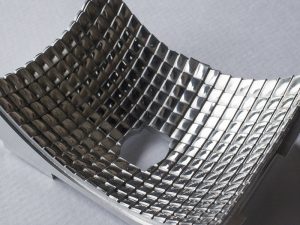

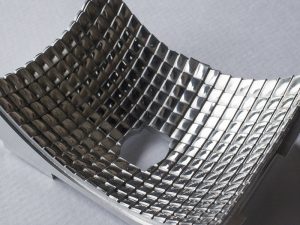

Typical CNC Machining Parts That We Offer

We machine custom parts for customers in multiple plastic and metal materials, from rapid prototypes, low-volume production to mass production orders.

For industries ranging from medical to power generation, stainless steel is a ubiquitous metal thanks to its strength and heat resistance. But what sets different types of stainless steels apart is their superior corrosion resistance.

Trust 3ERP – the expert in delivering precision results for a wide range of stainless steel alloys available for CNC machining.

| Applications | CNC machining produces parts with excellent mechanical properties, accuracy and repeatability from metal and plastic. 3- axis & 5-axis CNC milling available. |

| Strengths | Excellent mechanical properties,High accuracy & repeatability |

| Weaknesses | Greater geometry restrictions than 3D printing |

| Lead Time | < 10 days |

| Wall Thickness | 0.75 mm |

| Tolerances | ±0.125mm (±0.005″) |

An age-hardened stainless steel alloy with excellent tensile strength, wear resistance, and high hardness, frequently used in aerospace components, medical instruments, and valves, as well as hand tools and fasteners.

Tensile Strength, Yield: 1275 MPa

Shear Modulus: 75 GPa

Elongation at Break: 9.8 %

Hardness (Brinell): 420

Density: 0.282 lbs/in³ (7.8 g/cm³)

Maximum Temp: 1508°F /820°C

The Top 6 Reasons:

One-off aluminum prototype part or large quantity parts. No matter the size of your order, we can handle it.

We have 40 machines at our disposal and can take your project from engineering design to delivery faster than our competitors.

We have 40 machines at our disposal and can take your project from engineering design to delivery faster than our competitors.

Our team has years of experience in a wide range of industries and can handle even the most challenging projects.

We service the aerospace and medical industries and can produce parts with tight tolerances. We also use precise tool holders and tools to ensure optimal precision and accuracy.

We can offer a wide range of coatings and finishes for your parts depending on your project requirements.

As-Machined: As-machined is the most basic and economical CNC finish, often used in applications where the surface won’t be visible, and appearance isn’t a priority.

Bead-Blasted: Bead-blasted CNC machining produces a matte finish with texture and evenness. The finish is achieved by blasting stainless steel with an abrasive media such as glass beads, aluminum oxide, or silicon carbide. Bead blasting creates a consistent look in end products with multiple parts machined from the same material.

Anodized: Anodizing creates a protective oxidation layer on the surface of a part, usually through electrochemical processes. Anodized CNC machined parts can be dyed in different colors. This finish is often used for stainless steel parts that will be exposed to an outdoor environment, as the oxidation layer helps protect them from rust and corrosion.

Powder-Coated: Powder coating is a type of finishing applied to machined parts, where a polymer-based powder coating is melted and cured onto the surface. It’s a durable and cost-effective finish that can be used to add color and texture, as well as provide additional corrosion protection.

CNC machining has for several years been an integral part of aerospace manufacturing. That’s partly down to the extremely high precision of CNC machines, making the process suitable for safety-critical parts that will be used on aircraft.

Machinable aerospace parts include prototype engine components, fuel panels, landing gear components and engine mounts.

CNC machining and EDM are the main methods to fabricate metal tooling for injection molding, high pressure die casting, blow molding, roller molding, stamping, blending and so on.

High speed CNC machines allow us to make high precision copper patterns, mold cavities, mold base, lifter and other mold components in very short term. Moreover, with 5 axis milling machines, we can mill the deep pocket features in hours which take days to make by EDM in the past. That’s how we can speed up the mold making process significantly. Check out how rapid tooling works.

in 4 Simple Steps

To start, simply fill in a few information and upload a 3D CAD file.

You'll receive an online quote shortly, and we'll send you design for manufacturability (DFM) analysis if necessary

Once you review the quote and place your order, we'll start the CNC manufacturing process, and surface finishing afterward as well if needed

Your CNC prototypes or production CNC machining parts will be inspected and delivered straight to your doorstep

We machine custom parts for customers in multiple plastic and metal materials, from rapid prototypes, low-volume production to mass production orders.