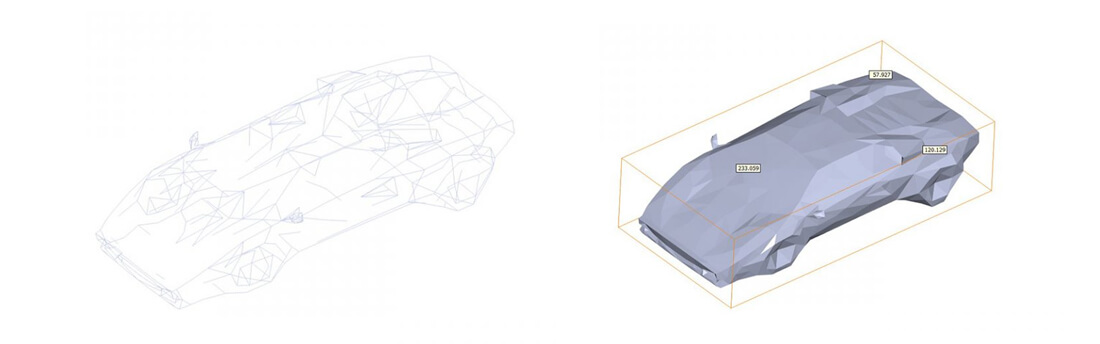

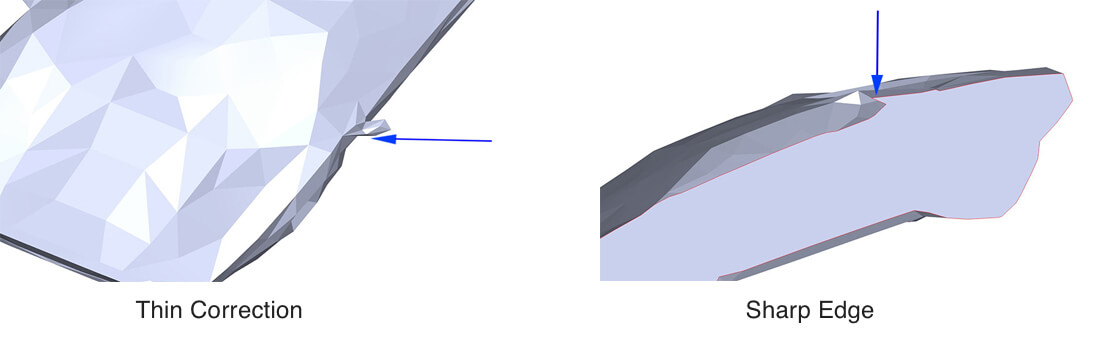

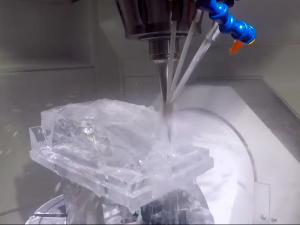

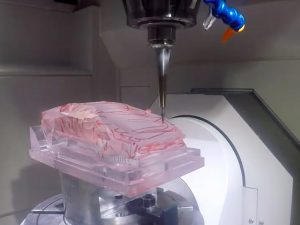

This is an old project we did for UN in 2013. In order to stay within budget, we made it using SLA (stereolithography) and painted it black. The result we got was OK, but not brilliant. This is due to the limitation of the SLA process: the visible layers of the build process is the main problem. Recently, we came up with the idea to make this prototype using 5 axis CNC milling. In order to find a better solution for similar kinds of projects, meanwhile, we test out the accuracy and stability of our new machine.