Pretty much every product we buy comes in some form of casing or package that needs its own set of manufacturing processes. Over the years, these packages and cases require consistent designs, often produced with the fit and geometry of the product in mind. Today, most packaging equipment is automated for efficiency and faster production times. Packaging machines are controlled with CNC machines, which allow users to reduce labor costs.

However, various forms of CNC technologies such as die cutters and routers (among others) have a lot to offer on this front as well, allowing for a range of design benefits. This particular article will focus on these cutting technologies rather than CNC operated packaging machines.

Advantages Over Other Methods

When it comes to packaging, the routers, mills, cutters, etc. have a few key advantages over other types of technologies. In terms of high-speed low-volume production, these CNC machines will net far more bang for your buck as compared to injection molding and additive manufacturing, for example. While AM can be cheaper in certain instances, it is far slower and oftentimes less accurate. Packaging also needs to be consistent and uniform across the board, which routers and mills are better at.

Injection molding may only be appropriate for high volumes and can thus lead to unnecessary costs on low-volume runs. Injection molding, as the name suggests, requires a mold, which can be time-consuming (weeks or even months in certain cases). Additionally, while injection molding is cheaper in those larger volumes, the upfront costs of mold can dwarf those savings compared to routers.

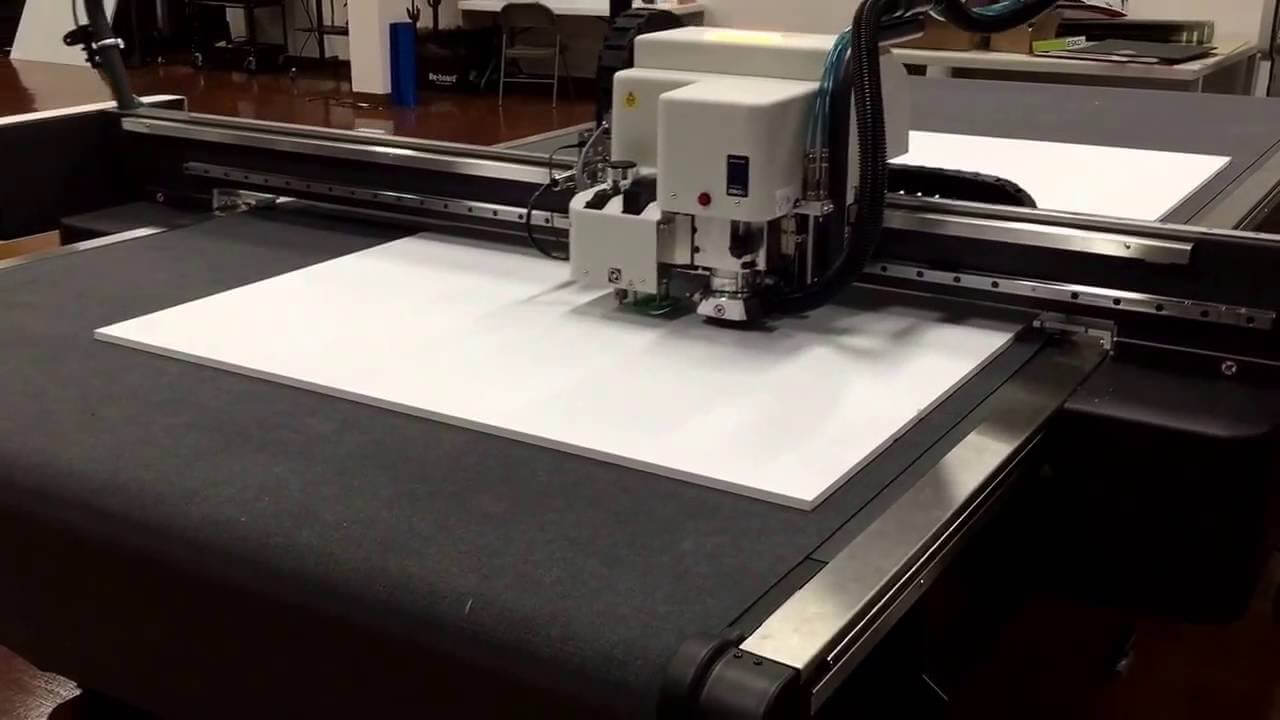

Another important feature that some CNC tables have at their disposal is the ability to digitize the precise shape of the product. In this way, the eventual insert or package production is far simpler. This is especially useful in the programming of products with complex shapes.

