At 3ERP, our reliable rapid prototyping services have served many customers representing different phases of the aerospace industry over a decade. We can quickly create aerospace part prototypes and our production systems can produce parts in small, batch, or large-scale quantities with high quality standards and affordable price.

ISO certified

3E Rapid Prototyping (3ERP) is an ISO9001-2015 certified manufacturer that can guarantee top quality parts in an industry that demands rigorous consistency and quality control.

Huge production capacity

We can fulfill orders of virtually any size, from one-off engine part prototypes to full production of injection molded headlamp covers.

Range of services

Equal parts machine shop and digital manufacturing specialist, we offer a range of manufacturing technologies and services, from CNC machining to 3D printing.

Short lead time

Our extensive facilities and partner network allow us to fulfill orders quickly, no matter the quantity or complexity.

Skilled and experienced

We have been manufacturing aerospace parts for over a decade and our skilled engineers know how to get the best outcomes from your designs.

Easy quotation system

Our engineers will review your designs immediately to provide a fast and accurate quotation for the project.

Aerospace prototyping and manufacturing with 3ERP

What kind of aerospace & defense parts can we make?

- Seats

- Engines

- Fuselages

- Turbines

- Fastening Items such as Screws

- Tire Parts

- Brakes

- Electrical Parts

- Radar Systems

- Air Conditioning Systems

- Vacuum Pumps

- Fuel Pumps

- Lighting System

- Gears

- Wing Support

- Night Vision Device

- Transmission Components

- Dashboard

- Helmets

- Unmanned Aerial Vehicle

- Teaching Aids

- Tank Model

- Protective Gear

Aerospace manufacturing

processes

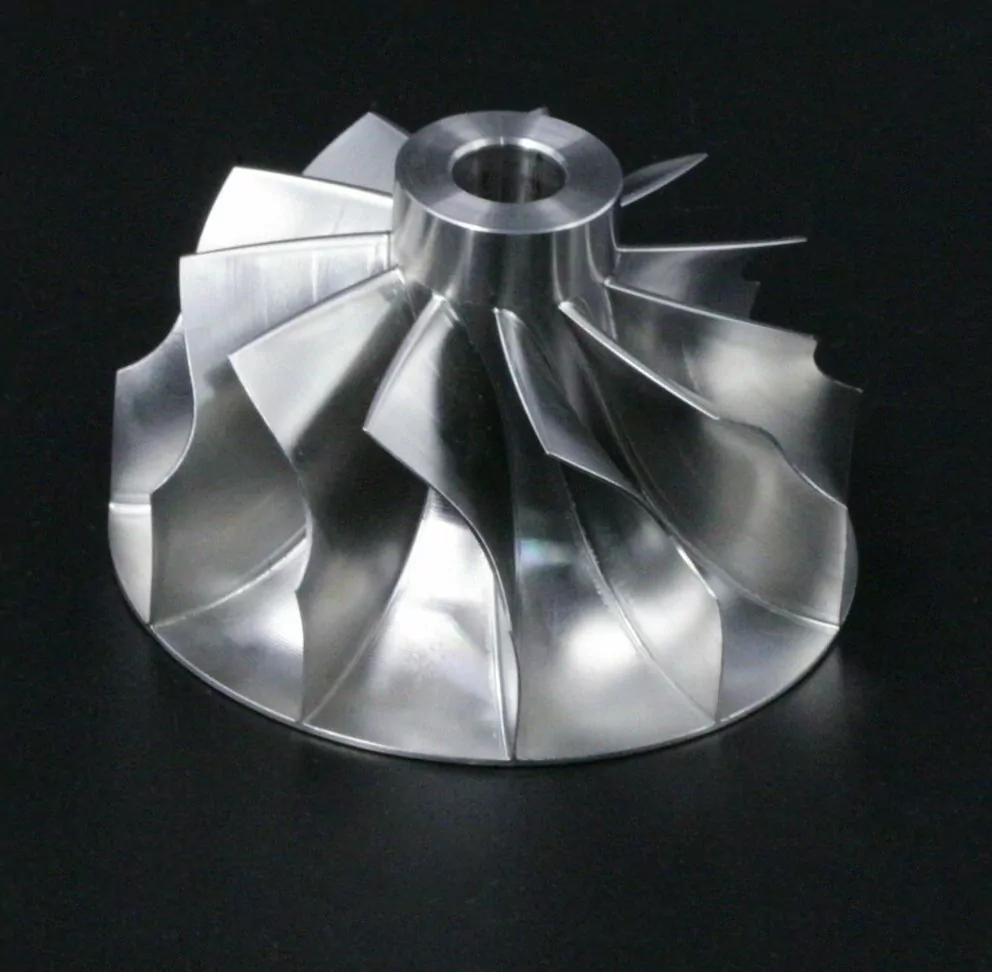

CNC Machining

By using CNC milling & turning, we can make a wide range of prototypes and production parts

Injection Molding

We offer low-volume prototype moldings and mass production moldings.

3D Printing

We provide 3D printing services using a range of cutting-edge additive manufacturing technologies for metal or plastic parts

Sheet Metal Fabrication

Laser cutting, bending, stamping, spinning, punching, welding.

Aerospace Part

Gallery

Aerospace manufacturing materials

We offer a huge range of material possibilities with all our manufacturing processes. Some common choices for aerospace projects are listed below.

Applicable Finishes For Aerospace Industry

3ERP offers wide variety high level surface finishes. We only list some of the common finishing options. There are more finish options for custom parts for Aerospace Industry.

Aerospace Faqs

into production today