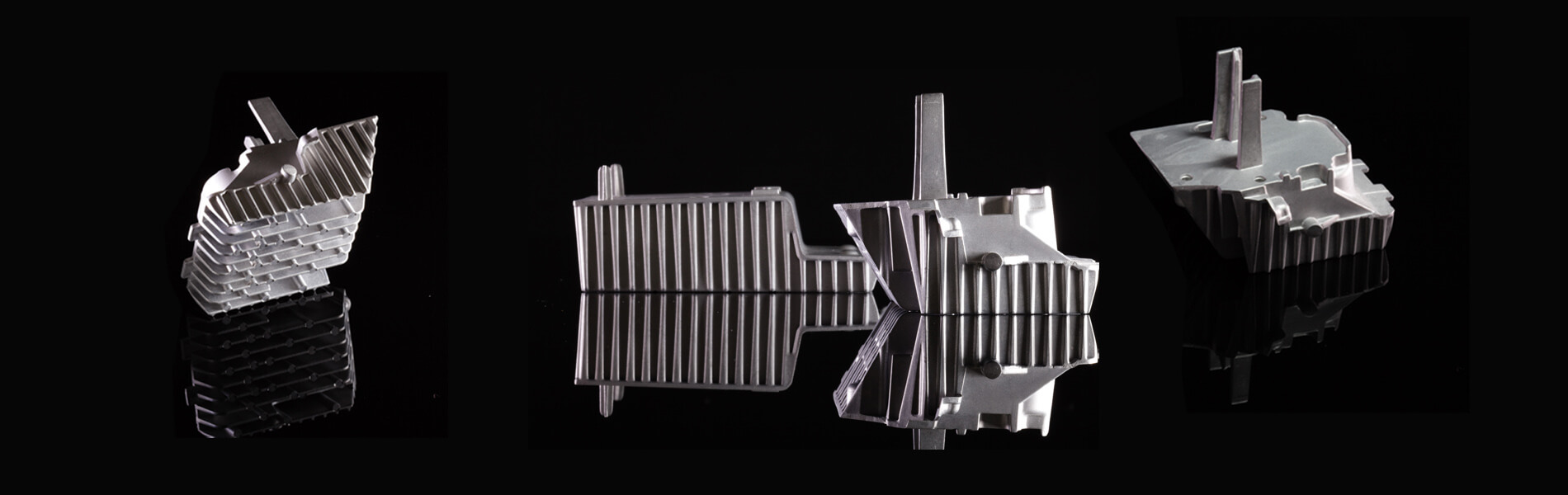

Aluminum, Magnesium, Zinc & Steel

One-off prototyping or 1000+ production parts

While delivering prototypes to customers, we were frequently asked if we could provide low-volume metal casting services. Because of this, we started to look for metal casting suppliers in order to fulfill those needs. Unfortunately, the search proved frustrating. Big casting companies showed no interest in low-volume production, while the small casting companies couldn’t meet our quality requirements. It presented a challenge, but we took it as a business opportunity: if it was difficult for us to find the right companies for these projects, we knew it would be a good deal harder for overseas customers to find them.

After two years, we successfully developed relationships with a handful of medium-size casting partners who can meet our quality requirements and lead time requests. We are now able to offer high-pressure die casting in aluminum, magnesium and zinc, as well as investment casting in brass and all types of steel.

It might sound counterintuitive to use a RP company for metal casting services, but we offer very good reasons for doing so:

A process similar to injection molding, pressure die casting is a metal casting process in which molten metal is forced into a mold cavity to create metal parts. At 3ERP, we use certified machines and pressure casting dies to form your designs from molten metal — typically zinc, copper, aluminum, magnesium, lead, pewter or other tin-based alloys. Our pressure die casting process is effective and very reliable, and can result in significant cost savings. Because of our flexibility, we can accommodate any project needs you may have – from small batches of 50 to as many as 1,000 pieces.

Metal casting can be used to make very large parts with high tensile strength and complex parts with undercuts. Sometimes there is no alternative.

We have a group of reliable casting partners who fulfill our casting needs, and we use low-cost 3D printed wax patterns to reduce the price for the customer.

We are adept at CNC machining extra features (such as engraving and minor details) onto cast parts.

We generally accept metal casting orders of no fewer than 10 units.