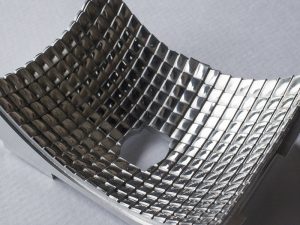

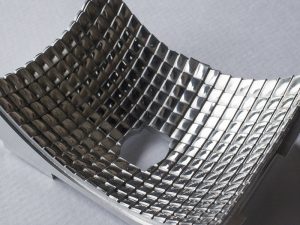

Typical CNC Machining Parts We Offer

Our titanium machining process is suitable for various custom parts, from rapid prototypes to low-volume or mass-production orders.

| Applications | Precision titanium machining parts with excellent strength-to-weight ratio, mechanical properties, accuracy, and repeatability. 3 and 5-axis CNC milling available. |

| Strengths | Corrosion resistant – high accuracy – repeatability |

| Weaknesses | Greater geometrical restrictions than 3D printing |

| Lead Time | < 10 days |

| Wall Thickness | 0.75 mm |

| Tolerances | ±0.125mm (±0.005″) |

The most commonly used pure titanium and has excellent corrosion resistance. Its low density, superior strength-to-weight ratio, and good formability make it the preferred material for many aerospace, automotive, medical, and consumer applications.

Tensile Strength (Ultimate): 240 MPa, 34800 psi (Yield): 170 – 310 MPa, 24700 – 45000 psi

Shear Modulus: 45 GPa, 6530 ksi

Elongation at Break: 24 %

Hardness (Brinell): 120

Density: 4.51 g/cc, 0.163 lb/in³

Maximum Service Temp: 600 °C, 1100 °F

The Top 6 Reasons:

One-off titanium prototypes or large-volume production. We can handle any size of order.

We can take your project from engineering design to delivery faster and cheaper than competitors.

Finished parts ship within 7 days (or quicker) with a 99% on-time delivery record.

Our engineers have extensive experience in various industries, so they can handle any project, no matter how challenging it seems.

Our aerospace and medical parts fabrication processes exceed the industry's highest standards. Advanced tools guarantee optimal precision and tight tolerances.

We provide a wide selection of aesthetic and functional coatings and finishes to meet any needs.

As-Machined: The most cost-effective and simple finish, As-Machined is the go-to choice for situations where a smooth surface won’t be exposed or its appearance isn’t of utmost importance.

Bead-Blasted: This creates a beautiful matte finish with a uniform texture. This approach is achieved by using abrasive media such as glass beads and aluminum oxide, producing a consistent finish.

Anodized: This method creates a robust oxide layer on the surface of the titanium that can also be colored in various shades. Ideal for outdoor applications, as the protective film safeguards against rust and corrosion!

Powder-Coated: Powder coating is an economical finishing process used on machined titanium parts to add a unique variety of colors, textures, and corrosion resistance. By melting and then curing the polymer-based powder onto the surface, it achieves a strong and durable finish.

CNC machining services are an integral part of manufacturing in the aerospace industry. A high level of precision is essential for safety-critical aircraft components. Machinable parts include prototypes, fuel panels, landing gear, and engine mounts.

The marine industry requires very durable parts that must withstand harsh weather and environmental conditions. 3ERP offers a range of CNC titanium machining services that create highly durable components for commercial and recreational marine vessels, such as ship propellers, outboard motor parts, ship engine parts, and marine pumps.

Medical equipment and devices must be extremely precise and accurate to ensure patient safety. 3ERP can produce precision-engineered titanium components using CNC machining. Our services are used in various medical devices such as orthopedic titanium implants, dental products, and surgical tools.

in 4 Steps

Fill in the request-a-quote form and upload your 3D CAD file.

We'll send you a quote and Design for Manufacturability (DfM) report.

Review your quote, place your order - and we'll manufacture your part(s) according to the specifications.

Your CNC machined parts (or prototype) will be delivered to your door.

Our titanium machining process is suitable for various custom parts, from rapid prototypes to low-volume or mass-production orders.