Electronic devices like personal computers generate heat as they are operated. Electricity runs through the various wires and components of the device, encountering resistance as it goes, and this resistance generates heat, rapidly elevating the temperature of the device.

Left unchecked, this heat can have disastrous consequences for the device: components like the central processing unit (CPU) are fragile and are not capable of withstanding extremely high temperatures; overheating can therefore lead to malfunction or permanent damage.

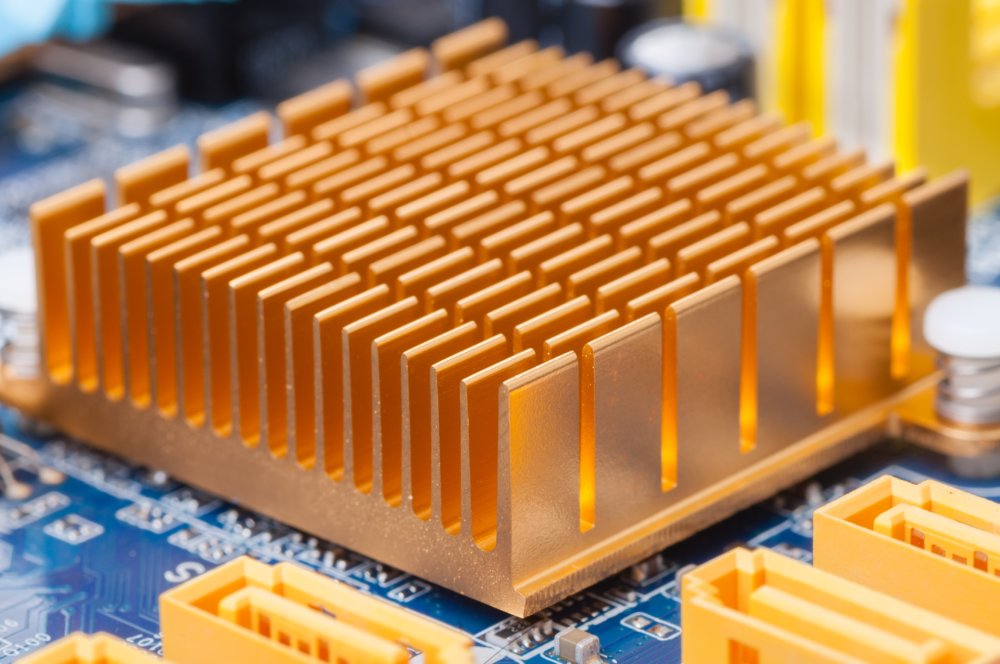

Fortunately, many electronic and mechanical devices prevent this problem by using heat sinks (or heatsinks): special components that dissipate heat from important areas of the device in order to keep it cool and functioning.

Despite their small size, heat sinks are incredibly important components and can be made in lots of different ways. This article looks at how heat sinks work, the advantages of heat sinks, the different types of heat sink, and how heat sinks are made.

What is a heat sink?

A heat sink is a kind of passive heat exchanger whose function is to regulate the temperature of an electronic or mechanical device. It transfers heat from a heat-generating component to a fluid (air or liquid coolant), allowing the heat to dissipate away from the device.

Heat sinks work by using a thermal conductor to take heat away from a heat source, drawing it towards its own large surface area that makes contact with the cooling medium, i.e. air or another fluid. The need for a large surface area is why heat sinks typically consist of a base connected to a number of very narrow fins or pins: this form is the best way of fitting as much surface area as possible into a given volume.

Used in a range of industries, heat sinks are often used to cool computer components like CPUs and GPUs, as well as power transistors and lasers.

Determining whether a heat sink is needed — and what kind of heat sink — involves establishing the maximum junction operating temperature of a circuit. If the operating temperature is exceeded, it will lead to part malfunction or breakage. In general, components with a lower maximum operating temperature (or those that simply generate a lot of heat) require more effective heat sinks.

