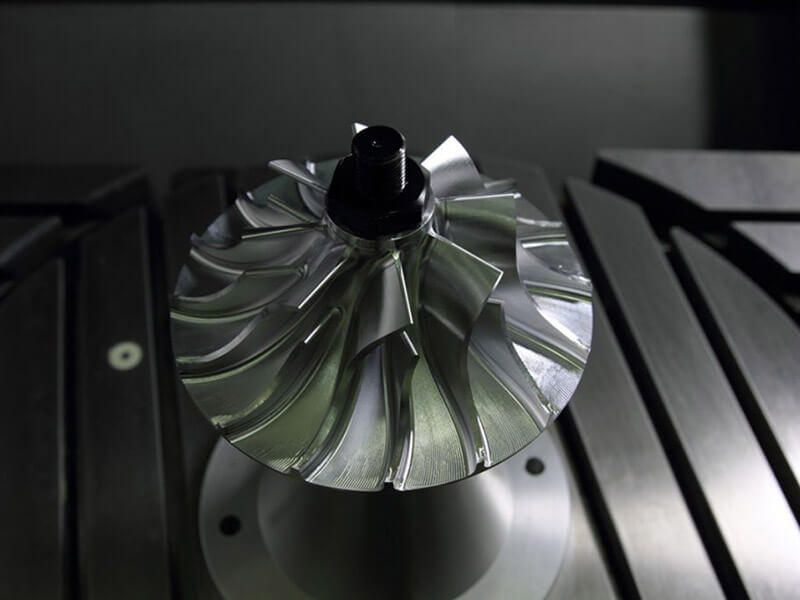

If there’s a technological device that truly defines our current generation of science and technology, it must be the smartphone. These ever-evolving bars of glass, plastics and electronics have taken on a massive portfolio of functions, offering operations just as diverse as computers (if not more) while providing far more ease of use and portability in daily life. Their popularity has also meant that manufacturing has had to step up its game. This is not only in the direct production of smartphones but also all of its peripherals and accessories. Naturally CNC machining has a lot to offer in the electronics industry.

Bringing in just the right amount of speed and volume of production, various types of lathes and mills are proving to be a key part in a lot of smartphone manufacturing activities. The level of precision is unparalleled and leads to some very novel design choices. Here are just a few of the ways CNC is contributing to those marvelous pocket computers we all rely on.

Frames & Bodies

Let’s start with the most noticeable component of the entire smartphone: the physical exterior that props up the entire thing and keeps it secure. These exteriors, such as those on the average iPhone, can be made with aluminum.

This makes CNC machining a particularly potent choice of manufacturing method. The technology is especially convenient for shaping the sleek, rounded edges of Apple’s designs, which have become a hallmark of the company’s in-house style. Getting those corners to be accurately produced in a repeatable and reliable manner requires precise CNC milling and laser cutting.

Apple

Apple, in particular, are fond enough of CNC milling that they bought 10,000 of them to make their Macbook Pros and use them extensively for the iPhone manufacturing process, as well.

At the peak of its production rate, Apple manufactured roughly 1 million iPhones per day. Each of those phones is sculpted to 10-micron tolerances using a single block of aluminum. The same is true of every Mac, iPad, Watch and many of their accessories. Swiss style lathe machines are particularly popular among their manufacturing facilities, with numbers of lathes reaching up to the tens of thousands. These machines produce all sorts of parts, but are most prominently used for those exterior features.

Samsung and Huawei

Similarly, Samsung and Huawei have also been prominent in their application of CNC machining for the exteriors of their phones. The wider smartphone industry has found that these aluminum and alloy parts are more durable than their plastic predecessors. Companies tend to use this as a selling point, boasting about the improved qualities of alloy and metallic frames for their phones.

