable, how machinability can be increased, and how machinability is measured.

What is machinability?

Machinability is a measure of the ease or difficulty with which a material can be cut with a cutting tool. A material that can be cut using minimal power, without causing deformation of the surrounding areas, is more machinable than one that requires more effort and causes more deformation.

In practice, using materials with good machinability provides short-term and long-term benefits. In the short term, using machinable materials can lead to better parts with tight tolerances, minimal deformation, and a good surface finish. They can also be made more quickly than parts made from hard-to-machine materials. In the long term, use of machinable materials leads to reduced tool wear and longer tool life, ultimately saving money for machine shops.

So why don’t machinists only ever use the most machinable materials? The problem is that machinability often comes at the expense of material performance, and vice versa. Strong materials are typically harder to cut than weak materials, so engineers often need to make a tradeoff between machinability and performance.

The machinability of a given material is dependent on both the scientific physical properties of the material group (what elements it consists of) and the condition of the specific work material (how it has been made). The physical properties of a material are fixed, but the condition of a workpiece can vary greatly.

Physical properties include:

- Work hardening

- Thermal expansion

- Thermal conductivity

- Modulus of elasticity

Condition factors include:

- Microstructure

- Grain size

- Heat treatment

- Hardness

- Tensile strength

Machinable materials

Aluminum

One of the most suitable materials for machining, aluminum is relatively inexpensive and manufactured in a number of common alloys. 6061 is the standard workhorse grade for machining, although less common alloys like aluminum 2011 and 8280 are even more machinable, producing very small chips and an excellent surface finish.

Steel

Steels are typically harder to machine than aluminum alloys, but grades with a moderate carbon content like 303 stainless steel are the most machinable (too much carbon makes the steel too hard; too little and it becomes gummy). Using lead as an additive can make steel more machinable, improving chip clearance. Sulfur can also increase the machinability of steel.

Other metals

Other machinable metals include various brass alloys, which are fairly soft but have good tensile strength. Similarly, copper has a good level of machinability along with characteristics like electrical conductivity.

Plastics

Thermoplastics can be difficult to machine, as the heat generated by the cutting tool can cause the plastic to melt and stick to the tool. With that in mind, some of the best machining plastics include ABS, nylon, acrylic, and Delrin.

Improving machinability of materials

Although metals have fixed physical properties, the condition of a workpiece can be altered to make it more machinable. Additives can also be introduced to alloys to improve machinability.

- Additives: One way to improve the machinability of a given material is to incorporate elements of other materials that will make it more amenable to cutting. When machining steel, for example, the addition of lead and sulphur can make the workpiece easier to cut.

- Heat treatment: Metals often undergo heating and cooling to alter their properties, and heat treatment can reduce the hardness of a metal to make it easier to machine. The annealing of nickel-based alloys, for instance, can lead to improved machinability.

- External factors: Machining can be made easier without actually changing the workpiece material. For example, adjusting the cutting tool material, cutting speed, cutting angle, operating conditions, and other parameters can make it easier to cut through a hard-to-machine material.

How machinability is measured

Because so many different factors affect the machinability of a material, machinability can be considered a vague concept that is hard to quantify.

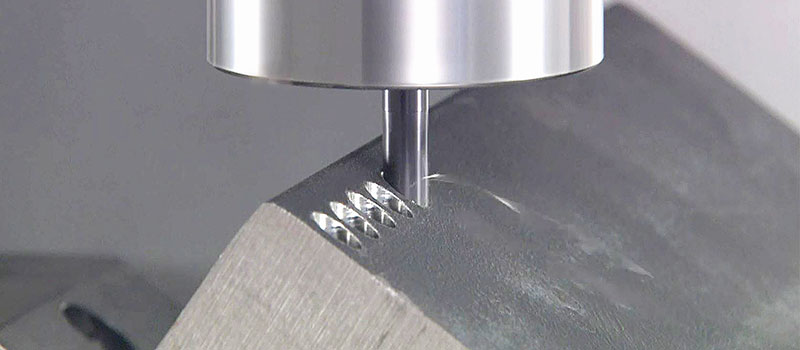

However, engineers and material scientists have attempted to measure machinability via metrics like power consumption (how much energy is required to cut the material), cutting tool life (how quickly the tool wears out when cutting the material), and surface finish (resulting smoothness of the cut material).

- Power consumption: Machinability can be assessed by the forces needed to cut through the material, measured using standard energy metrics.

- Cutting tool life: Machinability can be assessed by timing how long a tool lasts when it cuts through a given material.

- Surface finish: Machinability can be assessed by noting the degree of built-up edge produced during machining; highly machinable materials do not produce a build-up edge.

Unfortunately, none of these methods is fully reliable, as independent factors can affect power consumption, cutting tool wear, and surface finish.

The American Iron and Steel Institute (AISI) has also created a machinability rating system based on turning tests. These ratings, expressed as a percentage, are relative to the machinability of 160 Brinell B1112 steel (picked arbitrarily), which has a machinability rating of 100%. Metals with a higher level of machinability than B1112 have a rating above 100%, while those with worse machinability have a rating below 100%.

3ERP is a provider of CNC machining services and parts that can help you choose a machinable metal for your next project. Contact us for a free quote.