Whatever your sport — be it running, football, tennis, cycling, swimming or something else — proper equipment can always help improve performance. Even in a relatively basic sport like running, possessing equipment like a technologically optimized pair of shoes and a breathable outfit can be the difference between winning and losing.

On the other end of the spectrum, a sport like road cycling demands even more from its equipment: gears, wheels and frames need to be perfectly crafted to ensure high performance; a skilled cyclist can only take a mediocre bike so far.

Now more than ever, advanced manufacturing technology is being embraced across all sports because athletes know that expertly crafted equipment can help them achieve their goals. But while most sports equipment brands use mass manufacturing processes to produce their bats, rackets, sneakers, clubs, helmets and everything in between, there is a growing place in the sports world for on-demand manufacturing.

Whether it’s for a prototype that will later be developed into a marketable product, or for a customized one-off device that will be used at a professional level of competition, on-demand manufacturing processes — CNC machining, additive manufacturing and the like — give companies the chance to quickly iterate sporting equipment in small quantities.

This article will look at three of the ways that on-demand manufacturing is being used to create the next generation of game-changing sports equipment.

CNC machining custom golf clubs

Professional golfers possess great skill and composure, but those golfers also require elite golf clubs to play at the highest level. And for some players, the demand for the best clubs necessitates the need for on-demand manufacturing. Why? Because it allows for a high degree of customization on the club, which can be tailor-made to suit its user.

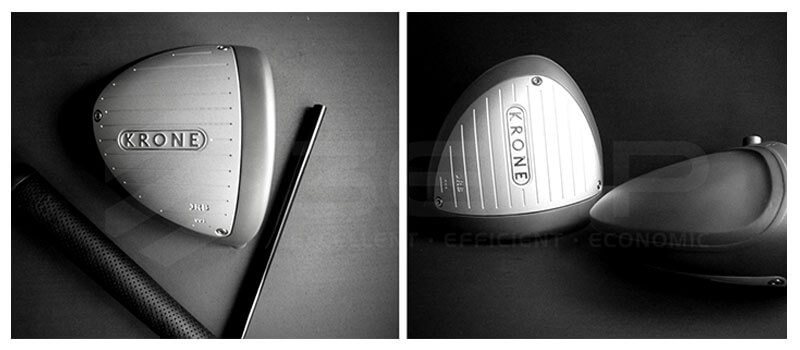

For a few years now, golf equipment company Krone Golf has been using on-demand manufacturing techniques like CNC machining and 3D printing to create customized clubs. Last year, the company unveiled its new KD-1 driver, complete with a 3D printed body made using SLS 3D printing technology and a CNC machined titanium strike face.

According to Krone, combining CNC with additive manufacturing both reduces touch labor and results in parts with tighter tolerances. And although store-bought clubs remain par for the course for most players, the amazing developments by companies like Krone show that on-demand manufacturing could totally change the way golf equipment is made.

3D printing safer helmets

On-demand manufacturing processes aren’t just making athletes perform better; they’re also keeping them safe — with the creation of partially 3D printed helmets, for example.

3D printing isn’t suitable for everything, but its ability to create lightweight, partially hollow “honeycomb” structures means engineers can create incredible strong, incredibly light 3D printed structures. A few years back, this area of 3D printing caught the attention of researchers at Cardiff University in the UK, who developed a multilayered elastic material for American football helmets.

Followers of the sport will know that American football has been mired in controversy in recent years. Besides its current political problems, the sport has also been having big discussions about the health of its players, with many pros suffering multiple instances of concussion throughout their careers and going on to develop serious health problems in later life.

Because of this, the Cardiff University researchers developed a 3D printed material called “C3” that is designed specifically to absorb impact and help prevent head injuries — particularly in sport, but also for military applications.

Excitingly, that research is one of many instances of engineers creating shock-absorbing 3D printed materials that could protect the next generation of sportsmen and sportswomen.

Taking cycling up a gear

Cycling is a sport that is highly dependent on two things: the physical stamina of its athletes, and the technical quality of its equipment. And in the race to develop the most high-performance bicycles out there, some notable companies are using on-demand manufacturing processes like CNC and 3D printing to create a whole range of futuristic bike parts.

One of the most important piece of a bike is its frame, the metal structure that holds all the other pieces together. Most frames are made from steel, aluminum, titanium or carbon fiber. Surprisingly, it’s actually possible to create a high-performance bike frame using CNC machining, as proved by Pole Bicycles last year when it unveiled a frame CNC machined from an aluminum alloy.

On Pole Bicycles’ unusual frame, the front and the rear triangles are made of three parts bonded together with glue — a process the company likens to similar methods used in the automotive and aerospace industries.

In addition to CNC, 3D printing is also making its mark on the contemporary cycling world. Italian company Pinarello recently created 3D printed handlebar components for its time trial bikes. And these weren’t just low-key experiments: the 3D printed gear has been used by pros like Chris Froome, a four-time winner of the Tour de France.

With experience in the on-demand manufacturing of everything from golf clubs to car parts, 3ERP has the ability to realize your next sports equipment project. Get in touch to find out more about our on-demand manufacturing services.