However, while larger manufacturers can manage the scale that is required to process these aluminum frames and bodies, but smaller, cost-effective manufacturing companies tend to go for plastic cases. These are particularly prominent among lesser known brands among cellphone companies, and are often injection-molded. Even among the production chains for such phones, CNC machining is often employed in developing the molds or smaller metal components like the rigid metal elements within the frames.

Smaller companies, particularly those in China, also receive sub-contracts to produce frames and metal upholsteries for repair. Occasionally, if they are big enough to manage the workload, they can also provide parts to manufacturers. These companies can easily be found all over the Internet and can quickly manufacture parts for various clients.

Cases

Another exterior feature that CNC machining can add some very novel features to is the phone’s casing. The most common casings are leather and plastic, so most cases and protective covers are not generally made with CNC machining, relying instead on injection molding or sowing operations depending on the material and scale of manufacturing. However, CNC machines can often play a major role in the production of the molds that are used in the injection molding process.

Even aside from those previous applications, CNC machines do have a definite advantage when it comes to both metal and wooden cases. Metal cases can be great, as they offer quality protection, a unique look and prevent the device from overheating. CNC machining can cut and mill the exact shape of the phone into the case, getting around those difficult edges with precision.

While wooden cases are usually quite expensive, often consisting of bamboo, teak or elm, they can be also be stylish. Some are crafted by hand, but CNC machined cases make up most of the production, being cheaper and easier to produce. The main draw for applying a CNC machine for such tasks is that manufacturers are able to mass produce wooden cases quickly and accurately.

Companies like Kerf operate full-fledged production operations utilizing CNC machines for these unique and reliable types of wooden cases, catering to all sorts of phones. The company also has partnerships with Urban Tree, which rescues felled trees in the Pittsburgh area. As a bonus, this makes their project much more sustainable. The company claims that their exotic hardwood collection is not sourced from countries that exploit their natural resources or deal in endangered species.

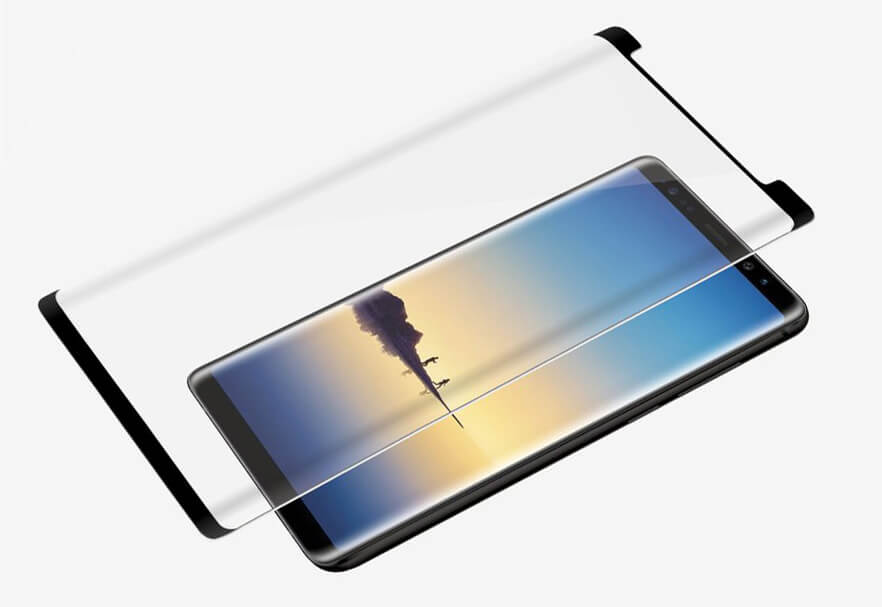

Touch-sensing Glass

Touch sensing interfaces are a major part of modern technology as a whole, but are entirely vital to the smartphone. They are also used in various commercial products such as smart watches, mobile phones, tablets and TVs. CNC machining has contributed to this complex product in a number of ways, but glass milling is probably the most significant one. It allows manufacturers to produce varieties of shapes and even slots on the glass surface.

