For most people, the knowledge about manufacturing and prototyping technologies of today consists mostly of what they learn in school or what they stumble upon on the internet.

Many are at least vaguely familiar with the process of 3D printing, which can offer sustainable and eco-friendly manufacturing possibilities. But even though 3D printing is becoming more popular, it still can’t match the opportunities provided by the variety of CNC machines that are used by countless companies around the world.

Even though it’s much less known to people outside of the industry, CNC machining became no less than revolutionary when it was introduced, and remains an irreplaceable manufacturing method that is vital to a range of industries, including aerospace, medicine, and the automotive industry.

But what are CNC machines? And how can you use them to design various parts?

Let’s explore the process of designing parts with CNC machining and the decisions you will need to make below.

What is CNC Machining?

CNC machining is a type of machining that uses computer numerical control technology to perform specific tasks and movements.

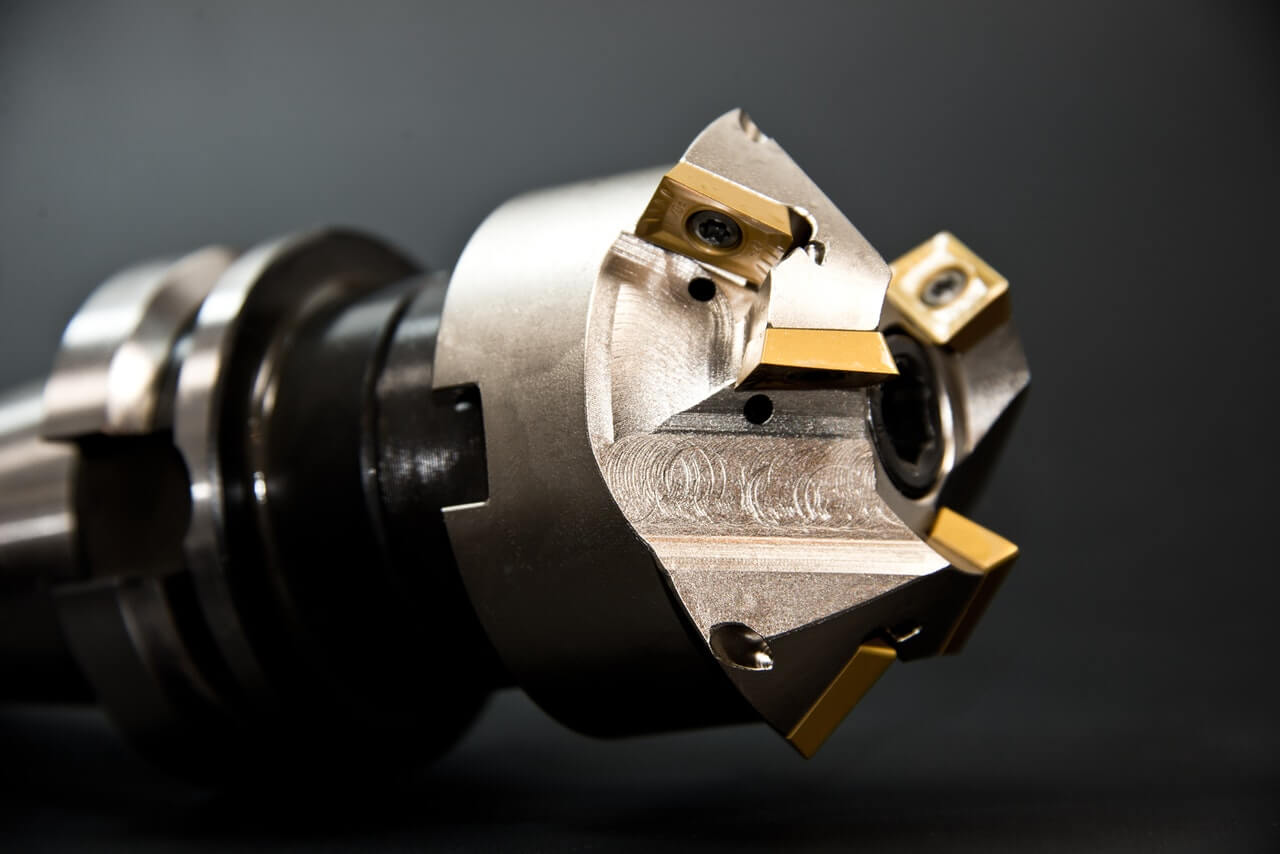

It takes a stock piece of material and then uses a range of drills, lathes, and mills to cut away at it until the part meets the exact dimensions of the digital design that was used as a basis.

Unlike 3D printing, which molds materials together to form a shape, CNC machining is a subtractive process that cuts away layers of the material until the desired shape is achieved.

Another important distinction is the CNC process itself. Unlike manually-operated machines, the process with CNC technology is entirely automated, which means that much less supervision is required to execute a project.

What’s more, the automated process also means that the likelihood of human error is reduced to a minimum, and each copy of the part is identical to the original, down to the smallest identifiable details.

Yet, even though the process can be very efficient, there are many things that need to be considered in order to avoid costly mistakes and ensure that the project goes smoothly.

