Foam Machining Services

Custom Foam Machining Prototype & Production Parts, Worldwide Delivery in Days

- Foam Prototype & Low-Volume Production

- 50+ Machining Foams

- Tolerance as tight as ±0.05 mm

TRUSTED BY OVER 1K+ COMPANIES

3ERP specializes in foam machining for a variety of applications. We offer custom cutting, machining, and prototyping services for foam and other different materials to create intricate shapes that can be used in a wide range of projects.

What we create

From prototypes, molds for composites, and concrete molds to foam inserts and modelings – 3ERP foam milling and machining can help make your ideas come to life!

How we do it

We use advanced CNC machines, foam milling routers, and laser cutting techniques to ensure exact specifications on all our projects.

Our experienced team is dedicated to providing you with the highest quality of craftsmanship and attention to detail.

Whether you’re a small design team or mass production manufacturer, 3ERP can help turn your ideas into reality with exceptional accuracy and quality results.

Contact us today for more information about our custom foam machining services!

Foam Machining Processes

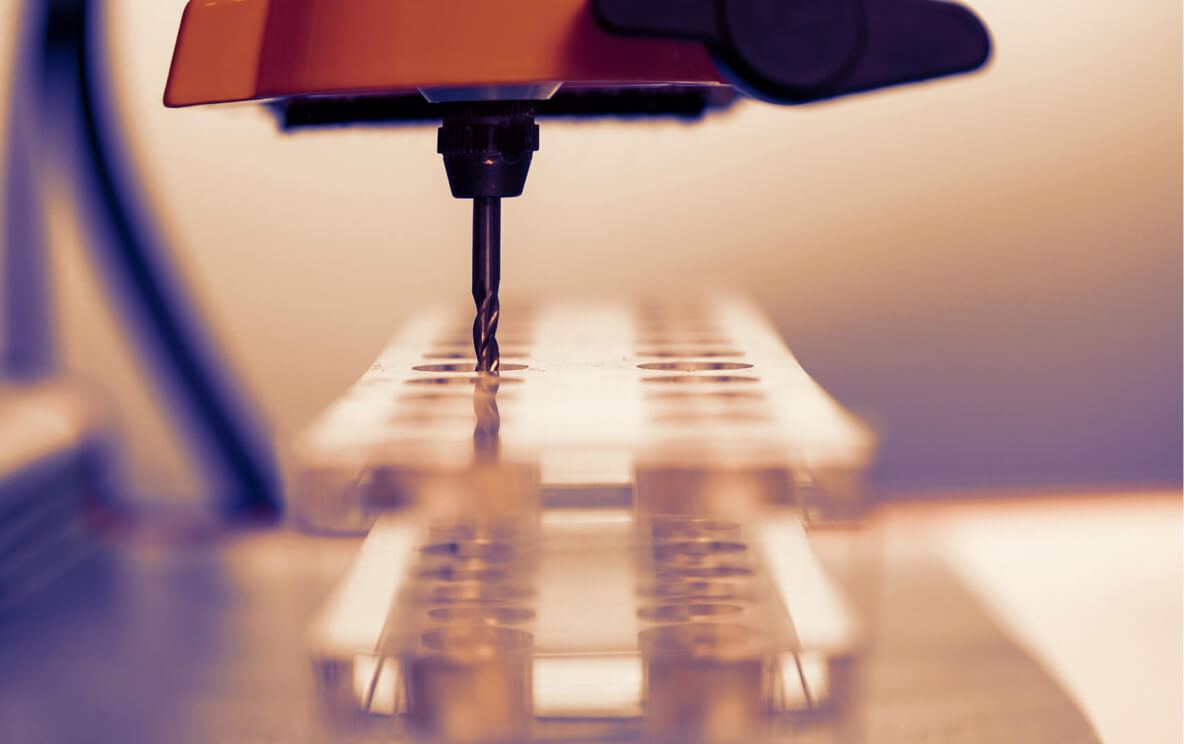

Milling Foam

CNC milling is the common processes to machine foam prototype or production parts from solid blocks.

Lathe Foam

CNC lathes and swiss machines are the most efficient machine to make round shaped foam parts from bars or tubes.

Advantages of foam machining

The Top 3 Reasons:

Mold-free

One of the main advantages of foam machining — especially for prototypes and short-run production — is its ability to create parts without molds or support structures. The most expensive part of injection molding is creating the metal tooling; with CNC machining, however, that stage is not required.

