How accurate is 3D printing? The answer to that question depends on many factors, such as the type of 3D printing technology, the quality of the model of 3D printer, the 3D printing material, the complexity and practicality of the design, and the user-defined printing parameters.

Because 3D printers depend on a myriad of moving parts and materials, the process will never produce parts that are 100% accurate. (Nor will any manufacturing process.) However, additive manufacturing users can take steps to improve the accuracy of the printing process and ultimately make better 3D printed parts.

This article will look at the dimensional accuracy of 3D printed parts in general, how accuracy differs between technologies, and how users can make their parts more accurate.

What is dimensional accuracy?

Many people are curious about the dimensional accuracy of 3D printing, but the term “accuracy” often gets mixed up with other important concepts like resolution, precision, and tolerance.

In short, a dimensionally accurate part is one that matches the size and form of the original design. Accuracy is therefore the measure of a printed part’s closeness to the digital version, and this measure is usually expressed as a percentage or in millimeters, e.g. ± 1% or ± 0.5 mm.

The term accuracy is sometimes used interchangeably with tolerance, which is the allowable amount of deviation from the part’s true and intended dimensions. Note, however, that tolerance is also a user-defined value: a customer will specify an acceptable tolerance to a manufacturer depending on the importance of certain features and dimensions.

Accuracy is different from resolution, which refers to e.g. the pixel size of an SLA 3D printer. It is also different from precision, which concerns the reliability and repeatability of a 3D printer and its ability to consistently fabricate the same object.

The accuracy of different 3D printing technologies

Not all 3D printing technologies are equal in terms of how accurately they can print parts with their intended dimensions. Although other factors produce further variation, the type of additive manufacturing technology has a big impact on a part’s accuracy.

FDM

Fused deposition modeling in a polymer extrusion 3D printing technology that is moderately accurate and most commonly used for prototyping. In desktop form, it is by some distance the most affordable 3D printing technology, though it is also used in professional and even industrial contexts.

The accuracy of a desktop FDM 3D printer is around ± 0.5 mm. The accuracy of an industrial FDM printer is around ± 0.2 mm.

Resin

Photopolymerization printing technologies like SLA and DLP cure photosensitive resins using a light source such as a laser or a projector. These highly accurate technologies are used personally and professionally, with some machines costing not much more than FDM.

The accuracy of a desktop resin 3D printer is around ± 0.1 mm. The accuracy of a professional resin 3D printer is around ± 0.01 mm.

SLS

Selective laser sintering is a 3D printing technology that uses a laser to sinter particles of powder, typically nylon. SLS printers are accurate, although their main selling point is their ability to fabricate complex geometries, since they do not need to print support structures.

The accuracy of an SLS 3D printer is around ± 0.3 mm.