Let’s go over some of the most important considerations when it comes to CNC machines to give you a better understanding of the process behind designing various parts.

Types of CNC Machines

Even though CNC machining may seem like a specific enough term, it actually encompasses a range of different CNC machine types, such as a milling machine or a lathe machine.

Different machines have their own strengths, as well as typical uses, which are important to know if you want to achieve the best results.

A lathe machine is a popular option, especially for designing cylindrical shapes, because it provides versatility and cost-effectiveness that’s hard to match by other types of manufacturing.

Another standard option is the CNC router machine, which routes tool paths in 3-axes, offering a wide range of possibilities for creating parts while also reducing the wasted materials to a minimum.

Then you have two types of milling machines – vertical CNC milling machines and horizontal CNC milling machines. They both use a cutting tool aligned with the machine’s bed, with the main difference being that one of them is vertical, and the other is horizontal.

Possible Materials

When designing and manufacturing a part, one of the first major decisions you’ll need to make is the type of material that you’ll want to use.

And the good news is that there is a wide range of material options to choose from when you use CNC machines for prototyping or manufacturing your parts.

Some of the possible factors that you should consider when making a choice include how durable and hard you need it to be, its rigidity, resistance to various chemicals, as well as mechanical functions. In some instances, aesthetic considerations might also play a role, although the other factors should come first.

The great thing is that CNC machining supports a wide variety of different materials, including steel, copper, brass, and aluminum, just to name a few. This means that you can customize your design according to its unique requirements and take advantage of the unique qualities of different types of metals.

In some instances, plastics might make more sense, which CNC machines can also handle with ease. Nylon is probably the most popular option, but you can also use ABS, polycarbonate, Delrin, and even PTFE if you need an option that has a low moisture absorption rate.

Fit Requirements

There’s a reason why NASA and other space programs widely use CNC machining – it’s a manufacturing process that helps achieve unmatched precision with every single part.

But although the technology is incredibly accurate, there is still usually a tolerance for how much a dimension can deviate, even if the numbers are generally minimal.

The standard tolerance for CNC machines is ± 0.125 millimeter, which is almost impossible to notice. But even that can be too big of a tolerance in situations where every fraction of a millimeter matters, and it’s possible to tighten the tolerance to ± 0.050 mm or even less.

When designing a part, you need to know precisely how much tolerances you can allow and weigh the potential benefits of minimizing any deviation against the increased costs of reducing the tolerances beyond the standards.

Consider that, in most cases, CNC machines are already incredibly accurate, so it’s likely that imperfections aren’t going to have any impact on the performance and fit of your part.

You should also think about the design of your part and how it can be changed to fit better with the capabilities of CNC machines.

For instance, when your design requires holes, you might be able to reduce costs by having it go all the way through instead of having the machine drill only part of the way into the material.

You should also consider how thin you can make the walls. That will depend not only on the design itself but also on the material that you end up choosing for your project.

Finally, avoid complex features for your part, as that may limit the selection of CNC machines that can handle the task. Namely, consider if you need dovetail or t-slot undercuts, as they will require special tooling and a lot of effort.

Finish Options

Another key consideration when designing parts using CNC machines will be the finish that you want your parts to have. There are quite a few options to choose from, so you will need to consider whether finish imperfections that don’t influence the performance of the part are something that you can allow.

When using a CNC milling machine, it’s likely that a milled finish, although very precise, will leave visible tool marks, which can have an impact on the aesthetics of the part.

Anodizing is another possible finish – it’s a process of adding an oxide film on metal parts using electrolytes. This type of finish has a few different varieties, with some being more suitable for aerospace and others better suited for engine parts and a range of other applications.

You can also opt for the bead blasting option, which is the process of removing any surface deposits by applying fine glass beads at high pressure. Bead blasting is considered a good choice if you want to make your part more aesthetically pleasing. Still, the process involves manual labor, which means there is always the possibility of imperfections.

Essential Tips

As you can imagine, using CNC machines to design parts can be a complicated process that involves many important decisions, so here are a few tips that will help you achieve the best results.

For one thing, be very careful about familiarizing yourself with the limitations of the materials and the type of machining that you want to use. CNC machining has its strengths and weaknesses, and some parts are just not ideally suited to be made using this technology.

Thin walls, tiny features, and even unusual cavities can all not only skyrocket your project costs but also make the part much less stable.

However, each part design is unique, so sometimes the only way to ensure that you achieve the results that you want is to consult people who have dealt with similar situations before.

If you choose a reliable CNC machining company, they can look at your part requirements and provide you guidance on which tools and machines are best suited to handle the job.

An experienced specialist can also look at your design and provide suggestions about the best materials to use, the finish that would suit your needs, and which machine would provide you with the most cost-effective solution, as well as the most consistent and reliable results.

They can also provide you with specific insights in various situations, helping avoid costly issues such as part deformation in aluminum CNC machining.

Sometimes, you may find that seemingly minor changes to the design that don’t impact your part’s performance can help significantly reduce production costs, so it’s definitely worth it to take the time to explore your options at the beginning of the entire process.