With the promise of low costs and fast turnaround times, Chinese CNC machining services are a popular choice for companies looking to outsource their machining needs. In fact, carrying out CNC machining in China is a vital step for many product developers, since few other countries can match China for cost and efficiency.

That being said, in terms of CNC machining China can be difficult to navigate. There are many Chinese CNC machining companies to choose from, and communication can be more challenging than it is with domestic supply chains — not to mention differences in currency, standards, and Intellectual Property laws.

To make life easier for prospective customers of China CNC machining services, this article provides tips on how to order CNC machining parts from China, looking at the process of outsourcing in Asia while pointing out the common pitfalls one can encounter.

Outsourcing CNC machining to a Chinese specialist

Hardware companies large and small tend to outsource their CNC machining needs to a specialist. Even for prototypes, it often makes sense to use a third-party CNC machining company over an in-house solution, due to the factory space and human skill required to operate machining equipment.

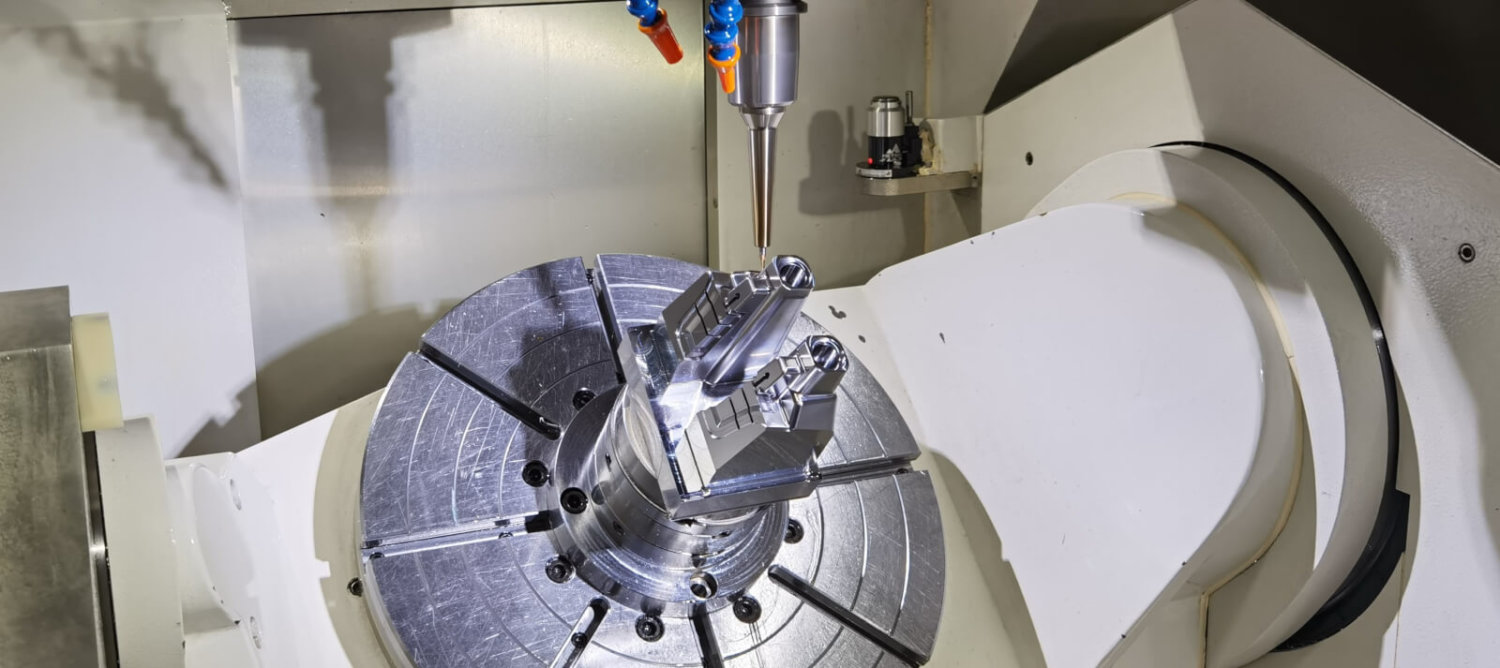

The nature of the CNC machining process and equipment is a big factor here. Unlike desktop 3D printers, CNC machines take up floorspace, require a safe factory environment, and their raw materials are large and heavy metal (or plastic) blanks — not pocket-sized spools of 3D printer filament. For small or medium-size companies, it usually doesn’t make sense to invest in in-house CNC machining facilities, regardless of whether a skilled machining workforce is available.

And a skilled machining workforce is hard to come by. Although CNC machining is perhaps less of an art than manual machining, it still requires a huge amount of knowledge and experience to prepare and execute a machining job. A part made with one grade of aluminum may require a totally different set of machining parameters to a part made with a different grade.

Why choose China for your CNC machining needs?