Powder bed fusion

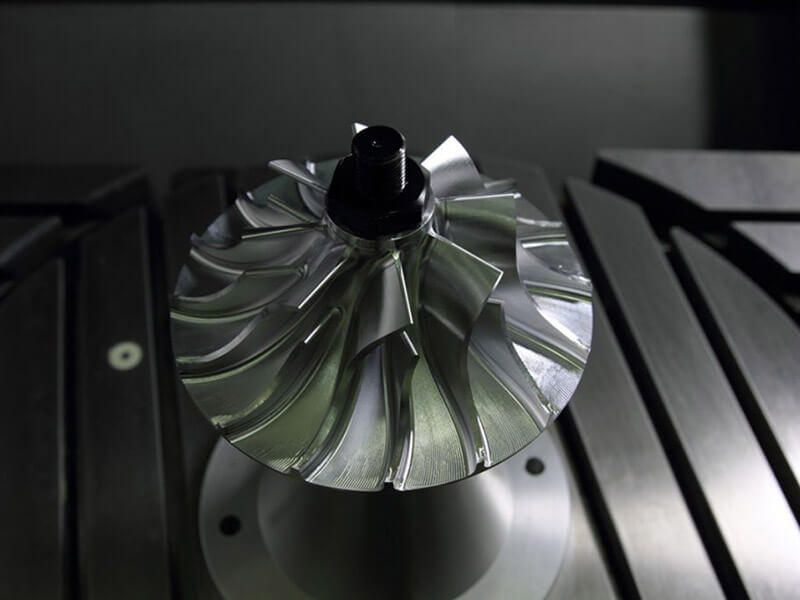

Metal powder fusion processes like SLM use a laser to melt or sinter metal powder particles. The technology is accurate, and there is no consumer-level version of it. However, metal additive manufacturing typically requires extensive post-processing.

The accuracy of a powder bed fusion 3D printer is around ± 0.1 mm.

Material jetting

Although less common than comparable technologies, the 3D printing process of material jetting is highly accurate since it does not require the application of heat, which causes deformation like warping.

The accuracy of a material jetting 3D printer is around ± 0.05 mm.

Other factors that affect dimensional accuracy

The type of 3D printing technology is not the only factor that determines the dimensional accuracy of a 3D print. Materials, part design, and printing parameters also have a big impact on how closely the printed part matches up to the original design.

- Printer quality: There is a large gulf in quality between high-end machines and entry-level ones. For example, SLA 3D printers are typically more accurate than FDM printers, but a very low-cost SLA machine will produce less accurate parts than a high-end FDM printer.

- Part design: Even the very best 3D printers will struggle to accurately 3D print a part that has been designed poorly. Parts with long and thin features — especially features without adequate support — are difficult to print, while very large parts can also bring about issues. In general, designs should not contain features smaller than the printer can handle.

- Materials: Some materials are easier to print than others and are therefore more conducive to the fabrication of accurate parts. Nonstandard materials (like flexible FDM filament, high-temp filament, or alloys containing precious metals) tend to sacrifice printability in favor of their own unique advantages.

- Printing parameters: Besides calibration — which is essential for making accurate prints — users can tinker with their 3D printer setting to achieve various outcomes. Some configurations of parameters are better at printing fast, while others are better at printing accurately. See next section for more information.

How to improve 3D printing accuracy

Although you can’t tweak a cheap 3D printer into making industrial-quality parts, users can achieve better 3D printer accuracy by changing certain printing parameters and taking other important steps.

- Design parts with the printer in mind; remove or simplify difficult features.

- Export STL files in the highest possible resolution.

- Calibrate the 3D printer at regular intervals or before important print jobs.

- Use supports to stabilize objects as they are being printed, and be careful when removing supports so as not to cause damage to the part or alter its final dimensions.

- Use a heated print bed (FDM) or heated chamber (SLS/metal) to keep a consistent temperature across the part and reduce deformation.

- Adjust the tension of the printer belts, ensuring that they are tight but not overly so. The drive gears should not slip.

- Straighten linear rods and rails, as well as lubricating them where needed. Bent rods and rails should be replaced immediately.

- Decrease printing speeds by adjusting settings like flow rate. Although too much of a reduction can cause other problems, slow printing can help reduce inaccuracies.

How warping and shrinkage affects accuracy

Most 3D printing technologies produce small amounts of deformation during printing, most commonly warping and shrinkage. Parts that show signs of warping and shrinkage will be less accurate than those that don’t, since the deformations ultimately change the final shape and dimensions of the part.

In most cases, the extent of the deformation is negligible. For critical parts, however, it is important to try and mitigate these unwanted effects.

Methods to counter warping and shrinkage include using advanced print simulation software, using heated print beds and printing rafts (FDM), using materials with a lower melting point (FDM), using stiffer materials (resin), leaving finished parts in the printer for a set time (SLS), or simply using a technology like material jetting where deformation is unlikely to occur.

3ERP is a trusted provider of 3D printing services. Request a free quote for your next 3D printing project.