Advantages of heat sinks

The core function of a heat sink is to regulate temperature and prevent overheating. This provides advantages such as the following:

- Prevent overheating

- Prevent part failure or breakage

- Provide heat in case temperature drops too low

Types of heat sink

Heat sinks generally consist of a solid base with protrusions sticking out of it. But the form and size of these protrusions affects how the heat sink performs. The most common heat sink varieties include:

- Pin-fin heat sink: Pin-fin heat sinks have pins that extend from the base. They offer the largest surface area of all heat sink types and are best in low airflow (or random/multidirectional airflow) situations. The pins can have different shapes:

- Cylindrical

- Elliptical

- Square

- Plate fin heat sink: More common than pin-fin heat sinks, plate fin heat sinks have rectangular fins that extend from the base. They are the best type of heat sink when airflow is unidirectional.

- Flared fin heat sink: A variation of the plate fin heat sink, flared fin heat sinks have a flared fin arrangement and decrease flow resistance.

Some heat sinks have attached fans, and heat sinks of this type may be called active heat sinks or fan-cooled heat sinks. Those without fans may be called passive heat sinks. Fans provide a constant source of airflow, which improves the functionality of the heat sink.

Heat sink materials

Heat sinks are typically made of aluminum alloys or copper, with material usually determined by application, heat intensity, production method, and budget.

Aluminum heat sinks are usually made from aluminum 1050 (very thermally conductive but low strength) or aluminum 6060, 6061, or 6063 (less conductive but with better mechanical properties). The most affordable heat sinks are generally made of aluminum alloy.

Copper heat sinks offer excellent thermal conductivity — it is twice as conductive as aluminum — as well as corrosion resistance, antimicrobial resistance, and other desirable properties. This makes copper heat sinks something of a premium choice; however, copper is both more expensive than aluminum alloys and generally more difficult to form.

Heat sink attachment methods

The heat sink attachment method is the way the heat sink is mounted to the component whose temperature it is attempting to regulate, e.g. a computer’s CPU.

Attachment methods include thermally conductive tape (for low-mass heat sinks), epoxy (strong but irreversible mechanical bond), clips, wire form Z-clips, brass/plastic push pins, or threaded standoffs (for very large heat sinks).

Factors that affect heat sink performance

Several variables affect how a heat sink performs and how effective it is at dissipating heat from a component such as a CPU. Important heat sink performance factors include:

- The thermal conductivity of the heat sink material (e.g. copper or aluminum alloy)

- The size of the heat sink

- The type, number, and arrangement of fins on the heat sink

- The size of the ducts between each fin

- The heat transfer coefficient

- The air flow rate

How to make heat sinks

How do you make a heat sink? That depends on several factors, such as the size and material of your heat sink, and the kind of manufacturer making it. Manufacturing heat sinks can actually involve a range of production technologies, including casting and CNC milling.

Extrusion

Extrusion, the process of forcing hot metal billets through a steel die, is the most common way of making aluminum heat sinks. It is a fast, effective, and economic method for making heat sinks out of ductile materials like aluminum 1050. Extruded aluminum heat sinks are typically anodized before use.

Skiving

Skiving or scarfing, the process of cutting material into slices, is a common manufacturing process for the production of plate fin and flared fin heat sinks. The process allows for thinner and more closely packed fins than extrusion, and also provides a level or surface roughness, which slightly increases the total surface area.

Casting

Casting, the process of pouring molten metal into a mold, is another way to make heat sinks — aluminum or copper. Pressure die cast heat sinks can have a high level of complexity and offer excellent mechanical properties. Die casting is also sometimes used to make zinc heat sinks.

Milling

Milling, the subtractive process of cutting material from a blank workpiece, is an affordable way to make heat sinks with virtually any geometrical shape, from materials like aluminum alloys. Milled heat sinks (or machined heat sinks) may be more expensive than alternatives, especially in large quantities, but they can also be made very quickly. Learn more about aluminum machining.

3D printing

Recent advancements in copper additive manufacturing have made 3D printed heat sinks a viable alternative to their traditional counterparts. Powder bed fusion and directed energy deposition technologies have been most successfully used for this purpose.

To make a heat sink with 3ERP using a process like CNC machining, extrusion, or low-volume casting, contact us for a free quote.