On the other hand, it should be stated that subtractive CNC methods are not always the most appropriate way to go. Since packaging often means creating a space for the main product to lay and rest in, large products that require deeper cuts would mean more waste on the material block and more time consumption for cutting their shape through subtractive methods of production. In these cases, another method of production may be more appropriate.

Likewise, not all CNC machines are appropriate for all sorts of packaging, as we’ll cover below. Users need to know what they want from a machine and then decide which machine to get, but the best bet is with a more versatile system like a hybrid multi-purpose router that has a range of different cutting options. CNC machines with a large enough range may be able to process plastics, foams, wood and all other materials that one may consider for their packaging needs.

Plastic Pallets and Containers For Exterior Packaging

Many companies employ the use of plastic pallets for exterior packaging when transporting more general items. Certain shapes that parcels come in, like blocks and cubes, are more universal. As a result, these sorts of pallets can even be reusable across various transport shipments for a range of products that fit them. What CNC cutting offers in this realm is improvements on the older production processes.

Companies like Graco packaging are using a batch of the same pallets for multiple years in their day-to-day operations. These were made using a CNC router and fit the intricate dimensions of the part precisely. They last for a far longer time than ones made from other processes and their client companies tend to use them for all their packaging and transport needs.

Other packaging projects may require a more comprehensive solution that encases the product fully. In these cases, they may employ the use of plastic containers. Corrugated plastic is one such solution, as it can be flexible, durable and easily processed into a variety of shapes. Cutting and water-jetting are common methods to create such storage options.

It’s best to use high-impact resistance plastics for more laborious packaging and transport operations. Any cargo that needs to go into a plane or metal container should be far stronger and will require a 5-axis machine to cut it. The settings and tools can vary from plastic to plastic. For example, PET can be formulated in several ways, being in the form of unreinforced or glass fiber reinforced, for example. It’s best to look up what material you’re going to be dealing with and what spindle speed, flute-type, and tools you’ll need to process it accurately.

Considerations For Foam Inserts

The packaging doesn’t merely refer to the outer box itself as it can also include inserts and foam inner casings, as is often the case with tools and electronics. There is a whole range of materials cutters, routers and mills can process for such more complex packaging purposes. However, different materials and applications require different CNC machines for different materials.

Plastic packaging is probably the most common way CNC cutting tools are used for packaging. Very often these are materials like the common packaging foam one sees inside boxes to prevent transportation damage. These packaging materials can be made from Polyurethane (PU) foam, Polyethylene (PE) or other such common plastics. For example, PU is fairly hard and has a high density and as a result, a router bit is perfect for the job.