For the last 20 years or so, Chinese manufacturers have massively increased their adoption of CNC machining equipment, and in doing so have become the go-to solution for hardware companies around the world.

China has always offered some of the world’s most competitive manufacturing rates, and an increase in CNC machining providers has further driven down costs. For their CNC machining China based companies may use Chinese-made equipment or Western equipment, or a combination of both, and most will provide their equipment list on request.

In recent years, machining options have increased in nearby nations like Vietnam and Taiwan with even lower labor costs, but Chinese companies typically deliver better results. This is partly down to Chinese CNC companies being more established, but also due to better supply chains and logistics options in the mainland.

However, CNC machining in China only makes sense in certain situations. If, for example, a company needs a heavy but simple part, it might make more sense to order from a local manufacturer, since shipping may dramatically increase the overall cost of ordering from China.

Furthermore, since the good value of Chinese CNC machining comes from low labor costs, it doesn’t make sense to use a Chinese manufacturer if no labor costs are involved. For example, the mass manufacture of a part (over 100,000 units) may require robotic automation and thus sidestep labor costs altogether, and will therefore have a similar price in Western regions.

See what type of CNC machining parts you can get from a professional Chinese CNC shop

Considerations to make when choosing CNC machining company in China

Identifying a suitable China CNC machining company can seem daunting, but there are a few steps that can be taken before settling on a chosen partner.

- Certifications are one way to assess the suitability of a company. ISO certifications in particular are a good guideline for identifying competent CNC machining companies, although they will not inform you of the scope of a company’s abilities.

- Word of mouth is another helpful way to build a shortlist of potential Chinese CNC companies. Talk to other hardware companies who have contracted manufacturers in the region and find out their experiences working with third parties.

- Demand information from shortlisted companies before making a decision. Once you have established a point of contact, keep asking questions until you are satisfied that the company knows how to execute your project. If they cannot give you a clear answer, they probably aren’t a suitable partner.

- Visit factories if at all possible. This is perhaps not feasible for small companies, but visiting CNC machining facilities in China is probably the best way to assess which companies are the most suitable for a project. In some cases, it may be possible to hire a manufacturing agent to arrange visits to multiple sites in a given region.

- Send RfQs to find out how much a company will charge. A request for quotation isn’t something you need to save for your final chosen company. If you send the RfQ to several shortlisted Chinese CNC machining companies, you’ll get a good idea of who can offer the best price.

- Timeline – Time is precious in every business and it cannot be compromised at any cost. Delivering products to the consumers on time will determine your efficiency and further deals. So, you should ask your manufacturing team about proficiency in terms of the timeline of completion of projects. A reliable company will explain it thoroughly to you without any hesitation. Even you should be more focused on this point.

- Technology- A professional manufacturing company always has the latest technology and different CNC turning and milling machines to involve in this process. They always go with the ever-growing advances in technology and inventions. Also, they have the best team to operate these machines effectively. We would say that when you have a company with the latest technology and extremely skilled professionals for your required CNC turned and milled parts, you won’t need to look further.

- Quality Control – You need to get to know about a company’s CNC machining quality control. You can ask them for complete detail on the quality and efficiency of their parts. Many companies have their quality control section to ensure the best results at any cost. Make sure your company can able to provide you with performance details.

- Superior customer Service – This factor is yet another important consideration. When a manufacturing company will ensure superior customer service, it will also ensure your own performance and client satisfaction as a business owner. In this case, you need to thoroughly discuss with your supplier and they must agree to deliver you with adapted CNC machining services in China that can meet your needs.

Things to remember when ordering CNC machining parts from China

If you have previously used a domestic contractor to fulfill a CNC machining project, then ordering from China should not be greatly different. However, there are a few unique considerations to keep in mind.

- Communicate using universal standards: Ideally, you will want to work with a CNC machining China specialist like 3ERP whose staff can easily communicate in English. Nonetheless, translation issues can arise. To mitigate this problem, be sure to submit a complete technical drawing with your digital files to remove any ambiguity.

- Ask that your partner sign a non-disclosure agreement: Intellectual property is something that scares many customers away from working with Chinese manufacturers. And while IP law is gradually changing, it is good practice to sign an NDA with the CNC machining company that legally prevents the company from disclosing or reusing your designs.

- Factor in shipping times: For prototypes and low-volume orders, Chinese companies can often use priority air mail to deliver your parts within days. For larger quantities and physically larger parts, it may be necessary to use shipping services, which can result in longer wait times than domestic orders. Be sure to discuss shipping times with the manufacturer if you are working to a tight deadline.

- Factor in currency conversion, if applicable: Most Chinese CNC machining companies will accept payment in various currencies, including the US dollar, but there may still be extra fees involved if sending an international wire transfer. Discuss the situation with the manufacturer and your bank if you have any concerns.

3ERP is one of China’s most trusted providers of CNC machining services, for projects of all sizes. Get in touch for a free quote.