1 Adaptable

Because machined foam parts are made directly from a foam sheet or rod using a digital file, it is easy for engineers to make small modifications to the digital design between iterations. And since they do not have to make new tooling, there is little cost involved in upgrading and updating the part.

2 Precise

The range of machine tools allows for total control over a part’s final appearance, offering fine trimming and cutting capabilities not available to injection molding or 3D printing equipment. Machined parts are also free from 3D printer layer lines and seams from injection molding parting lines, which can be unsightly to view.

3 Our Services

Our industry experience combined with the latest technologies allows us to create complex shapes and intricate details in a range of foam and plastic material.

We offer a full range of machining services, including cutting, routing, milling, drilling, and much more for foam and other materials.

Advanced machining capabilities include rapid prototyping, jigging and fixturing, complex geometries, and precision tolerancing.

We can work with a variety of materials such as polystyrene, expanded polyethylene (EPE), closed-cell foam, EPS (expanded polystyrene), XPS (extruded polystyrene), and Polyurethane Foam to your exact project specifications.

Our experienced team of engineers is equipped with state-of-the-art CNC machinery and cutting equipment capable of producing foam parts quickly and accurately according to customers’ drawings and specifications.

What is Foam CNC Machining?

Foam CNC machining uses computer numerically controlled (CNC) tools to cut and shape a wide variety of foam materials. This type of machining is used in the creation of products ranging from machined components to aerospace structures.

To produce a foam-machined physical part involves several techniques, including drilling, routing, cutting, and sculpting.

The most common types of foam used in this process include polyurethane foam, polystyrene foam, and ABS plastic.

Foam CNC machining offers many advantages over traditional methods of manufacturing.

It is much faster than other processes, such as hand carving or manual milling. This is because computer-controlled tools can move much faster than a human operator.

The results are more precise and detailed, making it possible to create complex designs in a fraction of the time it would take with traditional methods. Additionally, foam CNC machining is very cost-effective.

How does foam CNC machining work?

Design

First, the object to be machined is designed in a computer-aided design (CAD) program. This allows for precise measurements and control over the design of the object.

Coding

Once the object has been designed, a code is generated that the CNC machine uses to control its movements. This code is written in a language specific to CNC machines, such as G-code.

Setup and Programming

The next step is to set up the foam material on the machine and program it using the code generated from the CAD file. This step requires a skilled technician to adjust the machine for the specific type of foam being used and enter the code into the CNC machine.

Foam Cutting

The foam-cutting process begins with setting up the cutting tool, such as an end mill or router bit. Once the cutting tool is set up, it can be guided along the programmed paths to remove excess material from the block of foam to create the desired shape for the foam product. The cutting tool generates a lot of heat, so it’s vital to keep the foam cool during cutting.

Finishing

After the parts are cut out from the foam, they need to be finished. This can involve sanding the edges, rounding corners, polishing the surface, or applying a hard coating to protect the foam product.

What kinds of foam can be machined?

A wide variety of foam materials can be machined using CNC technology, including:

- Polyurethane foam

- Neoprene foam

- EPDM rubber

- Flexible plastic foams

Additionally, our CNC machines are capable of cutting high-density rigid foam materials like polystyrene and polyisocyanurate.

See why Our Customers love us

“ 3ERP is the most reliable plastic molding company we have used. After seven orders, they haven’t let us down in terms of quality or delivery. I wouldn’t hesitate to recommend them to other companies looking for rapid-molded parts.”

“ I had a project with a couple of complex plastic molding parts. 3ERP took care of it without any fuss: DFM confirmation, T1 samples confirmation, then the final parts arrived quickly. Overall, working with them was really easy.”

“ Thanks for shipping out our molding parts so quickly! Quality was high, as expected, and the laser engraving and pad printing finishes were especially good. We plan to use 3ERP again for plastic moldings.”

Mark Peterson

Outsourcing Manager

Get Your Foam Machining Parts Done

Upload a CAD File

To start, simply fill in a few information and upload a 3D CAD file.

1 Quote & Design Analysis

You'll receive a quote shortly, and we'll send you design for manufacturability (DFM) analysis if necessary

2 Order Confirmation

Once you review the quote and place your order, we'll start the CNC manufacturing process, and surface finishing afterward as well if needed

3 Parts are Shipped!

Your CNC prototypes or production CNC machining parts will be inspected and delivered straight to your doorstep

4 What are the benefits of 3ERP’s foam CNC machining services?

Our foam CNC machining services offer customers a variety of benefits, such as:

- Quick turnaround times to meet tight deadlines.

