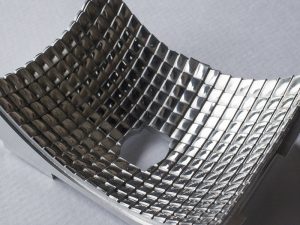

Typical CNC Machined Zinc Parts We Offer

We machine custom parts in zinc for clients requiring rapid prototyping and for low-volume to mass production orders. Our CNC-machined zinc parts include bearings, gears, valve bodies, fittings, couplings, decorative pieces, and many more.