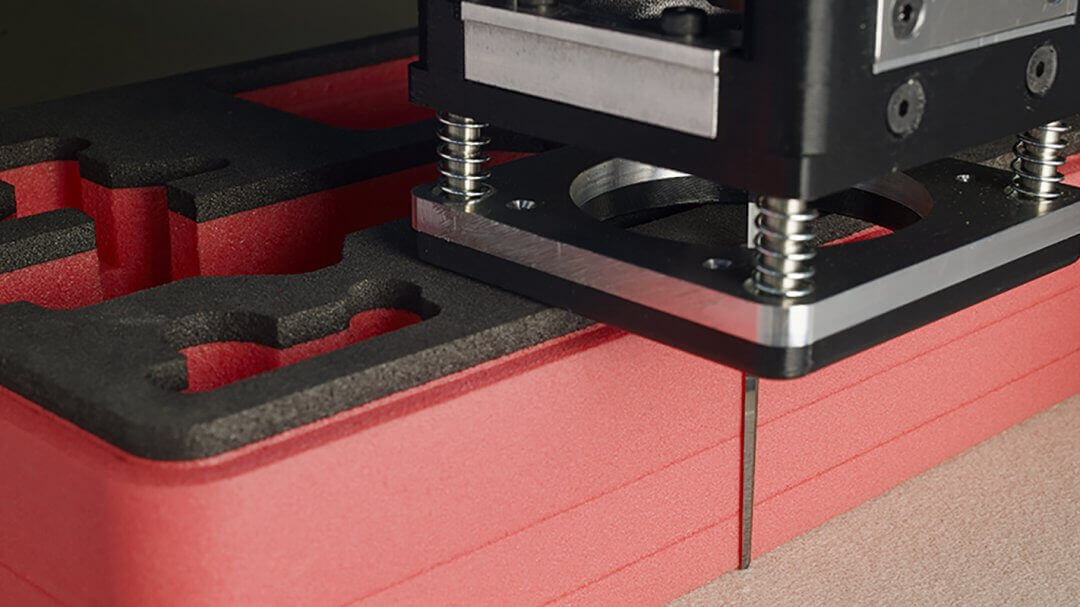

On the other hand, PE foam is lighter and comparatively less rigid, so while routing cutters will tear into it, they may also do it inadequately with unclean cuts in this light material. Cutting lighter foams such as this is not advisable using a router bit, as it can damage the final result and also make it aesthetically unpleasing. PE and other light foams require specific tools, like knife blades.

It’s most beneficial to go with a multi-purpose machine with the proper tools that are programmed to cut all types of foam. This can be a godsend for resolving any queries that may arise with foam processing and allows for a more versatile production process.

This can include CNC tables with either a dual or a triple-Z axis, which can be configured with a routing spindle and one or two different knives in its arsenal. Machines with a triple-Z configuration also have the ability to cut and crease corrugated cardboard. A combination of a specific spindle (either quick-release or collet) along with an oscillating or tangential knife will facilitate cutting of various types of foam including closed or open cell PE. These multi-purpose CNC machines are ideal for those small production runs and can be crucial for prototyping.

Next, choosing the router bit is a crucial part of the set-up. An upward spiral router bit allows for an upward force to be applied to the material, which could cause it to lift and produce unwanted contours or depths of cut, so it’s not ideal for every situation.

Conversely, the downward spiral bit might push the material down, which then results in more material loss than desired. This leaves a larger pocket or smaller part when cutting the profile. Most foam materials do fine under a machine with a twin fluted straight cutter. This puts only a small radial force on the material and will cut the part with minimal distortion and leave a good smooth finish.

Foams often present another problem: holding down the material securely. As these materials can be very light and quite porous, they can be hard to secure with the standard vacuum deck. The most likely solution is using either a vacuum pump or a blower but they each have their own unique characteristics.

Blowers move a greater volume of air than pumps, so if the foam is slightly porous a blower may work better. It has the benefit of less air leaking through the holes during operation, thus provides a more consistent process. Other solutions can be applied in tandem as well. Porous materials can be held down through the application of a low tack plastic film to the underside of the material. This maintains a good seal and can be easily removed later on.

Design Benefits

Items like musical instruments or high-value amplifiers and consoles require delicate to transport. They have to be packed in very tightly and carefully to avoid damage, particularly when it comes to long-haul transportation from city to city. Routers with tangential and oscillating knives have a lot to offer on this front, as the foam packaging of costly musical instruments, lights and props will be able to handle the turbulence of the road.

CNC machining also allows for little grooves and details to be inserted into the design with precision. Such small details can help give more grip to the packaging or the insert. These touches can immensely help keep products safe in their boxes and aid in stopping them from sliding off of a pallet.

Another advantage in terms of design is that they can be designed for reuse more efficiently than with other methods. Stronger plastics and better shaping ability allow for better products that last longer overall.