The main draw of using CNC milling machines to make such glass interfaces is their propensity for batch production, along with the ability to meet the high quality per unit necessary for such a task. Other types of machines can’t always manage to produce glass with the surface quality required, thus grinding processes on a CNC milling machine provide an ideal solution in manufacturing complicated special products.

Cutting and CNC grinding are also used to develop gorilla glass and protective screens. In conjunction with chemical toughening measures, the glass can provide high scratch and crack resistance. It also brings in a fair bit of transparency and high optical quality for a better-looking screen overall. Aside from smart phones, this type of glass is always used for computer monitors, TV screens and plain old interior design.

Aesthetic Flourishes

The look of a phone can be a compelling thing. This is why companies are paying more and more attention to the little aesthetic touches that make their product stand out. The Xiaomi mi 8 uses a mural-esque depiction of the inside of the interior which is depicted on the back of the phone. This little touch was done with a CNC engraving machine, etching that image onto a 0.3mm aluminum sheet using a with a tiny cutter.

This same principle can extend to plastic covers that can put some extra flourish to a user’s phone. Plastic covers with embedded designs can be swapped out in case you get tired of an old one. These can even be made from recycled plastic, allowing for a more sustainable mode of production that allows the end-user to customize it to their own tastes.

Peripheral devices and Accessories

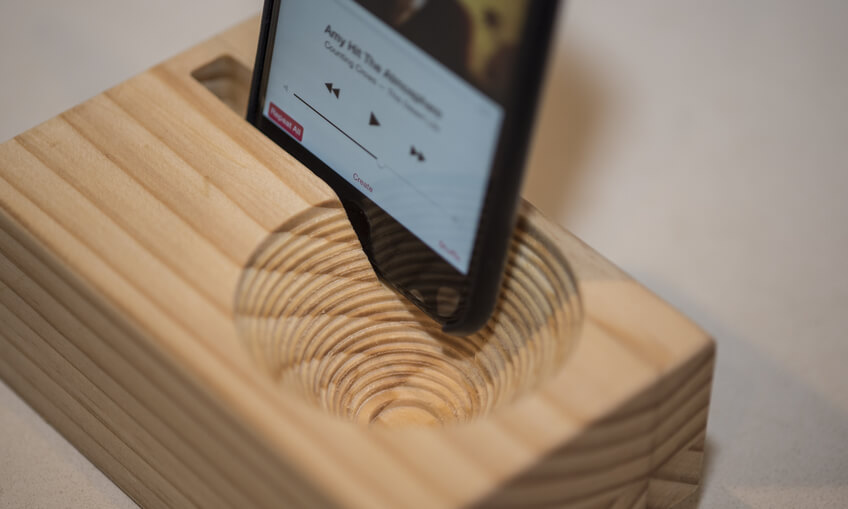

Figure 3 X Carve Phone Amplifier

Phone applications don’t just end with the phone itself. There are so many add-ons one can buy to spice up their smartphone usage, and CNC is making such peripheral devices even easier to produce.

One example is the selfie-stick. Custom CNC milling services and parts allow for companies to quickly produce all the little nuts and bolt that go into the selfie stick. This can be something as easily misplace-able or breakable as a screw. In fact, many companies can provide manufacturers with machined parts that are significant improvements (titanium variants for extra strength). This can help you make your own part in your machine shop or repair an old one. Another example is improved housings for an external power source or power bank. Need to protect these sorts of energy sources? Give it a protective casing with a better, more rigid material.

There are other more ingenious yet unconventional options on the market. X Carve’s work with a simple, non-electronic, wooden phone amplifier is a marvel of CNC machining. The simple design simply takes a wooden block and cuts a series of shrinking circles into it with a slot to place you phone along its arc. This allows that small acoustic hole to amplify the sound. The beauty of the design is that it’s easy to make and available online for machinists everywhere to try.