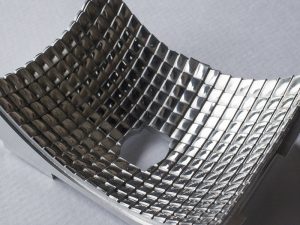

CNC-machined copper parts are used in a wide range of industries and applications. From aerospace, automotive, and medical devices to household items such as furniture, 3ERP can create precise parts with a high level of accuracy.

Example parts:

AEROSPACE: Airframes, Engines, Landing Gear components, and Electrical Applications.

AUTOMOTIVE: Fuel Lines, Spark Plugs, and Pump components.

MEDICAL: Surgical Instruments, Drug Delivery Systems, and Prosthetics.

HOUSEHOLD: Furniture, Fixtures, and Decorative Items.

INDUSTRIAL: Fasteners, Fittings, Connectors, Bushings, Gears, Actuators, and Heat Exchangers.

Overall, 3ERP’s expertise in copper part manufacturing can help create parts that are reliable and cost-effective without sacrificing quality.

Whether it’s for aesthetic, functional, or industrial purposes, 3ERP offers the highest quality CNC machined copper parts.

Medical equipment and devices must be extremely precise and accurate to ensure patient safety. 3ERP can produce precision-engineered titanium components using CNC machining. Our services are used in various medical devices such as orthopedic titanium implants, dental products, and surgical tools.