Commercial travel and vehicle manufacturing is about as heavy and factory-intensive as industries get. Even the smallest car is a massive undertaking with tons of components, never mind massive airplanes or locomotives. These vehicles are meant to operate indefinitely and over long periods of time (sometimes decades).

This also means that many of these vehicles and their components get damaged over the course of years, incurring massive wear and tear from passengers. Previously, manufacturers were reliant on far-off factories that could produce a single part, such as seat covers or plastic components of handrails and grab handles. This often results in long wait times, transport costs and supply-side price gouging. Now, 3D printing is offering a far more economical solution to this issue.

Overall Cheaper & Multi-functional Manufacturing

Figure 1 Image via Angel Trains

When it comes to large vehicles with many components that are breakable, various organizations from the US Air Force to rail companies in the UK are finding 3D printing to be a viable solution. Parts are cheaper to produce using plastic, offering easy customization as well.

This is particularly true for components belonging to planes and trains that have been out of production for years. Maintaining inventory for certain parts can be so costly that suppliers simply stop offering them. This is especially the case with infrequently ordered components. Customers often resort to storing large inventories of such parts or contracting third-party manufacturers. Additive manufacturing is rapidly disrupting this model, however.

While it’s immensely difficult to find a production facility and retrieve copies of such components, 3D printers merely need a model to start off. These can be scanned or even reproduced from scratch fairly easily. Another advantage is that they can improve the part by making various sections lighter and use up less material than many traditional forms of manufacturing.

This mode of production also often entails customization and improvements. In the case of Angel Trains and various UK rail companies, the use of 3D printing also allowed manufacturers to put in braille messages on components of the train so blind passengers could read instructions. This sort of enhancement can also allow companies to personalize such messages or alter them cheaply and easily when necessary.

Just by 3D printing, the grab handles alone, UK rail companies managed to take costs down significantly from the usual £15,000, while cutting production times from two-and-a-half months to about three weeks. Authorities have also predicted that eventually cost savings of 50% per part will be achievable through the use of additive manufacturing and design for 3D printing.

On top of all that, 3D printing also allows for the production of several different types of components as long as the models can work. Not only could they produce parts for seating and passenger trays but also small bits for engineering components, which would ordinarily have to come from separate machines and facilities. This multi-functional aspect allows companies to produce a range of parts and tooling as they see fit with a single device and cheaper materials.

On-demand Production

Figure 2 Bentley Blower

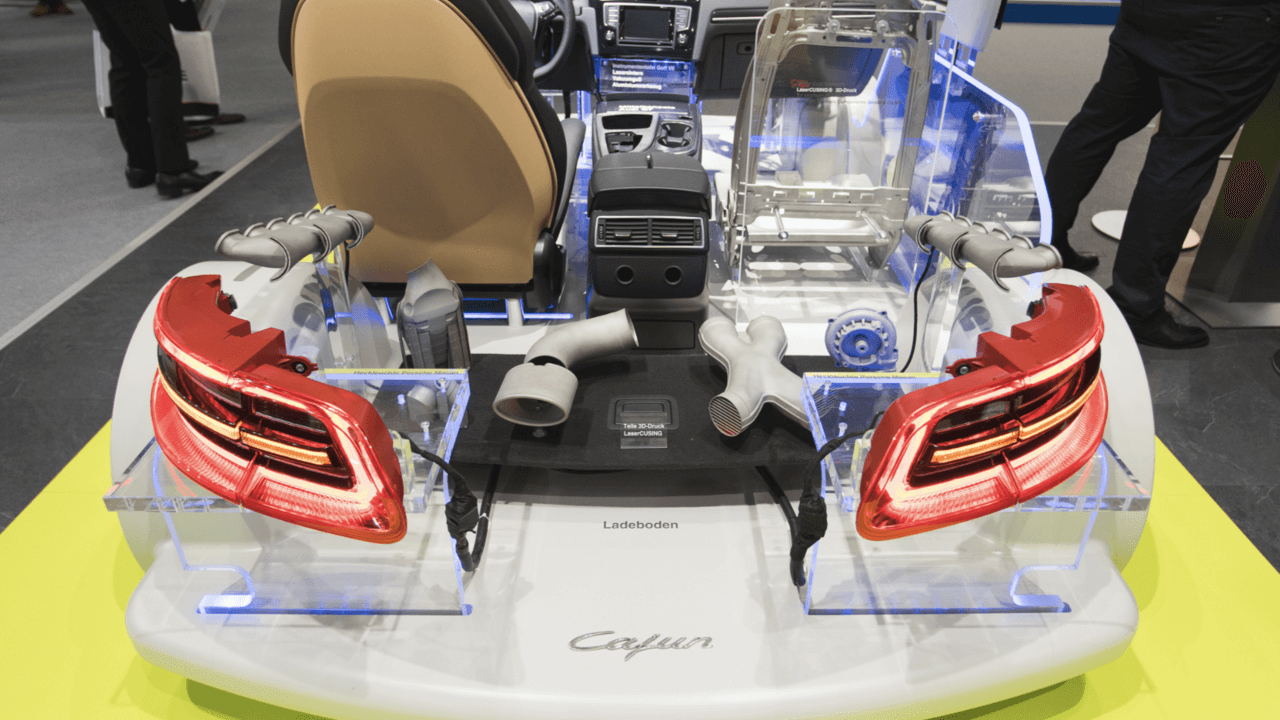

One of the key features of 3D printing is its ability to allow for production on time scales suiting the company rather than the part manufacturer or distributor and without the need for a dedicated facility. For this reason, manufacturing parts that have long since expired is vastly influential in the world of car renovations. Companies such as Porsche have been leveraging this aspect to cut costs on the production of spare buts but on-demand production is bringing back the viability of short-run classic automobile production as well.

Bentley, for example, is using 3D printing to fully recreate older models of its classic lines in what will be the first continuation of a pre-war racecar. In doing so, the company will produce 12 examples of their classic 1929 Bentley 4½-litre “Blower” automobile. The Blowers are also currently one the most desirable Bentley’s among collectors, making it a major attraction for auto-enthusiasts.

Similar initiatives have allowed renovators to fix up old cars all over the world, re-invigorating automobiles once thought impossible to reproduce with faithful renditions of their classic parts. This has been made easier with advancements in 3D scanning, modeling and other technologies.

Localized Manufacturing

The cherry on top of all of this is that 3D printing allows for in-house manufacturing, design and improvements of all of these components. On top of all the other advantages, it also means that prototyping and testing is sped up and localized to the desired facility as well. This has been a major boon for aircraft manufacturers.

In 2019, the US Air Force recently certified its first 3D printed part, which happened to be a toilet cover for one of their planes. Considering that many units in their aircraft fleet are upwards of a decade old, the USAF is turning to 3D printing to dramatically cut down turnaround time and cost of manufacturing spare parts such as latrine covers. This is particularly useful as many of these planes are out of production and spare part delivery can take more than a year.

With 3D printing, not only do they not need to wait on a supplier to provide the parts, they also produce such components at their own facilities. Particularly in the case of the US Air Force, the average age of their aircraft is 28 years old. Many of the factories that made these parts are gone and the delivery and production times for existing ones can be as long as a year.

The aviation industry can be in such dire straits for spare parts that in certain cases, aircraft renovation services scour junked planes for these sorts of components. However, with the aid of 3D printing, the acquisition time for these parts went from a year to 2 days. These parts are now produced in-house, with extensive testing. The USAF will continue to apply 3D printing to other products in the future.