- Cost efficiency due to reduced material waste and time invested.

- Highly accurate and precise results.

- Low minimum order quantities for small projects or prototypes.

- Versatility with the ability to cut complex shapes and patterns with precision.

- Increased design flexibility which can help find solutions to challenging projects.

- Environmentally friendly production process with no hazardous materials or gases involved.

Applications of foam CNC machining services

Foam CNC machining can create complex, precision parts with numerous applications. Examples include:

- medical devices

- automotive components

- architectural accents

- aerospace components

- and many more…

The intricate nature of the parts created using foam CNC machining allows for precise measurements to tight tolerances that are usually impossible with other methods.

Additionally, foam CNC machining services can produce highly detailed models and prototypes for product development and testing.

CNC machining of foam offers a range of benefits to many industries, such as automotive, aerospace, and medical. It is a cost-effective alternative to traditional manufacturing techniques that require complex tooling and specialized machinery.

Different types of foam machining

Foam machining services include die cutting, routing, grinding and carving, laser or waterjet cutting, and sandblasting.

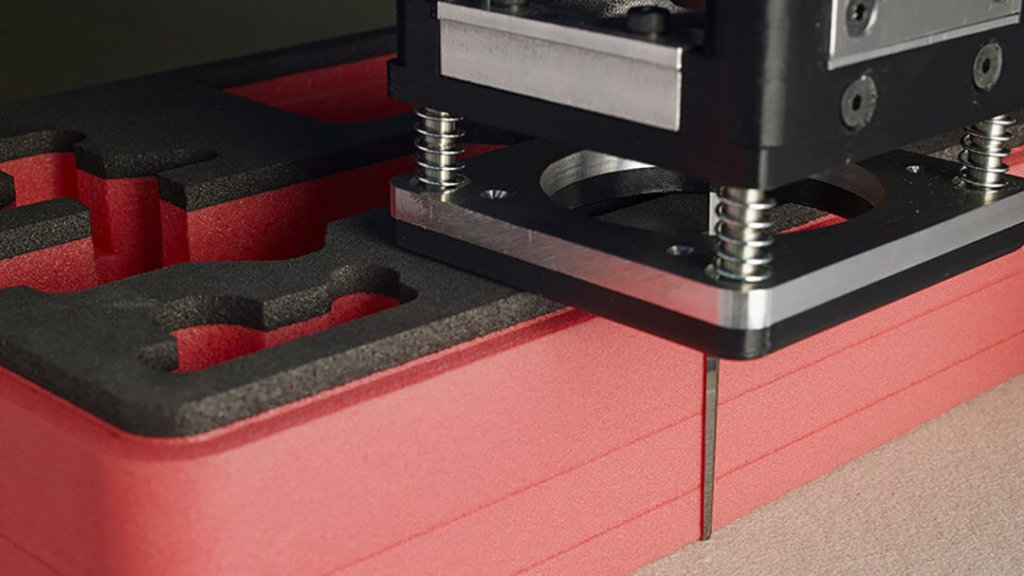

Die cutting

A process that uses precise dies to cut foam shapes into pieces with precision.

Router machining

Allows for accurate control over intricate details in the foam material while grinding and carving allow for rapid shape and size reduction.

Laser or waterjet cutting

Used to cut intricate shapes with a high level of accuracy, while sandblasting gives foam materials a textured surface finish.

CNC foam machining

Ideal for many projects requiring a high level of accuracy and precision. No matter what kind of project you have in mind, foam machining can handle everything from intricate shapes to large-scale products. Foam machining provides the highest quality results at an affordable price.

Advantages of working with 3ERP

As an ISO9001-2015 certified company, we are proud to offer our customers the highest quality machined foam products at competitive prices, with unparalleled customer service.

- Commitment to customer service excellence with a dedication to meeting deadlines and exceeding expectations.

- Rigorous quality control procedures to ensure the best results.

- Competitive pricing structures to help keep costs down while ensuring quality is maintained throughout the process.

- Expert technical support available to answer questions and provide advice on foam material selection, machining techniques, manufacturing solutions, and more.

- Onsite design engineers to assist with product development, prototyping and production runs.

Contact us today for all your foam fabrication needs.

Start Your Project With A Free Quote